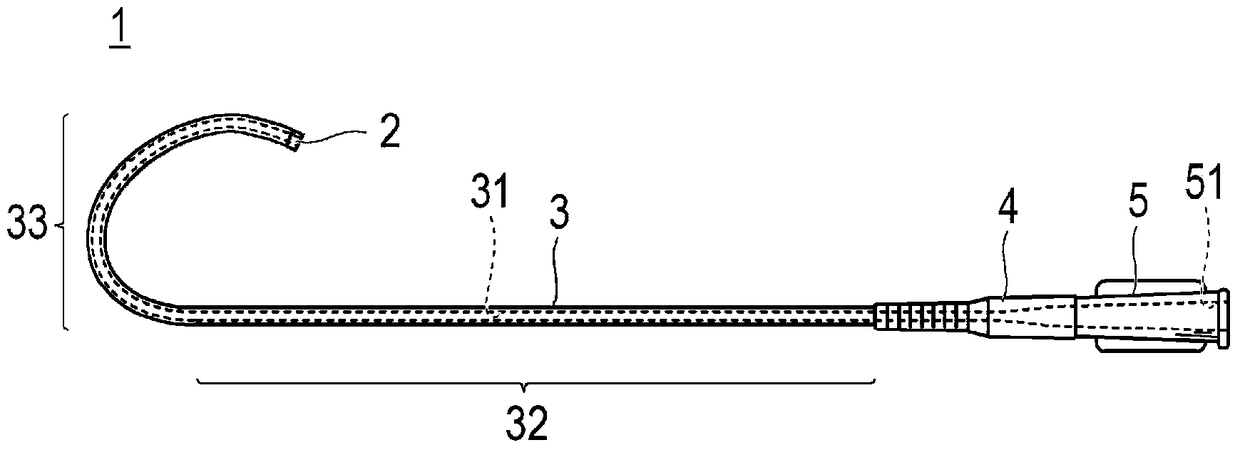

Catheter and its manufacturing method

A manufacturing method and catheter technology, applied in the direction of catheters, coatings, etc., can solve the problem of detachment of the front end of the catheter, achieve the effect of inhibiting performance changes and improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

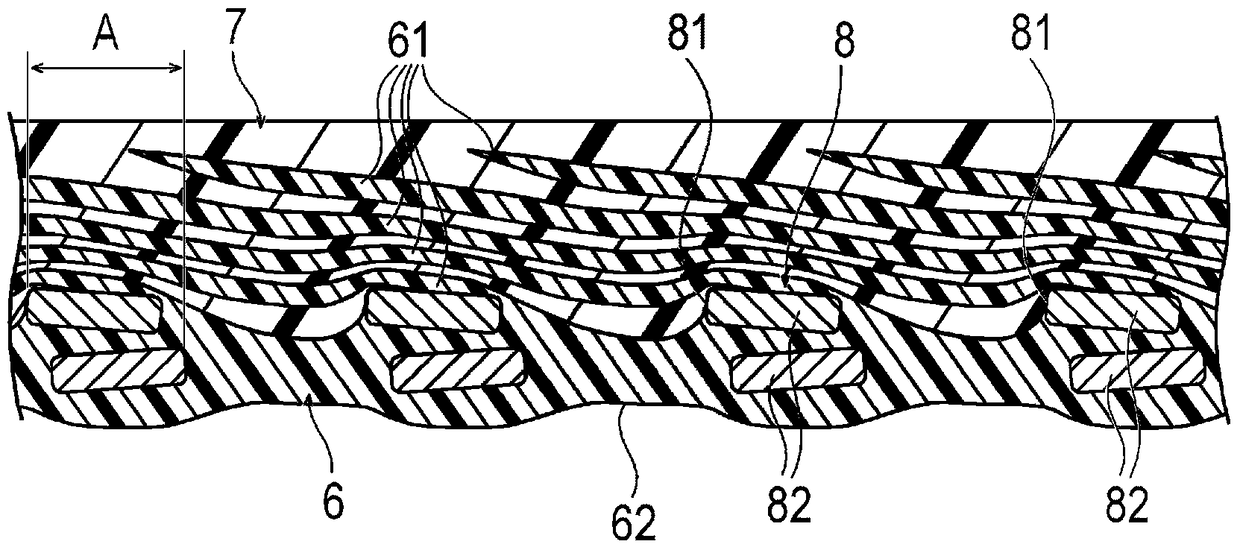

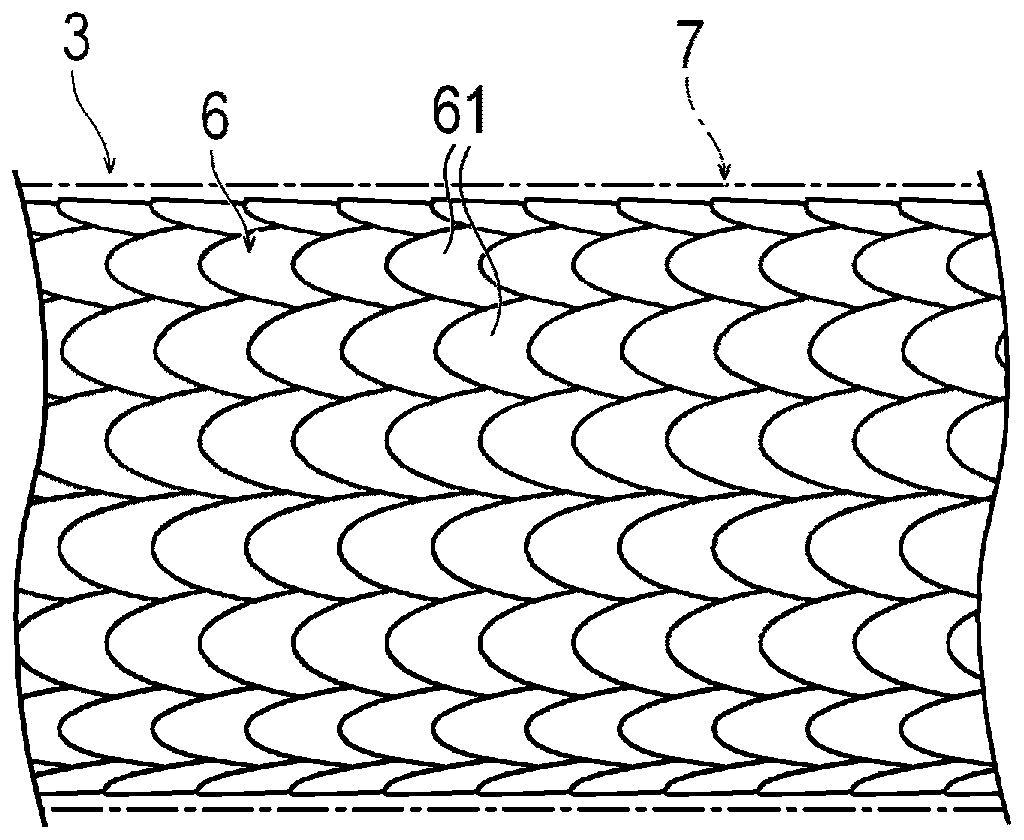

[0083] Use Shore D68 polyester elastomer as the inner layer material, use Shore D52 polyester elastomer as the outer layer material, and extrude Shore D68 polyester elastomer as the inner layer material on the core wire Body, thus making the inner tube. Next, while heating the outer surface of the inner tube, stainless steel planar reinforcing wires (wires) with a width of 110 μm and a thickness of 35 μm were braided and wound at intervals of 0.2 mm (16 braided wires) to obtain an intermediate structure.

[0084] Thereafter, cover the outer layer tube made of Shore D52 as the material of the outer layer on the intermediate structure, and then cover the outer side of the heat shrinkable tube, use the heating source to heat from one end side, and make the heating source slowly toward The other end moves sideways, thereby joining the inner tube and the outer tube. Then, the core wire is pulled out to make a catheter body. Thus, a catheter body having an outer diameter of 2.06 m...

Embodiment 2

[0087] A polyester elastomer of Shore D78 was used as the material of the inner layer, a polyester elastomer of Shore D52 was used as the material of the outer layer, and other conditions were the same as in Example 1 to manufacture a catheter body. Thus, a catheter body having an outer diameter of 2.06 mm, an inner diameter of 1.80 mm, and a ratio of inner and outer diameters of 0.87 penetrating the lumen was obtained.

[0088] Thereafter, a part of the manufactured catheter body was cut in the axial direction, and the cross-section was observed. Figure 10 A photograph taken of a cut surface of the catheter body of the second embodiment is shown in . like Figure 10 As shown, it was confirmed that one protruding portion was formed to extend in the axial direction on the radially outer side of each reinforcing wire constituting the reinforcing member. It is presumed that since the material of the inner layer has a higher melting point and higher viscosity than that of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com