Ganoderma lucidum bag-cultivation culture medium capable of increasing content of ganoderma lucidum polysaccharides and selenium in ganoderma lucidum

A technology of Ganoderma lucidum polysaccharides and Ganoderma lucidum bag, which is applied in cultivation, plant cultivation, mushroom cultivation, etc. It can solve the problems of small quantity of Ganoderma lucidum, inconvenient health food or pharmaceutical raw materials, low content of Ganoderma lucidum polysaccharides, etc., and achieve the effect that it is not easy to absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

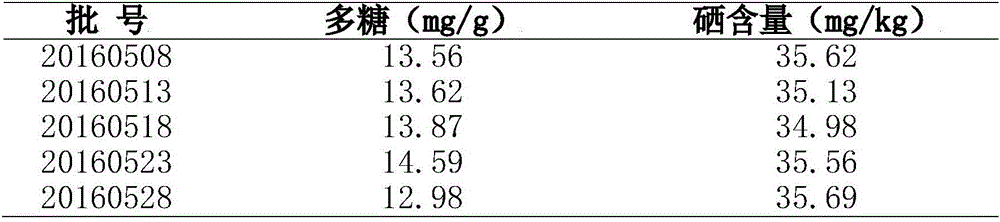

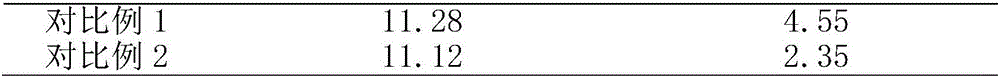

[0019] In order to verify the technical effect of the present invention, in 2016, use the technology of the present invention to produce 5 batches of products, and the method of each batch is as follows:

[0020] 1) Preparation of culture medium: It is made of the following raw materials in parts by weight: 75kg of sawdust, 20kg of wheat bran, 2kg of corn flour, 1kg of lime, 1kg of gypsum, and 1kg of sugar. The ratio of material to water is adjusted to 1:1.3 by using selenium-enriched nutrient solution -1.5;

[0021] 2) Mixing, bagging, sterilization, inoculation;

[0022] 3) Germination: After inoculation, put the bacteria into the greenhouse and control the temperature of the greenhouse at 26-28°C;

[0023] 4) Mushroom production: After the mycelium is full of bags, the ganoderma enters the period of production, and the temperature of the greenhouse is controlled to 26-28°C;

[0024] The selenium-enriched nutrient solution described in step 1) is obtained by the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com