Method for co-producing ammonium molybdate and sulfuric acid through treating molybdenite by oxygen-pressure water soaking process

A technology for molybdenite and ammonium molybdate is applied in the field of oxygen pressure water leaching treatment of molybdenite to co-produce ammonium molybdate and sulfuric acid, which can solve the problems of high cost of valuable components and consumption of sodium hydrosulfide, and achieve a simple process. , Improve production efficiency, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

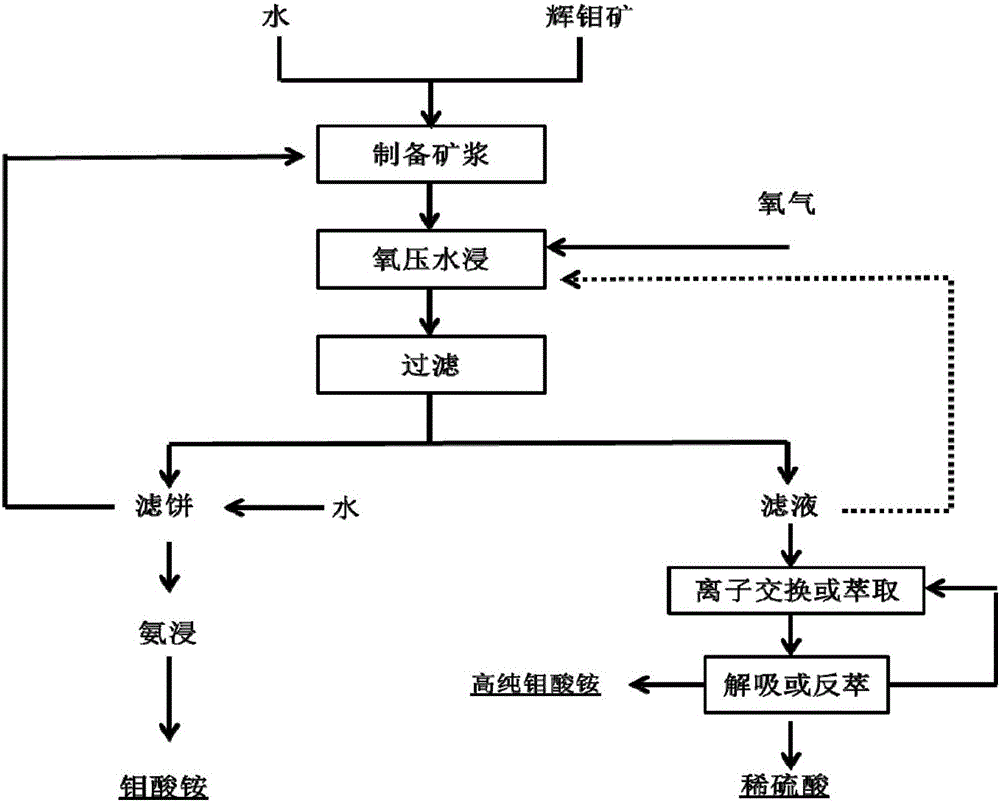

[0065] In the present embodiment, the molybdenite is prepared and processed to co-produce ammonium molybdate and sulfuric acid by the following method, which specifically includes the following steps (the schematic flow chart is as follows: figure 1 shown):

[0066] (1) Mix molybdenite powder containing 45% molybdenum less than 250 meshes with water evenly at a solid-to-liquid ratio of 1:2 (g:mL) to make molybdenite slurry;

[0067] (2) inject the molybdenite slurry into the pressure reactor, and carry out the oxygen pressure water immersion reaction with the oxidizing gas with a partial pressure of 1MPa at a temperature of 200°C for 1.5h;

[0068] (3) filtering the slurry obtained in step (2) to obtain filter cake and filtrate;

[0069] (4) the filter cake that step (3) is obtained is obtained ammonium molybdate product through ammonia immersion, filtration, crystallization;

[0070] (5) The filtrate obtained in step (3) is subjected to molybdenum removal treatment, the fil...

Embodiment 2

[0075] In the present embodiment, the molybdenite is prepared and processed to co-produce ammonium molybdate and sulfuric acid by the following method, which specifically includes the following steps (the schematic flow chart is as follows: figure 1 shown):

[0076] (1) Mix molybdenite powder less than 250 meshes and containing 58% molybdenum with water evenly at a solid-to-liquid ratio of 1:7 (g:mL) to make molybdenite slurry;

[0077] (2) inject the molybdenite slurry into the pressure reactor, and carry out the oxygen pressure water immersion reaction with the oxidizing gas with a partial pressure of 1.5MPa at a temperature of 180°C for 4h;

[0078] (3) filtering the slurry obtained in step (2) to obtain filter cake and filtrate;

[0079] (4) the filter cake that step (3) obtains makes ammonium molybdate product through ammonia immersion, filtration, crystallization;

[0080] (5) The filtrate obtained in step (3) is subjected to molybdenum removal treatment, the filtrate ...

Embodiment 3

[0084] In the present embodiment, the molybdenite is prepared and processed to co-produce ammonium molybdate and sulfuric acid by the following method, which specifically includes the following steps (the schematic flow chart is as follows: figure 1 shown):

[0085] (1) Mix molybdenite powder less than 100 mesh and containing 47% molybdenum with water evenly at a solid-to-liquid ratio of 1:6 (g:mL) to make molybdenite slurry;

[0086] (2) inject the molybdenite slurry into the pressure reactor, and carry out oxygen pressure water immersion reaction with an oxidizing gas with a partial pressure of 0.5MPa at a temperature of 220°C for 2h;

[0087] (3) filtering the slurry obtained in the second step above to obtain filter cake and filtrate;

[0088] (4) filter cake after washing makes ammonium molybdate product through ammonia leaching, filtration, crystallization etc.;

[0089] (5) The filtrate obtained in the third step above is subjected to molybdenum removal treatment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com