Back-flushing filtration system and filtration method for cutting fluid

A filtration system and cutting fluid technology, applied in fixed filter element filters, filtration circuits, filtration separation, etc., can solve the problems of no filter element self-cleaning function, the filtration efficiency needs to be improved, and the high precision is not satisfied, and the structure is simple, The effect of long service life and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

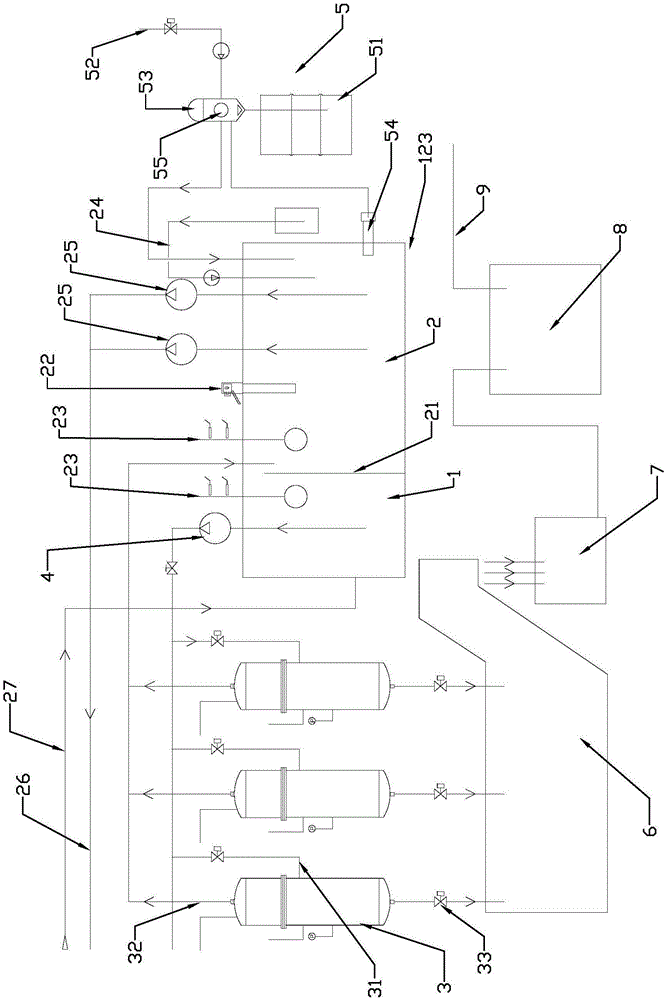

[0032] like Figure 1-3 As shown, in this embodiment, the recoil type cutting fluid filtration system includes a liquid storage box 123 with a dirty liquid chamber 1 and a clean liquid chamber 2, and a belt scraper 22 and The liquid level monitor 23 located in the dirty liquid chamber 1 and the clean liquid chamber 2, and the outside of the liquid storage box 123 is provided with a sterilizing and dosing mechanism 24 connected with the clean liquid chamber 2, the dirty liquid inlet of the dirty liquid chamber 1 is connected to the The dirty liquid return pipe 27 of the machine tool is connected, the clean liquid outlet of the clean liquid chamber 2 is connected with the clean liquid supply pipe 26 through the liquid supply pump 25, and at least one filter core 34 is provided on one side of the liquid storage box 123. Rush self-cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com