A rolling method of ultra-high strength aluminum alloy plate

An aluminum alloy plate and ultra-high-strength technology, which is applied in the field of aluminum alloy materials, can solve problems such as reduction, durability of aluminum alloy materials, and damage tolerance that cannot be improved simultaneously, and achieve the elimination of dendrite segregation, increase in microhardness, and increase intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

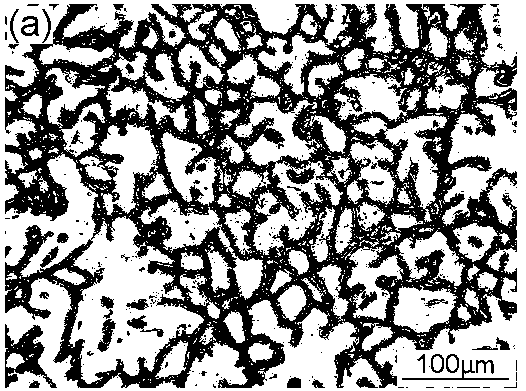

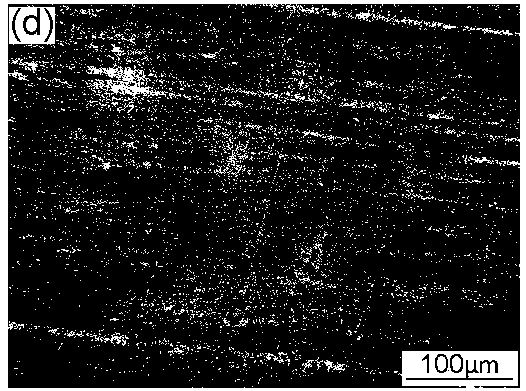

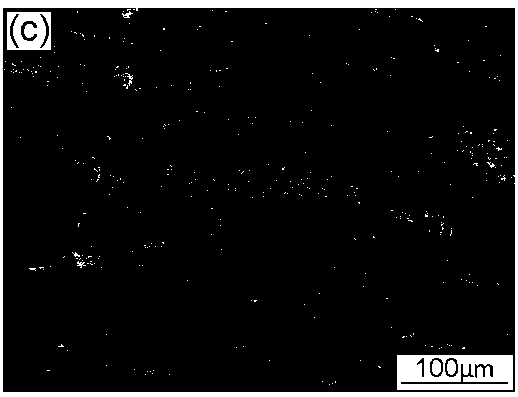

Image

Examples

Embodiment 1

[0025] The rolling method of the ultra-high-strength aluminum alloy plate of the present invention comprises the following steps:

[0026] A. Homogenize and anneal the Al-Cu-Mg alloy billet after refining at 450°C for 24 hours;

[0027] B. Control the temperature of the Al-Cu-Mg alloy billet after annealing at 360°C. After the temperature inside and outside of the Al-Cu-Mg alloy billet is uniform, perform a single-pass 2% hot rolling pre-deformation, roll rolling The line speed is 0.4m / min, continue to control the temperature of the Al-Cu-Mg alloy billet to 360°C, and then carry out a single-pass 60% large-reduction rolling deformation, and the rolling line speed is 0.4m / min. min, the thick slab is obtained by rolling, and the thick slab is water-cooled or air-cooled;

[0028] C. The cooled thick slab is subjected to solution treatment at 450°C for 0.5h, and then water quenched;

[0029] D. Pre-aging the thick slab after water quenching at 150°C for 6 hours, and then air coo...

Embodiment 2

[0034] The rolling method of the ultra-high-strength aluminum alloy plate of the present invention comprises the following steps:

[0035] A. Homogenize and anneal the Al-Cu-Mg alloy billet after refining at 460°C for 28 hours;

[0036] B. Control the temperature of the Al-Cu-Mg alloy billet after annealing at 380°C. After the temperature inside and outside of the Al-Cu-Mg alloy billet is uniform, perform a single-pass 3% hot rolling pre-deformation, roll rolling The line speed is 0.5m / min, continue to control the temperature of the Al-Cu-Mg alloy billet to 380°C, and then carry out a single-pass 62% large reduction rolling deformation, and the roll rolling line speed is 0.5m / min. min, the thick slab is obtained by rolling, and the thick slab is water-cooled or air-cooled;

[0037] C. The cooled thick slab is subjected to solution treatment at 480°C for 1 hour, and then water quenched;

[0038] D. Pre-aging the thick slab after water quenching at 180°C for 6 hours, and then ...

Embodiment 3

[0043] The rolling method of the ultra-high-strength aluminum alloy plate of the present invention comprises the following steps:

[0044] A. Homogenize and anneal the Al-Cu-Mg alloy billet after refining at 500°C for 32 hours;

[0045] B. Control the temperature of the Al-Cu-Mg alloy billet after annealing at 400°C. After the temperature inside and outside of the Al-Cu-Mg alloy billet is uniform, perform a single-pass 4% hot rolling pre-deformation, roll rolling The line speed is 0.6m / min, continue to control the temperature of the Al-Cu-Mg alloy billet to 400°C, and then carry out a single pass of 65% large reduction rolling deformation, and the roll rolling line speed is 0.6m / min. min, the thick slab is obtained by rolling, and the thick slab is water-cooled or air-cooled;

[0046] C. The cooled thick slab is subjected to solution treatment at 500°C for 1.5h, and then water quenched;

[0047] D. Pre-aging the thick slab after water quenching at 200°C for 6 hours, the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com