Composite negative electrode material, preparation method thereof and lithium ion battery

A negative electrode material and carbon material technology, applied in the field of electrochemistry, can solve problems such as poor cycle performance and easy damage to the lithium silicate nano-protective layer structure, so as to avoid pulverization and structural damage, improve cycle performance, and avoid structural damage. The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097] For the preparation method of the above-mentioned composite negative electrode material, the process flow chart of the preparation method can be found in Figure 5 , including steps S100-S300.

[0098] Step S100, preparing nano active particles.

[0099] In some embodiments, the preparation method of nano-active particles includes: forming a nano-protective layer on the surface of metal nanoparticles.

[0100] In some embodiments, the method for forming the nano protective layer includes at least one of an oxidation reaction method, a reduction reaction method and a physical coating method.

[0101] In some embodiments, preparing nano active particles specifically includes step S101 or step S102.

[0102] Step S101, performing an oxidation reaction on the surface of the metal nanoparticles to obtain nano active particles.

[0103] Step S102 , performing an oxidation reaction on the surface of the metal nanoparticles to form an oxide layer, and reducing the oxide laye...

Embodiment 1

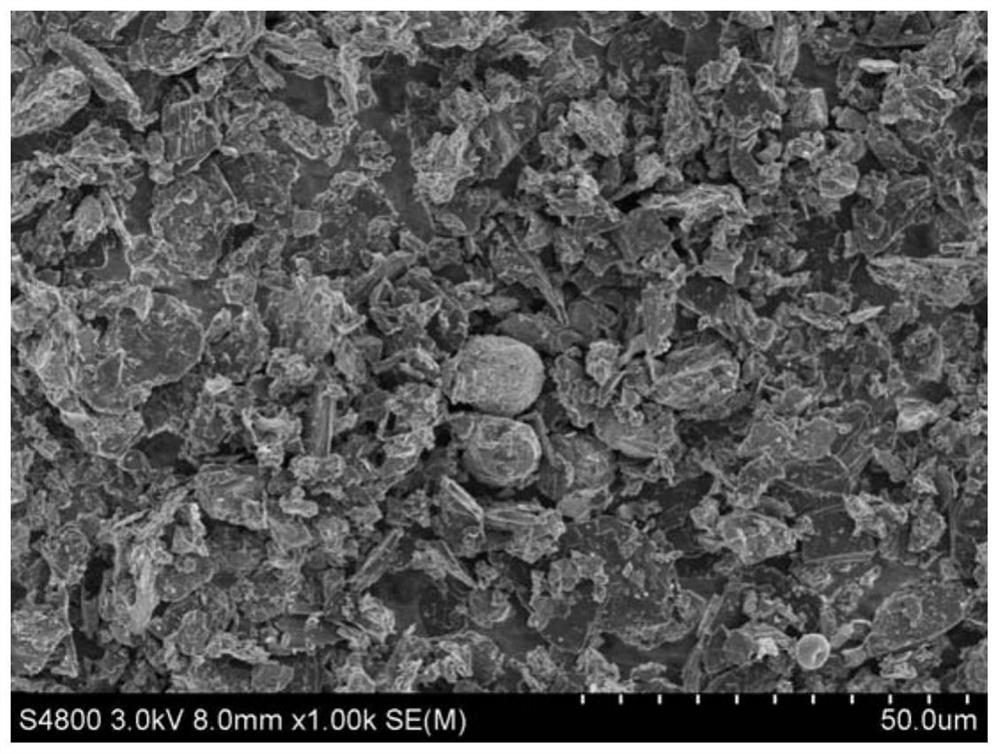

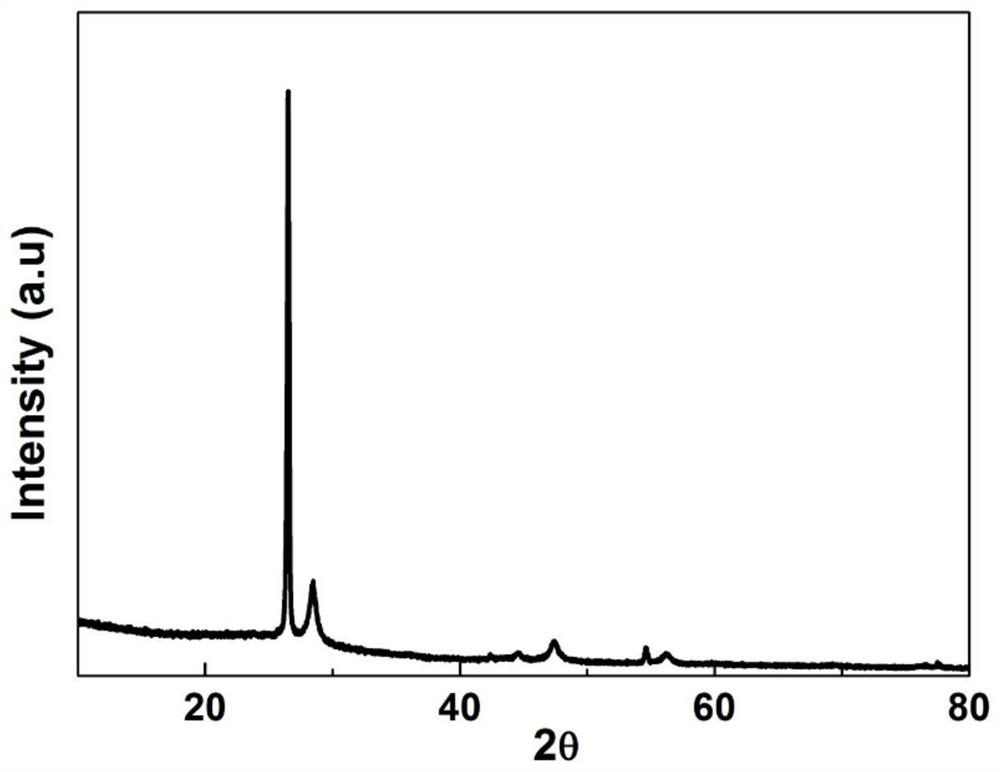

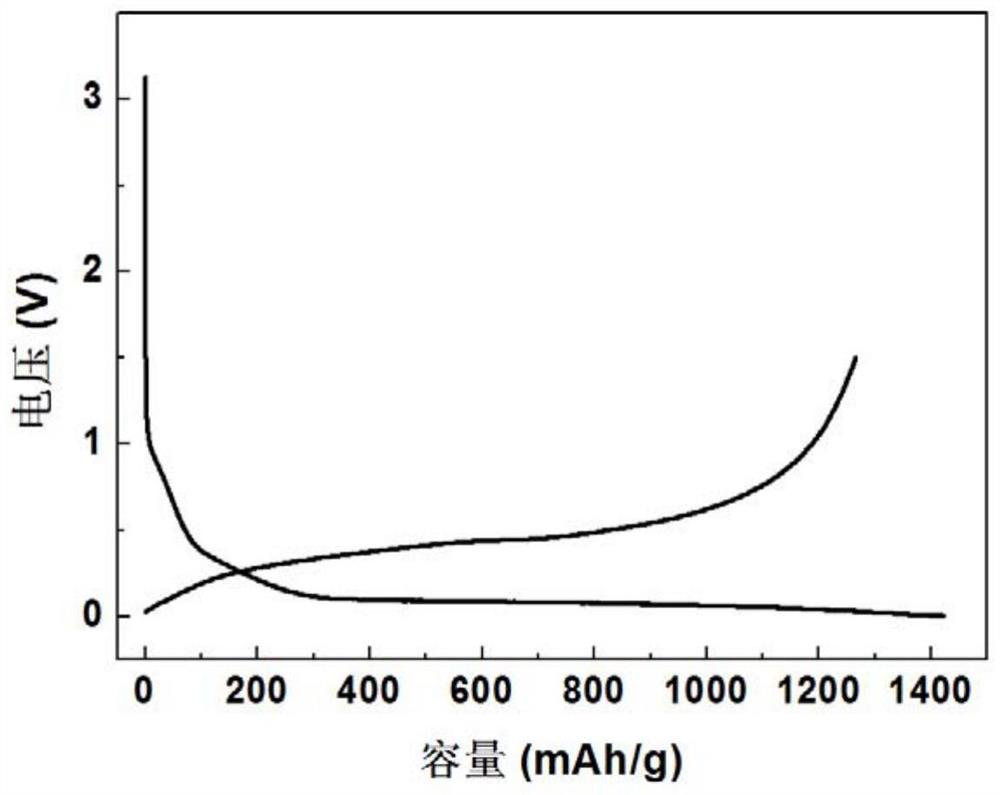

[0125] Disperse nano-Si with a median particle size of 20 nm in ethylene glycol, stir, and then add 5% H 2 o 2 solution, stirred for 4h to obtain Si@SiO containing oxide layer 2 Nanoparticles, SiO 2 The thickness of the layer is 8nm (wherein, it needs to be explained that Si@SiO 2 Nanoparticles represent Si as the core and SiO as the cladding layer 2 , the following examples and comparative examples represent the same meaning).

[0126] The above Si@SiO 2 Nanoparticles, graphite with a median particle size of 10 μm, polyacrylic acid and binder (including aluminum dihydrogen phosphate) are dispersed in a mixed solvent of water and ethanol, wherein the water: ethanol weight ratio is 10:90, graphite, polyacrylic acid and The weight ratio of the binder is 2:3, stir evenly, and then dry to obtain the precursor.

[0127] Mix the above precursor powder with glucose with a particle size of 5 μm in a mass ratio of 20:80, then mix with VC, the mixing parameters are frequency 25HZ,...

Embodiment 2

[0132] Put nano-Ge particles with a median particle size of 100nm in a heat treatment furnace, pass air into it, heat up to 500 degrees, and keep it for 30 minutes to obtain Ge@GeO with an oxide layer 2 Nanoparticles, GeO 2 The thickness of the layer is 15 nm.

[0133] Put the above Ge@GeO 2Nanoparticles, graphite with a median particle size of 1 μm, polyvinyl chloride, and a binder (the binder includes aluminum dihydrogen phosphate) are dispersed in a mixed solvent of water and ethanol, wherein the weight ratio of water: ethanol is 20:80, graphite The weight ratio of the polyvinyl chloride and the binder is 94:3:3, stir evenly, and then dry to obtain the precursor.

[0134] Mix the above precursor powder and phenolic resin with a particle size of 6 μm in a mass ratio of 20:20, then mix with VC, the mixing parameters are frequency 20HZ, time 70min, and then add it to the fusion machine, adjust the speed to 400rpm, and fuse 0.5h, then placed in a box-type furnace, fed with n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com