Preparation method of photoresponsive anisotropic azo polymer/carbon tube composite film

A technology of azo polymer and carbon tube film, which is applied in the field of preparation of azo polymer/carbon tube composite film, can solve the problems of no self-support, complicated preparation process, etc., and achieves high conductivity, good repeatability, The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

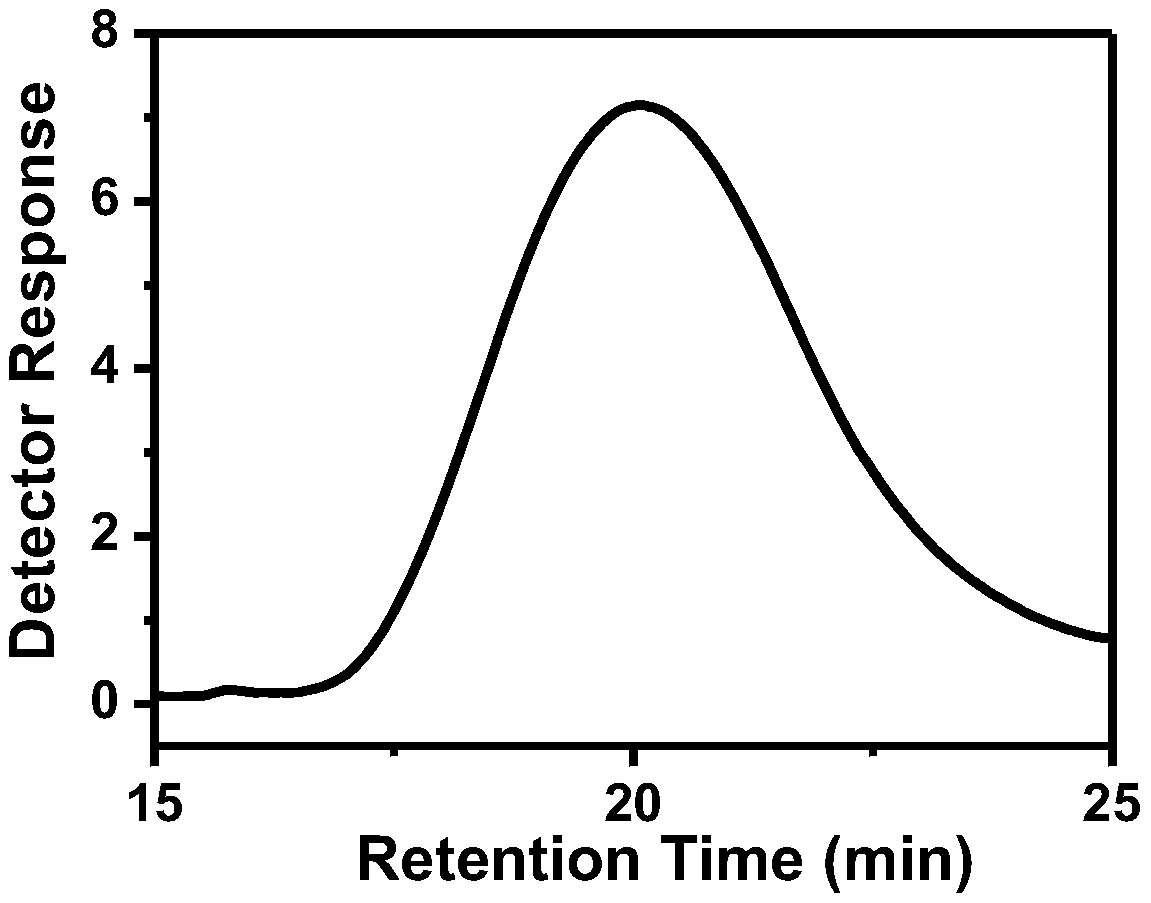

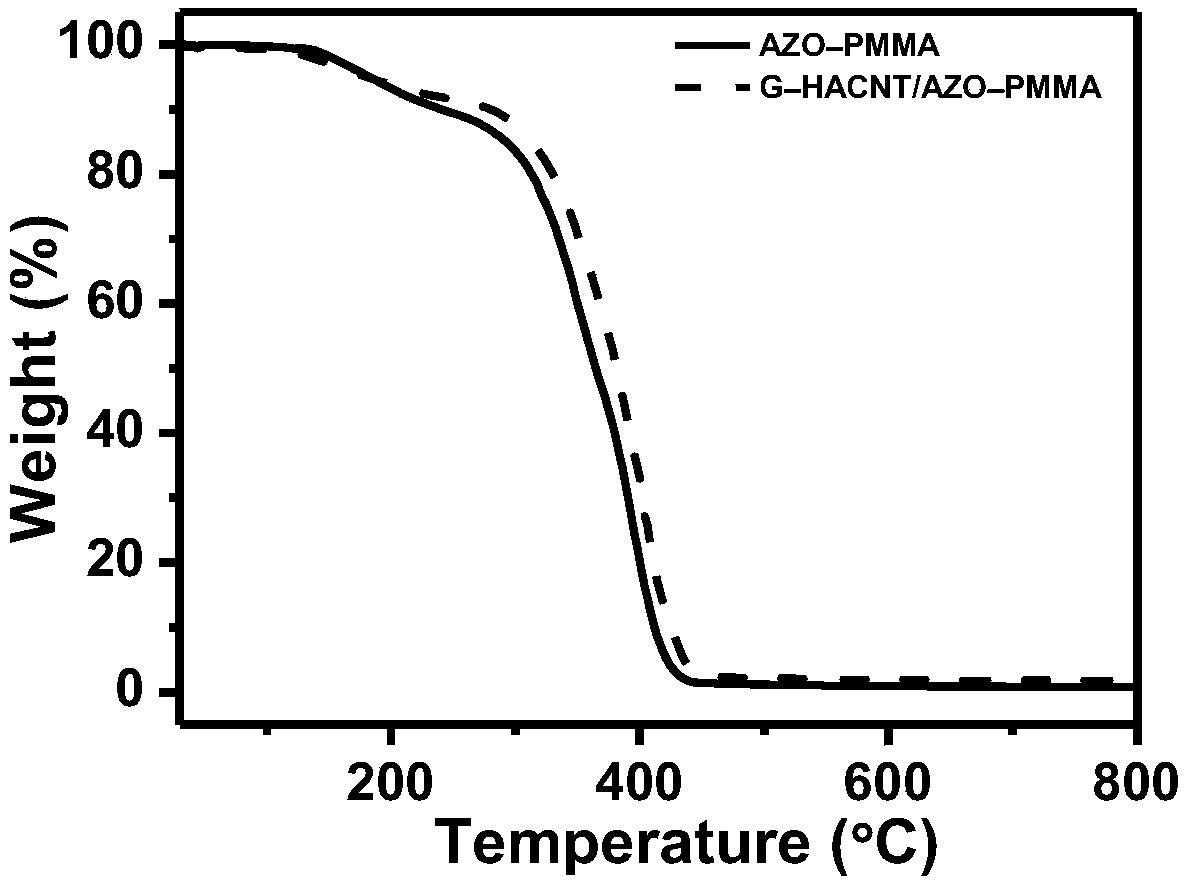

[0036] (1) Synthesis of azo polymers: polycondensation reaction between methyl methacrylate and azobenzene in a molar mass ratio of 1:5, the amount of initiator azobisisobutyronitrile (AIBN) added is methacrylic acid 1wt.% of the amount of methyl ester added. First, add methyl methacrylate and AIBN into a three-necked flask, and blow nitrogen at 25°C to remove the air in the system. Dissolve azobenzene in dichloromethane and slowly add it dropwise to the methyl methacrylate system, and the dropwise addition is completed within half an hour. The temperature was raised to 60° C. for the reaction, and the reaction was completed for 3 hours to obtain an azo polymer.

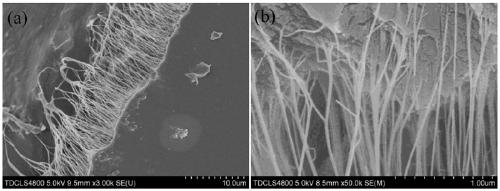

[0037] (2) Carbon tube membrane modification: Add 0.1mol / L p-phenylenediamine solution dropwise to 0.1mol / L HCl solution at a volume ratio of 1:1 to obtain an acidic p-phenylenediamine solution; at 0°C Under certain conditions, 0.1mol / L sodium nitrite solution is added dropwise into the acidic p-phenylenediamine so...

Embodiment 2

[0040] (1) Synthesis of azo polymers: polycondensation reaction between methyl methacrylate and azobenzene at a molar mass ratio of 1:15, the amount of initiator azobisisobutyronitrile (AIBN) added is methacrylic acid 3wt.% of the amount of methyl ester added. First, add methyl methacrylate and AIBN into a three-necked flask, and blow nitrogen at 25°C to remove the air in the system. Dissolve azobenzene in dichloromethane and slowly add it dropwise to the methyl methacrylate system, and the dropwise addition is completed within half an hour. The temperature was raised to 75° C. for the reaction, and the reaction was completed for 8 hours to obtain an azo polymer.

[0041] (2) Carbon tube membrane modification: Add 0.5mol / L p-phenylenediamine solution dropwise to 0.1mol / L HCl solution at a volume ratio of 1:1 to obtain an acidic p-phenylenediamine solution; at 0°C Under certain conditions, add 0.5 mol / L sodium nitrite dropwise into the acidic p-phenylenediamine solution to re...

Embodiment 3

[0052] (1) Synthesis of azo polymers: polycondensation reaction between methyl methacrylate and azobenzene in a ratio of 1:50 by molar mass ratio, and the addition amount of initiator azobisisobutyronitrile (AIBN) is methacrylic acid 2wt.% of the amount of methyl ester added. First, add methyl methacrylate and AIBN into a three-necked flask, and blow nitrogen at 25°C to remove the air in the system. Dissolve azobenzene in dichloromethane and slowly add it dropwise to the methyl methacrylate system, and the dropwise addition is completed within half an hour. The temperature was raised to 85° C. for reaction, and the reaction was completed in 12 hours to obtain an azo polymer.

[0053] (2) Carbon tube membrane modification: Add 0.8mol / L p-phenylenediamine solution dropwise to 0.1mol / L HCl solution at a volume ratio of 1:1 to obtain an acidic p-phenylenediamine solution; at 5°C Under certain conditions, add 0.8 mol / L sodium nitrite dropwise into the acidic p-phenylenediamine so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| burnout rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com