Calcium-plastic high-intensity corrugated paper and preparation method thereof

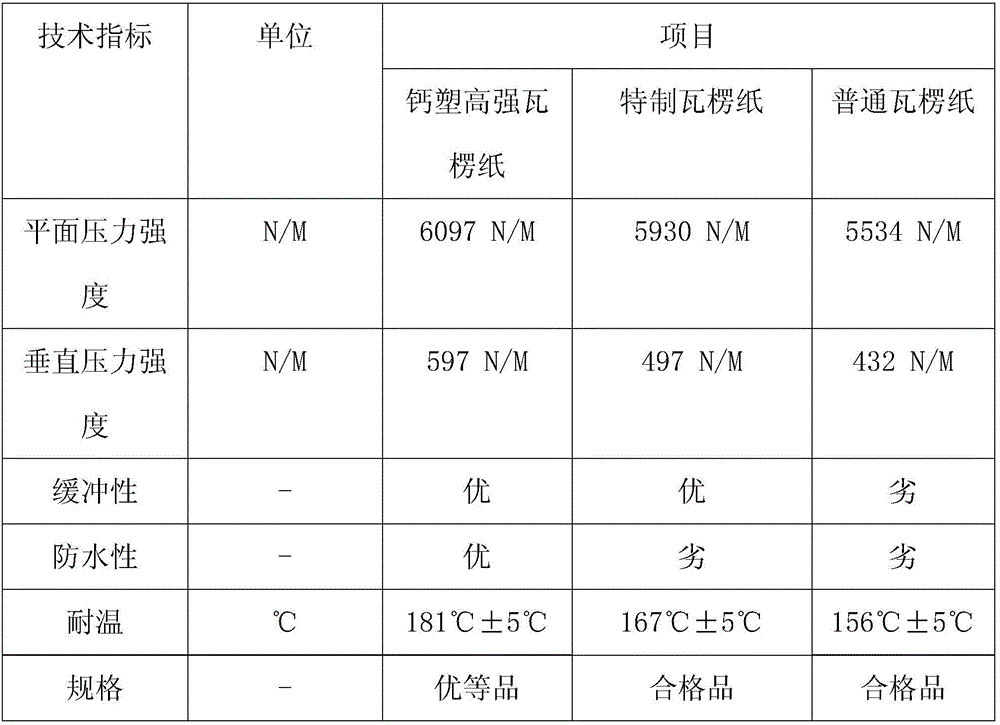

A corrugated paper and high-strength technology, applied in the field of calcium-plastic high-strength corrugated paper and its preparation, can solve the problems of uneven thickness, poor buffer performance, poor waterproof performance, etc., and achieve the effects of uniform thickness, good buffer performance, and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A calcium-plastic high-strength corrugated paper, made of a corrugated layer and a plastic layer, the corrugated layer includes the following raw materials in parts by weight: 400 parts of waste newspaper, 80 parts of straw, 80 parts of bark, 100 parts of modified cornstarch, 50 parts of graphene, 60 parts of borax powder, 40 parts of sodium bentonite, 30 parts of potassium permanganate, 21 parts of aluminum hydroxide, 20 parts of sodium carbonate, 11 parts of ammonium persulfate and 20 parts of calcium carbonate, the plastic layer includes The raw materials are as follows in parts by weight: 40 parts of polyvinyl chloride, 21 parts of phenolic resin, 11 parts of denatured alcohol, 3 parts of toluene, 13 parts of titanium dioxide and 14 parts of N,N-dimethylbenzylamine.

[0023] A preparation method of calcium-plastic high-strength corrugated paper, comprising the following steps:

[0024] 1) Take 400 copies of waste newspapers and crush them through a paper shredder, t...

Embodiment 2

[0034] A calcium-plastic high-strength corrugated paper, made of a corrugated layer and a plastic layer, the corrugated layer includes the following raw materials in parts by weight: 200 parts of waste newspaper, 110 parts of straw, 120 parts of bark, 160 parts of modified cornstarch, 70 parts of graphene, 80 parts of borax powder, 56 parts of sodium bentonite, 36 parts of potassium permanganate, 35 parts of aluminum hydroxide, 30 parts of sodium carbonate, 27 parts of ammonium persulfate and 30 parts of calcium carbonate, the plastic layer includes The raw materials are as follows in parts by weight: 60 parts of polyvinyl chloride, 27 parts of phenolic resin, 17 parts of denatured alcohol, 7 parts of toluene, 19 parts of titanium dioxide and 22 parts of N,N-dimethylbenzylamine.

[0035] A preparation method of calcium-plastic high-strength corrugated paper, comprising the following steps:

[0036] 1) Take 200 copies of waste newspapers and crush them through a paper shredder,...

Embodiment 3

[0046] A calcium-plastic high-strength corrugated paper, made of a corrugated layer and a plastic layer, the corrugated layer includes the following raw materials in parts by weight: 300 parts of waste newspaper, 95 parts of straw, 100 parts of bark, 130 parts of modified cornstarch, 60 parts of graphene, 70 parts of borax powder, 48 parts of sodium bentonite, 38 parts of potassium permanganate, 28 parts of aluminum hydroxide, 25 parts of sodium carbonate, 19 parts of ammonium persulfate and 25 parts of calcium carbonate. The plastic layer includes The raw materials are as follows in parts by weight: 50 parts of polyvinyl chloride, 24 parts of phenolic resin, 14 parts of denatured alcohol, 5 parts of toluene, 16 parts of titanium dioxide and 18 parts of N,N-dimethylbenzylamine.

[0047] A preparation method of calcium-plastic high-strength corrugated paper, comprising the following steps:

[0048] 1) Take 300 copies of waste newspapers and crush them through a paper shredder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com