Biocompatible bone graft and preparation method thereof

A technology of biocompatibility and bone graft, applied in the field of biocompatible bone graft and its preparation, can solve the problem of lack of ability to promote cell adhesion and regeneration, lack of cartilage regeneration ability, difficulty in applying bone graft, etc. problems, to achieve the effect of facilitating the adhesion and regeneration of bone cells, the adhesion of bone cells, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

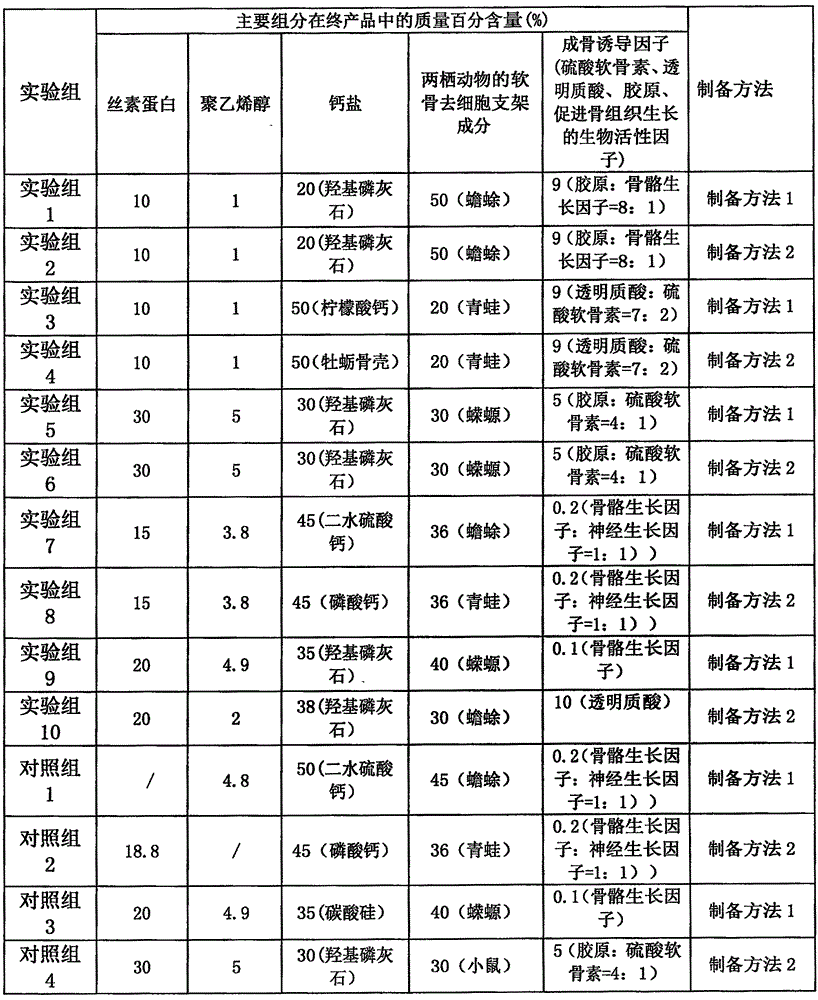

[0022] Example 1 Preparation of Biocompatible Bone Graft with Regenerative Performance and Elastic Strength

[0023] Preparation method 1: According to the composition of each experimental group and control group of biocompatible bone grafts in Table 1, each component was weighed, and the amphibian cartilage decellularized scaffold was crushed, and calcium salt, silk fibroin and osteogenic The inducing factor is mixed evenly, and polyvinyl alcohol ethanol solution is added, and mixed evenly to form a uniform semi-solid, which is placed in a metal mold for drying and molding to form a three-dimensional tubular bone graft with a hollow channel, and is sterilized by gamma-ray irradiation.

[0024] Preparation method 2: According to the composition of each experimental group and control group of biocompatible bone grafts in Table 1, each component was weighed, and the amphibian cartilage decellularized scaffold was crushed, mixed with calcium salt and silk fibroin, Add polyvinyl a...

Embodiment 2

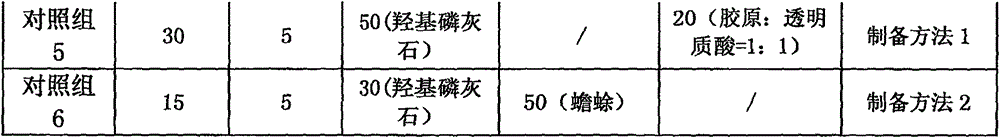

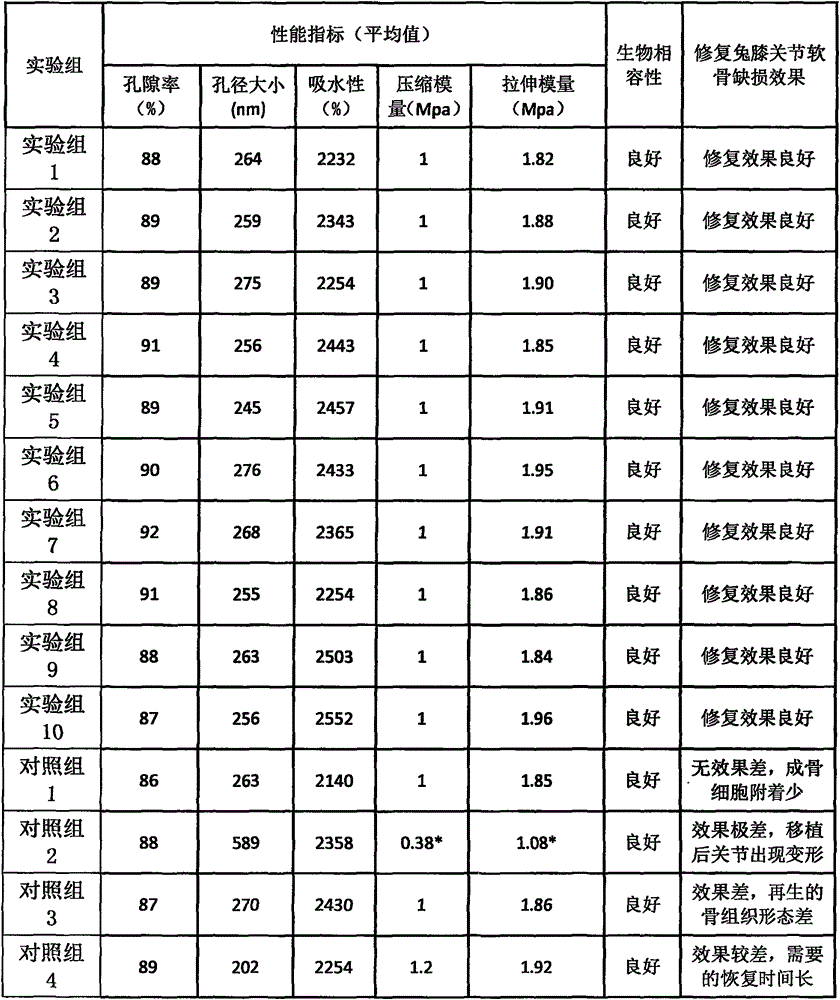

[0029] Performance testing and application effect of embodiment 2 biocompatible bone graft

[0030] (1) Performance testing of bone grafts in each group

[0031] Observation of surface pore size: whether the porosity and pore size of the surface of the biocompatible bone grafts in each group were uniform under light microscope and scanning electron microscope observation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com