A kind of flame-retardant polymer polyol and its preparation method and application

A technology of flame-retardant polymers and polyols, applied in flame-retardant polyurethane materials, low-odor flame-retardant polymer polyols and its preparation field, can solve the problems of reduced mechanical properties of polyurethane materials, and achieve low production costs, The effect of less residue and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

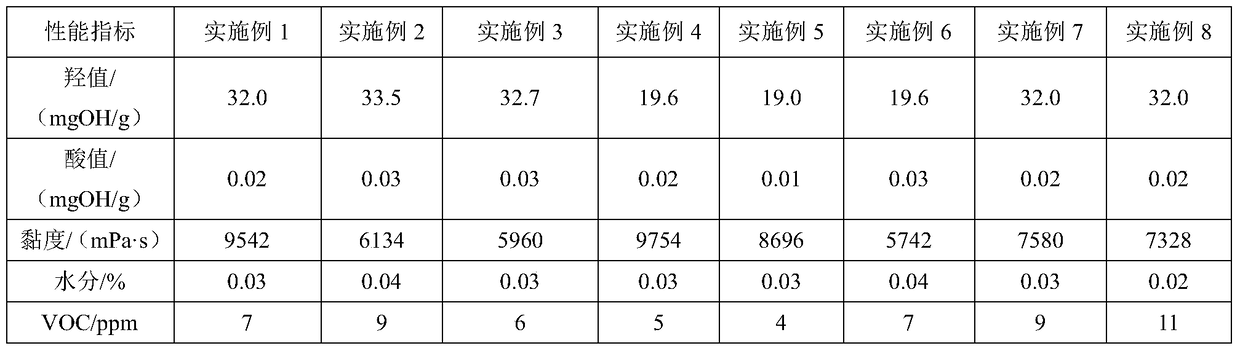

Embodiment 1

[0046] In a reactor equipped with a thermometer, a temperature controller, a condenser, a feeder and an ultraviolet photoinitiator, add 1320 g of propylene oxide and ethylene oxide copolymerization with glycerin as an initiator and a hydroxyl value of 56 mg KOH / g Wanol F3156, heated to 80°C; 1500g of dimethyl vinylphosphonate, 12.5g of azobisisobutyronitrile, 14.5g of dodecyl mercaptan, and 800g of Wanol F3156 were added to the feeder; Slowly add to the reactor, keeping the temperature at 80°C~85°C during the period. After the addition is complete, after 10 hours of reaction, add 3.2g of 2,4,6-trimethylbenzoyldiphenylphosphine oxide, stir for 1 hour, and turn on The photoinitiator was used for 12 minutes, and the line power was 200W to obtain a white flame-retardant polymer polyol. The viscosity measured by a viscometer was 9542 mPa·s (25° C.).

Embodiment 2

[0048] In a reactor equipped with a thermometer, a temperature controller, a condenser, a feeder and an ultraviolet photoinitiator, add 1320 g of propylene oxide and ethylene oxide copolymerization with glycerin as an initiator and a hydroxyl value of 56 mg KOH / g Wanol F3156, heated to 100°C; Add 1600g of dimethyl vinylphosphonate, 800g of 2,3-dibromopropene, 12.7g of azobisisobutyronitrile, 15.2g of dodecyl mercaptan, and 1200g of Wanol F3156 In the feeder; slowly add the material in the feeder to the reactor, keep the temperature at 100°C~105°C during the period, react for 10h after the addition, add 2,4,6-trimethylbenzoyl diphenylphosphine oxide After 3.3g, stir for 1 hour, turn on the photoinitiator for 10 minutes, and the line power is 200W to obtain a white flame-retardant polymer polyol. The viscosity is 6134mPa·s (25°C).

Embodiment 3

[0050] In the reactor equipped with thermometer, temperature controller, condenser, feeder and ultraviolet photoinitiator, add propylene oxide and ethylene oxide copolymer with glycerol as initiator and hydroxyl value of 56mg KOH / g Wanol F3156 1320g, heated to 100°C; 1000g of 2,3-dibromopropene, 12.9g of azobisisobutyronitrile, 14.5g of dodecyl mercaptan, and 200g of Wanol F3156 were added to the feeder; The material is slowly added into the reactor, and the temperature is kept at 120°C to 125°C during the period. After the addition is complete, it is reacted for 8 hours. After adding 3.0g of 2,4,6-trimethylbenzoyldiphenylphosphine oxide, stir for 1 hour and turn on The photoinitiator was used for 10 minutes, and the line power was 200W to obtain a white flame-retardant polymer polyol. The viscosity is 5960mPa·s (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com