Liquid pipeline dredging agent and preparation method thereof

A technology for liquid pipelines and dredging agents, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of secondary blockage of pipeline dredging agents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

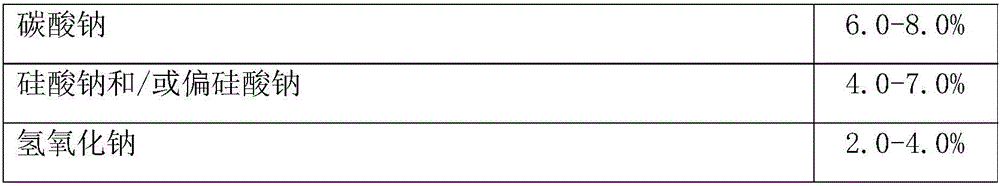

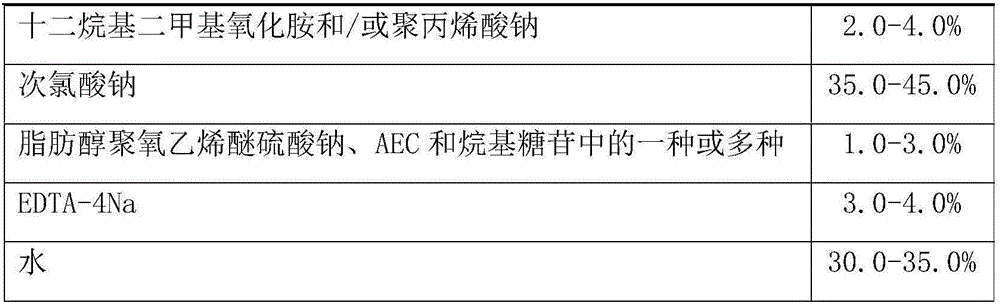

Method used

Image

Examples

Embodiment 1

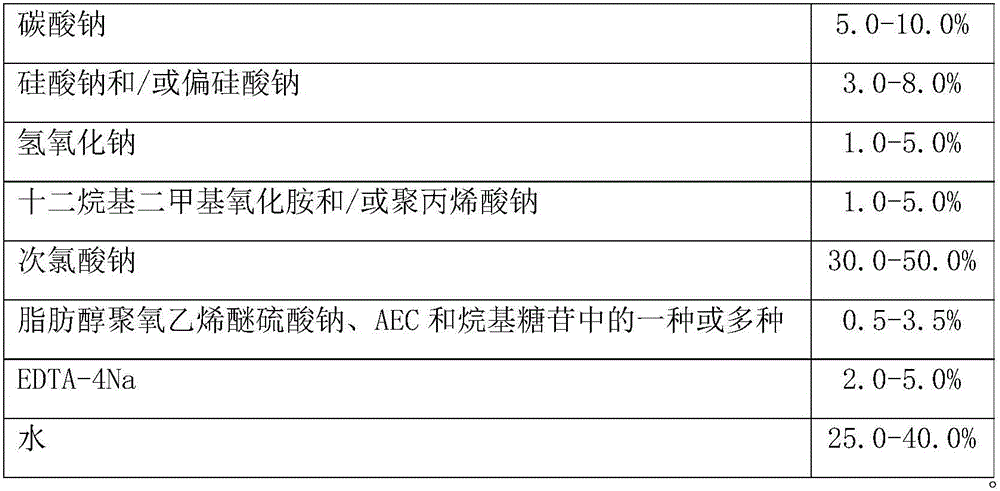

[0014] A liquid pipe dredging agent, the liquid pipe dredging agent is composed of the following components by weight percentage:

[0015] raw material formula,% single component action Sodium carbonate 8.0 clean Sodium silicate 5.0 corrosion inhibition sodium hydroxide 4.0 dredging, decontamination dodecyl dimethyl amine oxide 4.0 regulate fluidity sodium hypochlorite 35 Dredge, sterilize Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 2.0 penetration EDTA-4Na 4.0 Chelating agent water 38.0 solvent

[0016] The preparation method of the above-mentioned liquid pipeline dredging agent, the method comprises the following steps: first add water into the batching tank, start stirring, mix sodium hydroxide, sodium carbonate, sodium silicate, lauryl dimethyl amine oxide, Add fatty alcohol polyoxyethylene ether sodium sulfate and EDTA-4Na into the batching tank, stir evenly, and finally add sodium hypo...

Embodiment 2

[0018] A liquid pipe dredging agent, the liquid pipe dredging agent is composed of the following components by weight percentage:

[0019] raw material formula,% single component action Sodium carbonate 6.0 clean Sodium metasilicate 6.0 corrosion inhibition sodium hydroxide 5.0 dredging, decontamination Sodium polyacrylate 3.0 regulate fluidity sodium hypochlorite 40 Dredge, sterilize AEC 3.0 penetration EDTA-4Na 4.0 Chelating agent water 33.0 solvent

[0020] The preparation method of the above-mentioned liquid pipeline dredging agent, the method comprises the following steps: first add water into the batching tank, start stirring, and mix sodium hydroxide, sodium carbonate, sodium metasilicate, sodium polyacrylate, AEC, EDTA-4Na Add to the batching tank, stir evenly, and finally add sodium hypochlorite to the batching tank, stir evenly, settle for 24 hours and filter.

Embodiment 3

[0022] A liquid pipe dredging agent, the liquid pipe dredging agent is composed of the following components by weight percentage:

[0023] raw material formula,% single component action Sodium carbonate 8.0 clean Sodium silicate 5.0 corrosion inhibition Sodium metasilicate 1.0 corrosion inhibition sodium hydroxide 4.0 dredging, decontamination dodecyl dimethyl amine oxide 4.0 regulate fluidity Sodium polyacrylate 1.0 regulate fluidity sodium hypochlorite 40 Dredge, sterilize Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 2.0 penetration AEC 1.0 penetration EDTA-4Na 4.0 Chelating agent water 30 solvent

[0024] The preparation method of the above-mentioned liquid pipeline dredging agent, the method comprises the following steps: first add water into the batching tank, start stirring, mix sodium hydroxide, sodium carbonate, sodium metasilicate, sodium silicate, dodecyl diac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com