Zero-valent iron type water purifying method based on electric field intensification and reactor

A zero-valent iron and reactor technology, applied in chemical instruments and methods, magnetic/electric field water/sewage treatment, water pollutants, etc., to achieve accelerated corrosion, avoid zero-valent iron passivation problems, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

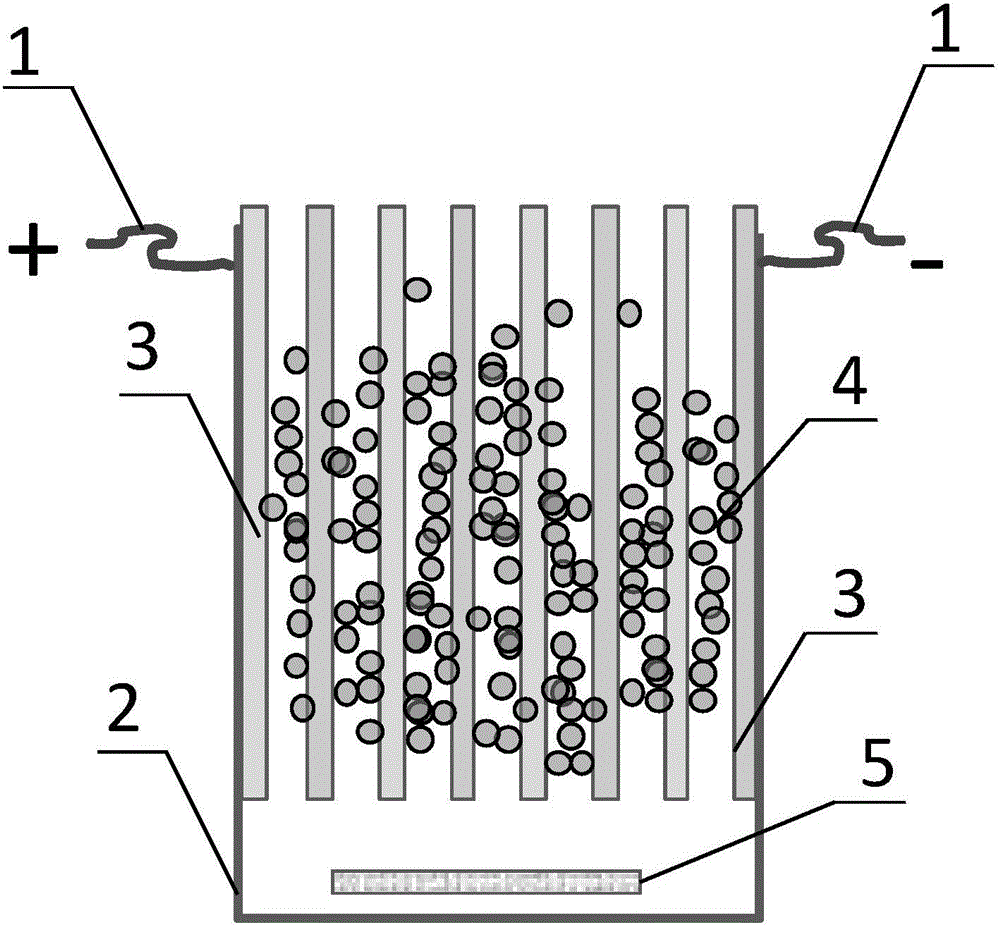

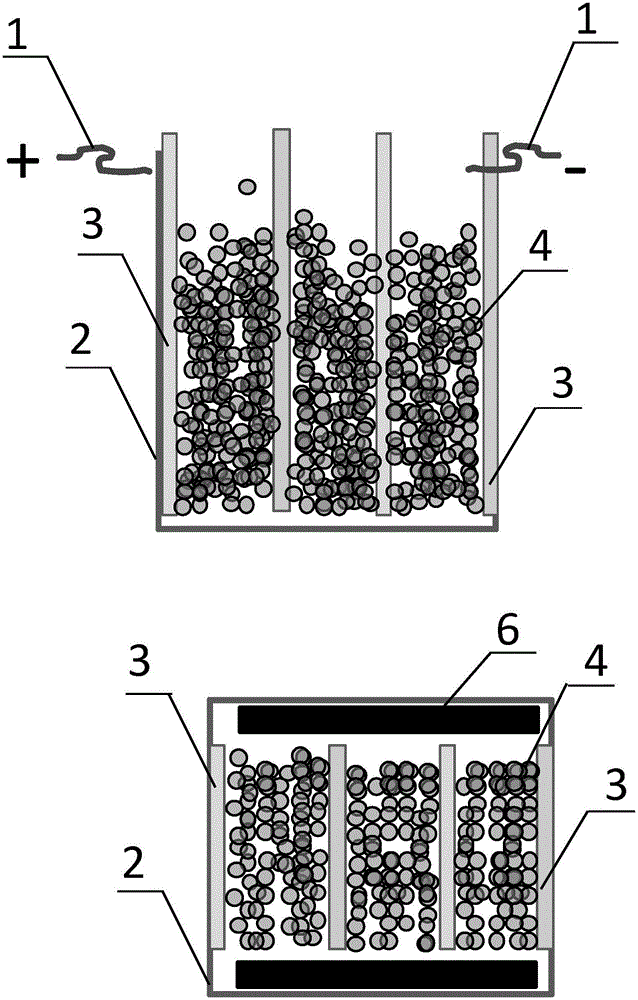

[0032] The outermost plate of the reactor is made of titanium mesh and activated carbon fiber; the middle plate is made of four kinds of titanium mesh, conductive glass, graphite and iron plate, arranged at intervals, and the distance between the plates is 5mm; the effective volume of the reactor is 3.0L. The nanometer zero-valent iron is placed in the reactor and mixed mechanically; the DC power supply is used for pole inversion operation every 5 minutes.

[0033] Adjust the pH value of the water to be treated to 2.8, adjust the DC power supply current to 50mA, and the current density to 0.2mA / cm 2 ; The concentration of arsenic in the water to be treated is 5 mg / L, and the concentration of arsenic in the effluent after flowing through the reactor reaches the industrial wastewater discharge standard (<0.5 mg / L).

Embodiment 2

[0035] The outermost plate of the reactor is made of diamond and graphite; the middle plate is made of five kinds of titanium mesh, activated carbon fiber, graphite, aluminum plate and iron plate, arranged at intervals, and the distance between the plates is 5mm; the effective volume of the reactor is 5.0L. Put the iron powder in the reactor, and use air to stir and mix; the DC power supply performs the electrode reversal operation every 240 minutes.

[0036] Adjust the pH value of the water to be treated to 3.2, adjust the DC power supply current to 150mA, and the current density to 5mA / cm 2 ; The concentration of lead in the water to be treated is 1mg / L, and the concentration of lead in the effluent after flowing through the reactor reaches the waste water discharge standard.

Embodiment 3

[0038]The outermost plate of the reactor is made of conductive glass or graphite; the middle plate is made of iron plate, and the distance between the plates is 20mm; the effective volume of the reactor is 100L. The iron filings are placed in the reactor, which is a fixed bed reactor, and the DC power supply is operated every 120 minutes.

[0039] The pH value of the water to be treated is adjusted to 4.5, the DC power supply current is adjusted to 600mA, and the current density is 20mA / cm2; the concentration of nitrobenzene in the water to be treated is 1 mg / L, and the concentration of nitrobenzene drops by 80% after passing through the reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com