Nano-solution for decompression and injection augmentation of ultra-low permeability oil reservoir water-flooding development and preparation method of nano-solution

An ultra-low permeability, oil reservoir technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as weakening the effect of pressure reduction and injection, increasing operational complexity and product price, and easy loss of nanomaterials. , to achieve the effect of facilitating large-scale construction, improving development effect and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

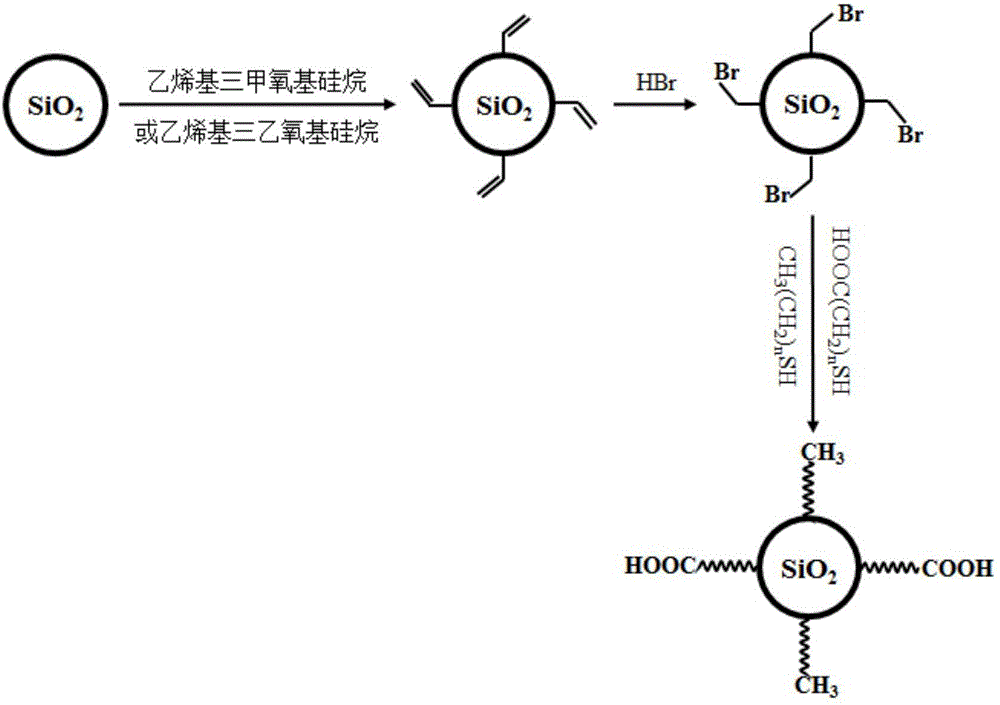

[0028] Such as figure 1 As shown, the preparation of double-group modified nano-silica particles:

[0029] Step 1, 4g primary particle size 7nm, specific surface area 200m 2 Add / g of nano-silica and 100mL of absolute ethanol into a three-necked flask, stir for 20min, add 4g of vinyltriethoxysilane, adjust the temperature of the oil bath to 70°C, and react under nitrogen protection for 4h; The liquid was separated by centrifugation or vacuum filtration, and the precipitate or filter cake was washed 4 times with absolute ethanol, and vacuum-dried at 60°C for 24 hours to obtain a powdery solid.

[0030] Step 2, disperse the solid powder obtained in step 1 in 100mL dimethylformamide, under nitrogen protection, add 0.1mol HBr solution, heat to 50°C, stir for 4 hours, cool to room temperature, and centrifuge the resulting mixture Separation or separation by vacuum filtration, washing the precipitate or filter cake 4 times with dimethylformamide, and vacuum drying at 60° C. for 24...

Embodiment 2

[0033] Such as figure 1 As shown, the preparation of double-group modified nano-silica particles:

[0034] Step 1, 5g primary particle diameter 7nm, specific surface area 250m 2 Add / g of nano-silica and 150mL of toluene into a three-necked flask, stir for 10min, add 5g of vinyltrimethoxysilane, adjust the temperature of the oil bath to 70°C, and react under nitrogen protection for 5h; centrifuge the fully reacted dispersion Alternatively, separate by vacuum filtration, wash the precipitate or filter cake four times with absolute ethanol, and dry under vacuum at 60° C. for 24 hours to obtain a powdery solid.

[0035] Step 2: Disperse the solid powder obtained in Step 1 in 100 mL of dimethylformamide, protect it under nitrogen, add a solution containing 0.1 mol of HBr, heat to 50°C, stir for 4 hours, cool to room temperature, and dissolve the resulting mixture Separation by centrifugation or vacuum filtration, washing the precipitate or filter cake 4 times with dimethylformam...

Embodiment 3

[0038] Preparation of nano-fluid for pressure reduction and injection enhancement in ultra-low permeability reservoir water injection development:

[0039] Step 1: Weigh 1 g of the double-group-modified nano-silica particles prepared in Example 1, add it into 500 mL of water, stir evenly, and heat to 60-80° C.

[0040] Step 2, continue stirring, and add 1 mol / L NaOH aqueous solution dropwise until the double-group modified nano-silica particles are uniformly dispersed.

[0041] The particle size distribution of the double-group modified nano-silica particles in the nano-fluid for reducing pressure and increasing injection was measured by a laser particle size analyzer, and the particle size distribution of the double-group modified nano-silica particles ranged from 10 to 20 nm.

[0042] Such as figure 2 As shown, select the ultra-low permeability natural rock core with gas permeability of 1-5mD, saturate simulated oil (viscosity 5mPa·s, 25℃), and use simulated water (3%NaCl)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com