Preparation method of dry quenching furnace chute corbel brick

A CDQ furnace and corbel technology, applied in the field of refractory materials, can solve the problems of high dependence on CDQ coke supply, huge impact on blast furnace production, and inability to meet the use requirements, achieving good temperature control effects, good molding effects, Combined Phase Stabilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a CDQ furnace chute corbel pillar brick is specifically carried out according to the following steps:

[0034] Step S1, mixing ingredients:

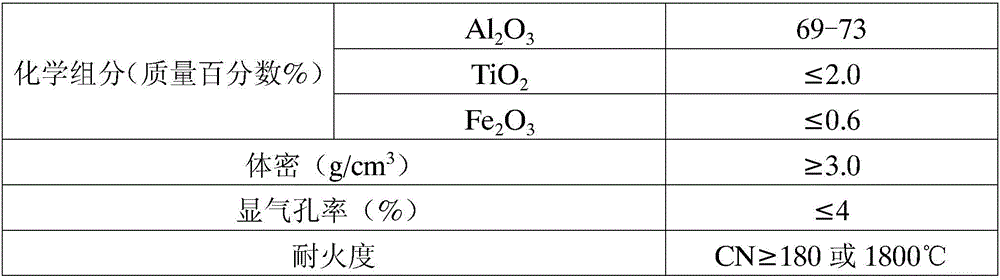

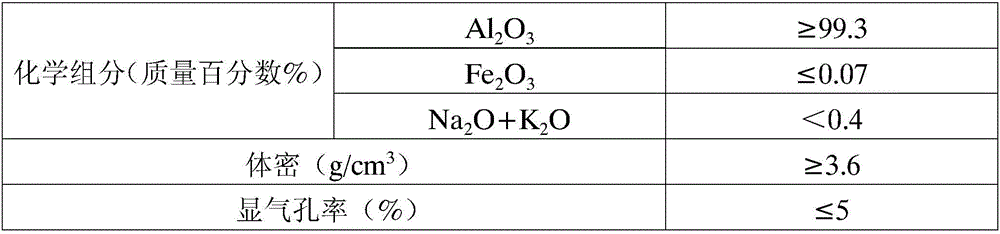

[0035] 1) Ingredients according to the composition (mass percentage) of corbel pillar bricks: 46% andalusite, 29% fused mullite, 5% kaolin fine powder, α-Al 2 o 3 5% fine powder, 7% high alumina bauxite, 8% platy corundum;

[0036] 2) Separately mix the granules and fine powder in the composition ingredients, put the granules into a forced planetary mixer, and then add the well-mixed fine powder and stir together to ensure that the stirring is sufficient and even;

[0037] Step S2, mixing and milling: add 3% aluminum metaphosphate composite solution to the material stirred and mixed uniformly in step S1 to carry out wet rolling, wet rolling for 5 minutes, and mix and grind evenly;

[0038] Step S3, pressing and forming: after mixing and grinding, send it to the side of the 630t friction press through the ...

Embodiment 2

[0052] A method for preparing a CDQ furnace chute corbel pillar brick is specifically carried out according to the following steps:

[0053] Step S1, mixing ingredients:

[0054] 1) Ingredients according to the composition (mass percentage) of corbel pillar bricks: 47% andalusite, 28% fused mullite, 5.5% kaolin fine powder, α-Al 2 o 3 Micro powder 4.5%, high alumina bauxite 7%, tabular corundum 8%;

[0055] 2) Separately mix the granules and fine powder in the composition ingredients, put the granules into a forced planetary mixer, and then add the well-mixed fine powder and stir together to ensure that the stirring is sufficient and even;

[0056] Step S2, mixing and milling: add 3% aluminum metaphosphate composite liquid to the material stirred and mixed uniformly in step S1, and carry out wet rolling, wet rolling for 10 minutes, and mix and grind evenly;

[0057] Step S3, pressing and forming: after mixing and grinding, send it to the side of the 630t friction press thro...

Embodiment 3

[0071] A method for preparing a CDQ furnace chute corbel pillar brick is specifically carried out according to the following steps:

[0072] Step S1, mixing ingredients:

[0073] 1) Ingredients according to the composition (mass percentage) of corbel pillar bricks: 45% andalusite, 31% fused mullite, 5% kaolin fine powder, α-Al 2 o 3 5% fine powder, 6.5% high alumina bauxite, 7.5% tabular corundum;

[0074] 2) Separately mix the granules and fine powder in the composition ingredients, put the granules into a forced planetary mixer, and then add the well-mixed fine powder and stir together to ensure that the stirring is sufficient and even;

[0075] Step S2, mixing and milling: add 3% aluminum metaphosphate composite liquid to the material stirred and mixed uniformly in step S1 to carry out wet rolling, wet rolling for 8 minutes, and mix and grind evenly;

[0076] Step S3, pressing and forming: after mixing and grinding, send it to the side of the 630t friction press through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com