An intelligent integrated pharmaceutical dust-free conveying system

A conveying system and intelligent technology, applied in transportation and packaging, loading/unloading, grain handling, etc., can solve the problems that restrict the development of large-scale and intensive production of enterprises, secondary pollution and infection, and labor-intensive workers. High level of automation, labor saving, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

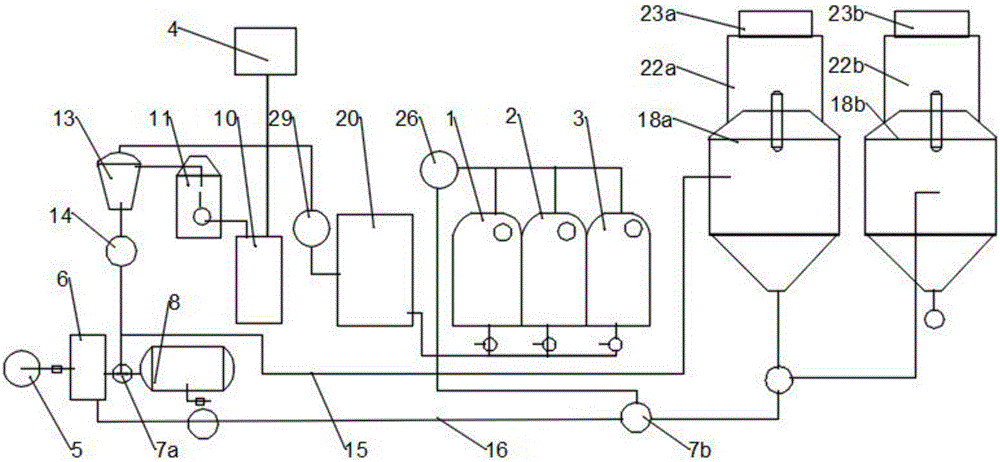

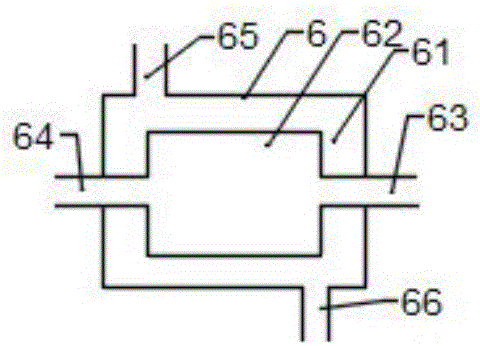

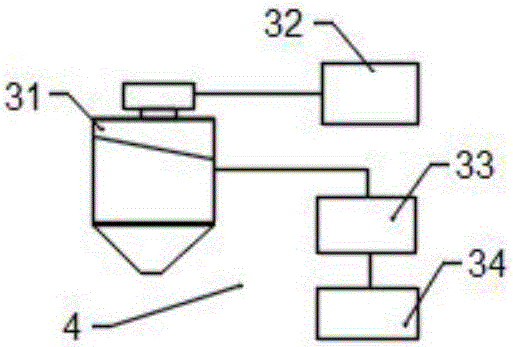

[0008] In order to have a further understanding of the present invention, the principles and features of the present invention will be described below in conjunction with the accompanying drawings, such as Figure 1-4 As shown, in this system, the control device, raw material loading device, gas generator, sterilization and separation device, cleaning device, etc., the control device includes a manual control device and an intelligent automatic control device, and the manual control device includes a corresponding operation control platform , Operation control cabinet.

[0009] Its raw material loading device is arranged on one side of the manual control device. The raw material loading device includes a raw material storage 10, a material lifting conveyor 11, a control box, and a feed hopper 13. The outlet of the raw material storage 10 passes through The pipeline is connected to the inlet end of the material lifting conveyor 11 , and the outlet end of the material lifting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com