Degradable master batch for plastic films, method for preparing degradable master batch and application thereof

A technology for degrading masterbatches and plastic films, which is applied in the field of plastic films to achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

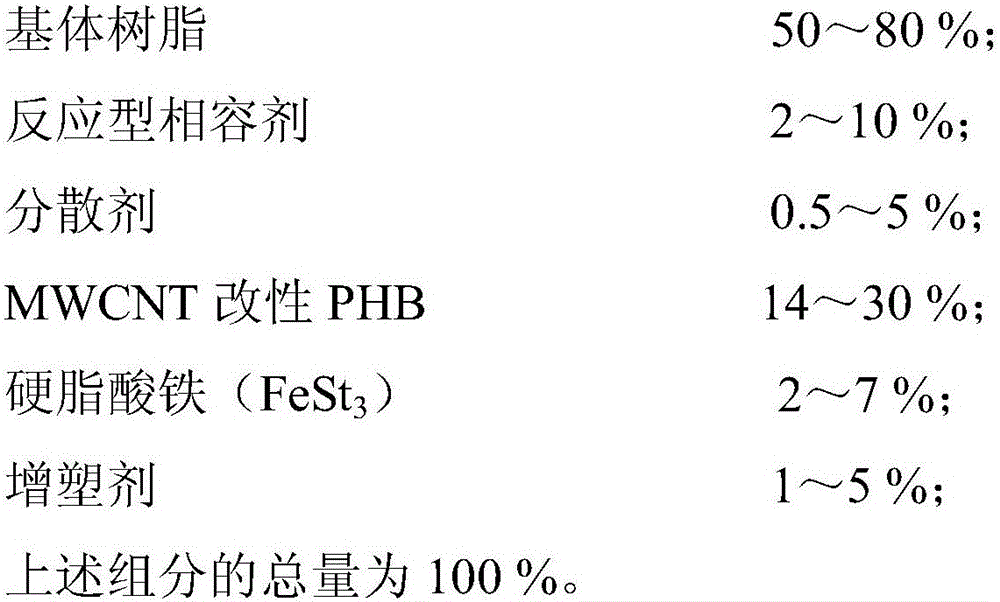

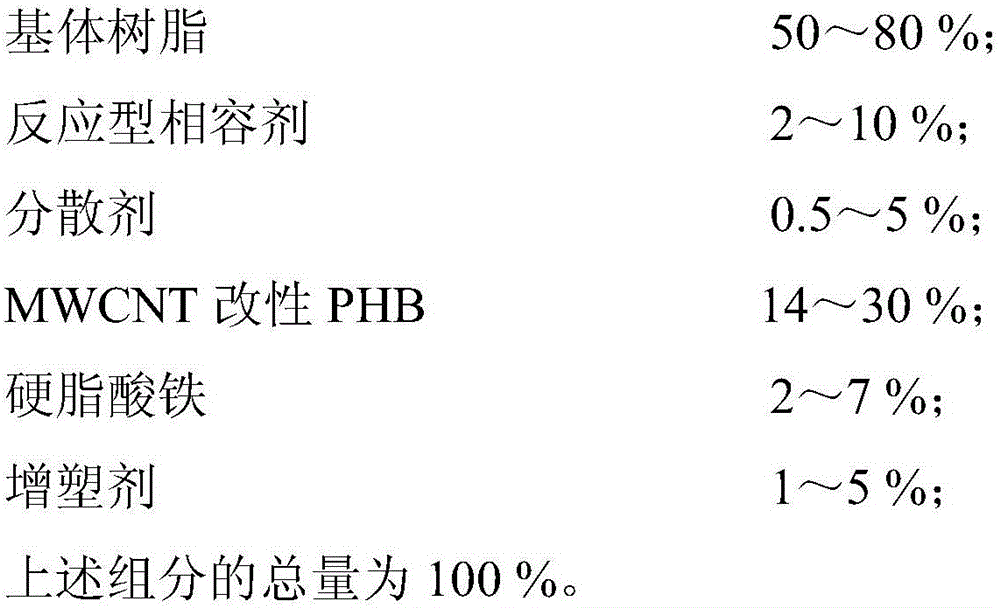

Method used

Image

Examples

Embodiment 1

[0026] (1) Treatment of MWCNT-modified PHB: The surface of multi-walled carbon nanotubes (MWCNT) was organically treated with a silane coupling agent. First, heat the absolute ethanol solution of the silane coupling agent to 55° C. in a water bath, stir evenly, add measured MWCNT, filter while hot after stirring, and obtain the modified MWCNT after drying. PHB and modified MWCNT were mixed in a mass ratio of 98:2, and then melt-extruded to obtain MWCNT-modified PHB.

[0027] (2) Low density polyethylene, Et-MAH-EA terpolymer, TAS-2A dispersant, MWCNT modified PHB, iron stearate, plasticizer (DOP) with 50:6:5:30: The masterbatch is prepared by mixing in a high-speed mixer for 30 minutes in a mass percentage ratio of 4:5, and then melting and blending in an internal mixer at 120-160°C, and discharging after mixing evenly.

[0028] (3) The plastic film prepared by adding 2% of the degradable masterbatch of the plastic film obtained in step (2) to the polyester has a degradation ...

Embodiment 2

[0030] (1) The treatment of MWCNT modified PHB is the same as in Example 1.

[0031] (2) A composition of linear low-density polyethylene and low-density polyethylene with a mass ratio of 1:1, anhydride-modified SEBS, TAS-2A dispersant, MWCNT-modified PHB, iron stearate, plasticizer (DOP ) with a mass percentage ratio of 80:2:1:14:2:1, mixed in a high-speed mixer for 30 minutes, then melted and blended in an internal mixer at 120-160°C, and discharged after mixing evenly. of the masterbatch.

[0032] (3) The plastic film prepared by adding the degradable masterbatch of plastic film obtained in step (2) to polyester at 2% has a degradation rate of 85% after being buried in soil for 10 days at room temperature.

Embodiment 3

[0034] (1) The treatment of MWCNT modified PHB is the same as in Example 1.

[0035] (2) The composition of low-density polyethylene and high-density polyethylene mixed at a mass ratio of 1:1, MAH-g-PS, TAS-2A dispersant, MWCNT modified PHB, iron stearate, plasticizer (DBP ) with a mass percentage ratio of 60:10:5:20:3:2, mixed in a high-speed mixer for 30 minutes, then melted and blended in an internal mixer at 120-160°C, and discharged after mixing evenly. of the masterbatch.

[0036] (3) Add the degradable masterbatch of plastic film obtained in step (2) to the plastic film prepared by adding 2% to polycarbonate, and the degradation rate after being buried in soil for 10 days at room temperature is 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com