A formaldehyde-free water-based crosslinking agent and its preparation method and fabric finishing process

A cross-linking agent, water-based technology, applied in the field of non-iron, anti-wrinkle, formaldehyde-free cross-linking and anti-shrinkage of cellulose fabrics, it can solve the problems of decreased strength, poor non-iron effect, yellowing of fabrics, etc. Improved ironing performance and less powerful damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

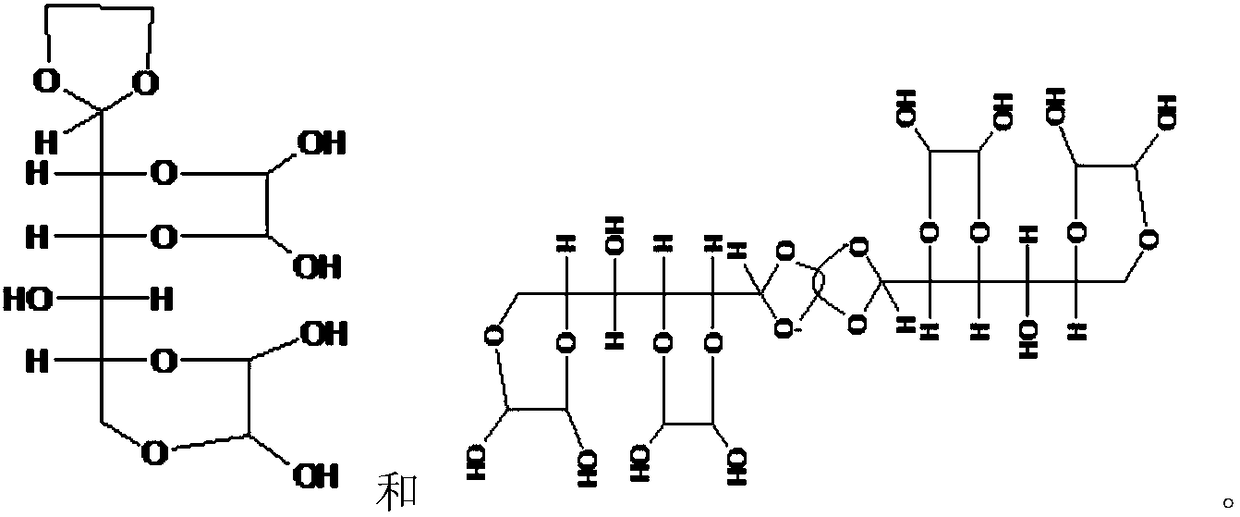

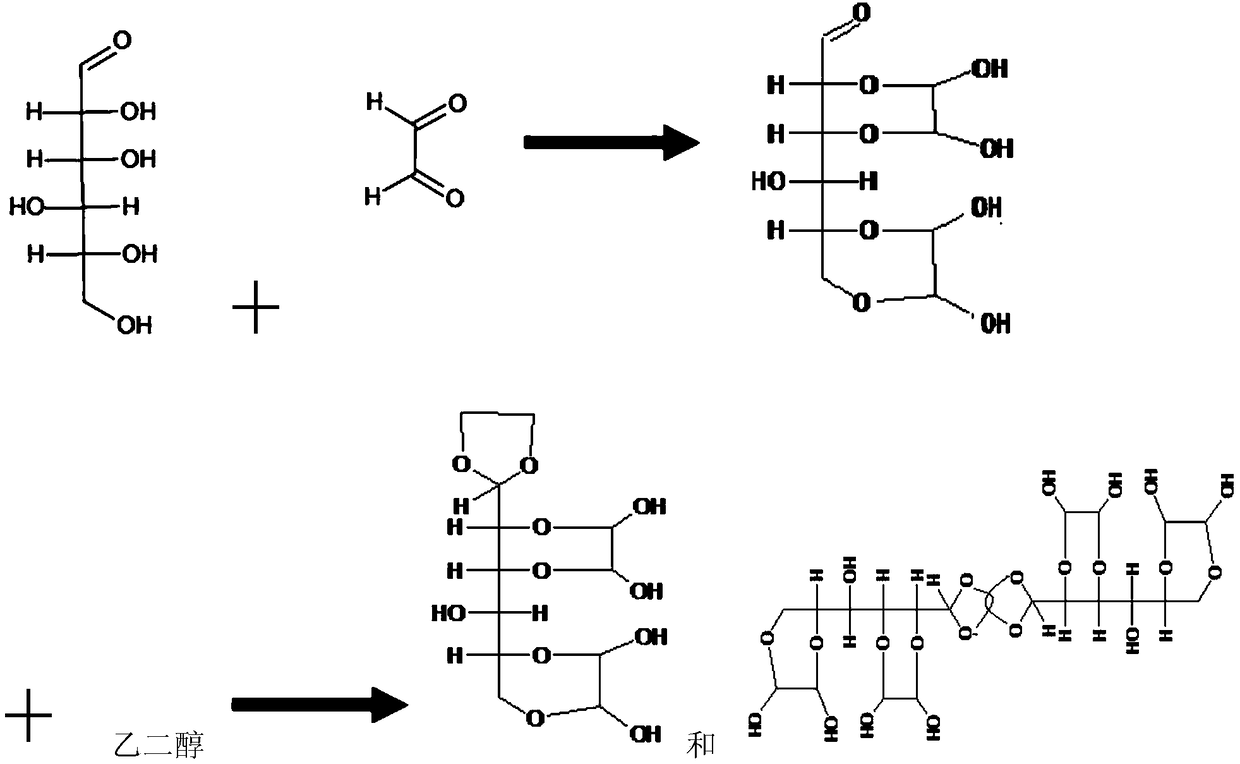

[0044] Preparation of crosslinker I:

[0045] After 180g glucose is dissolved in the technical grade glyoxal solution of 250g solute mass fraction 40%, add the concentrated hydrochloric acid catalyst of 0.8ml solute mass fraction 36.5% earlier, hemiacetalization reaction takes place under reflux for 1.5 hours, then control temperature at Distill and dehydrate at 102°C to 108°C until there is no distillate; then add 62g of ethylene glycol, slowly heat up to 110°C and keep warm until there is no distillate to acetalize the aldehyde group of ethylene glycol and glucose, and finally add sodium hydroxide Neutralize hydrochloric acid, cool and crystallize, and filter to obtain a mixture of various acetals and hemiacetals, that is, crosslinking agent I.

Embodiment 2

[0047] Preparation of crosslinker II:

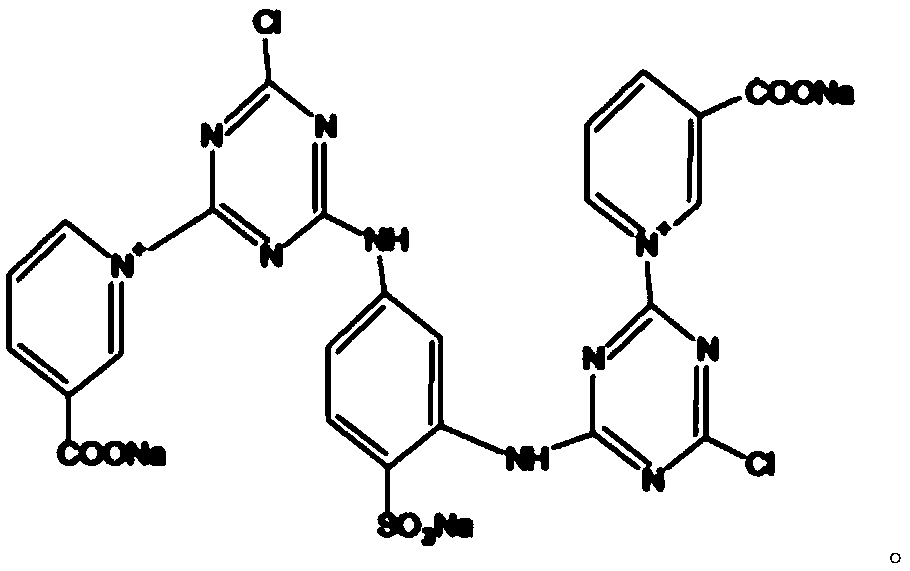

[0048] (1) Completely dissolve sodium 2,4-diaminobenzenesulfonate and sodium hydroxide in water, add tripolychlorazine and react at 35°C until the system is transparent,

[0049] The molar ratio of sodium 2,4-diaminobenzenesulfonate, sodium hydroxide and tripolychlorazine is 1:2:2;

[0050] (2) Add sodium hydroxide and 3-pyridinecarboxylic acid to the system obtained in step (1) and react at 47°C-50°C until the system is transparent again, and use a neutral buffer solution to adjust the pH of the system to 7, Obtain the aqueous solution of cross-linking agent II and store it below 50°C,

[0051] Wherein, the molar ratio of the added sodium hydroxide, 3-pyridinecarboxylic acid and the pure intermediate product in the system obtained in step (1) is 4:2:1.

[0052] Pretreatment of fiber fabrics:

[0053] The cotton fabric that has undergone desizing, scouring, bleaching, and mercerizing pretreatment is treated with liquid ammonia to obtain...

Embodiment 3

[0055] The cotton poplin cloth of above-mentioned pretreatment is soaked in the aqueous solution of cross-linking agent I prepared in embodiment 1 (wherein, cross-linking agent I 80g / L, catalyst ethylene glycol citrate triester 15g / L, pH value is 6), with a scraping rate of 78%, and then drying at 85°C for 60 seconds to make the moisture content of the fabric at this time 7%, then wrapping it with a plastic film at 30°C and stacking it for 3 hours, and finally washing it fully and putting it in Dry at 160°C,

[0056] During the experiment, the solution, the cloth surface during dipping, the cloth surface during the drying process at 85°C, the cloth surface during stacking, and the final cloth surface after drying at 160°C were tested many times. In the range of 6-7, samples were cooled and tested for moisture regain at room temperature (results are shown in Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com