Preparation method of ultrathin graphite phase carbon nitride

A graphitic carbon nitride, ultra-thin technology, applied in the field of materials, can solve the problems of large thickness of graphitic carbon nitride sheets, restricting large-scale mass production, and high difficulty in preparation process operation, so as to avoid structural defects and environmental pollution. problems, no heavy metal pollution, cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

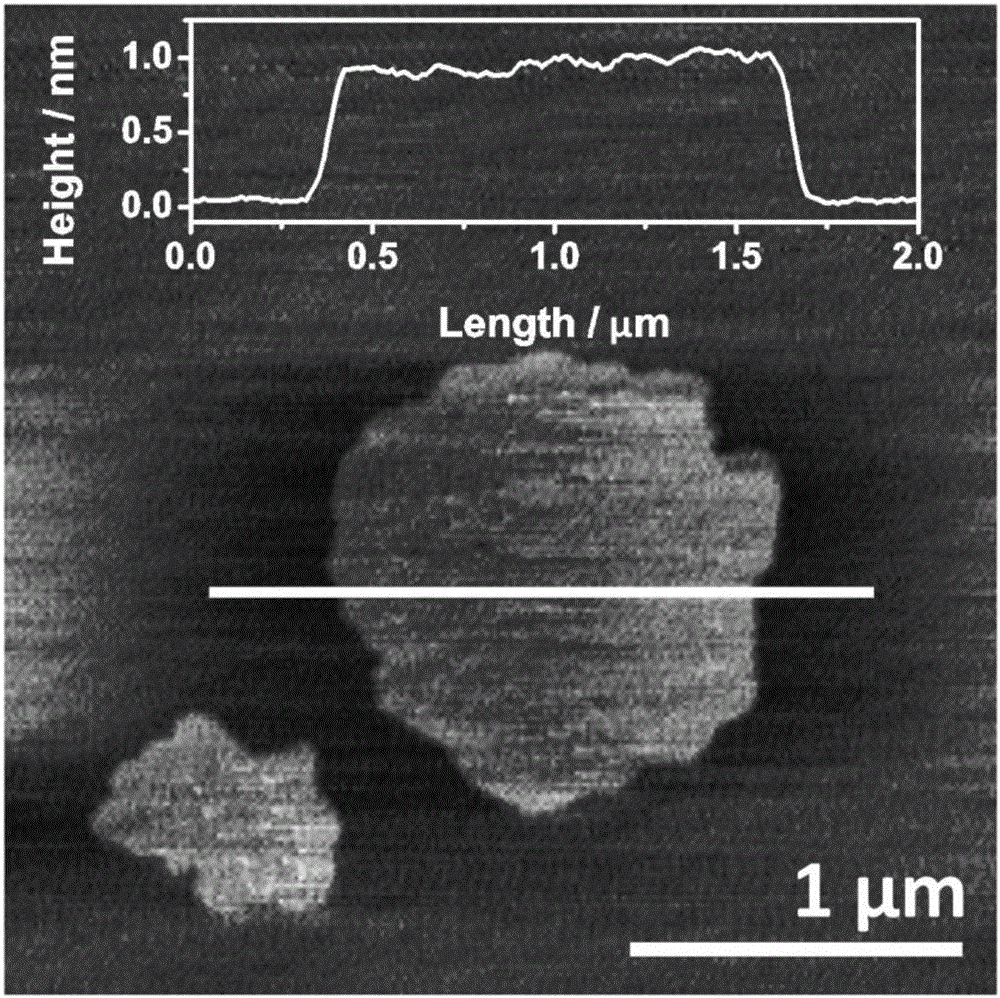

[0035] 1) Put melamine in a crucible, put it into an ash furnace, raise the temperature from room temperature to a calcination temperature of 520°C at a rate of 5°C / min, then calcinate at the calcination temperature for 4h, and then cool naturally to room temperature to obtain Lumpy g-C 3 N 4 ;

[0036] 2) Take 500mg of block g-C prepared in step 1) 3 N 4 , placed in a glass vessel with a volume of 250mL, add 200mL of deionized water, insert the probe of the ultrasonic cell breaker into the block g-C 3 N 4 In the deionized water mixture, the probe is 1cm deep into the liquid surface, the probe diameter is 10mm, the ultrasonic power is 900W, and the ultrasonic crushing is 90min;

[0037] 3) The obtained product was centrifuged at a speed of 8000r / min for 15min, and then the solid obtained after centrifugation was dried in a vacuum oven at 60°C for 12h;

[0038] 4) Transfer the dried solid into a crucible, then put it into an ash furnace, raise the temperature from room te...

Embodiment 2

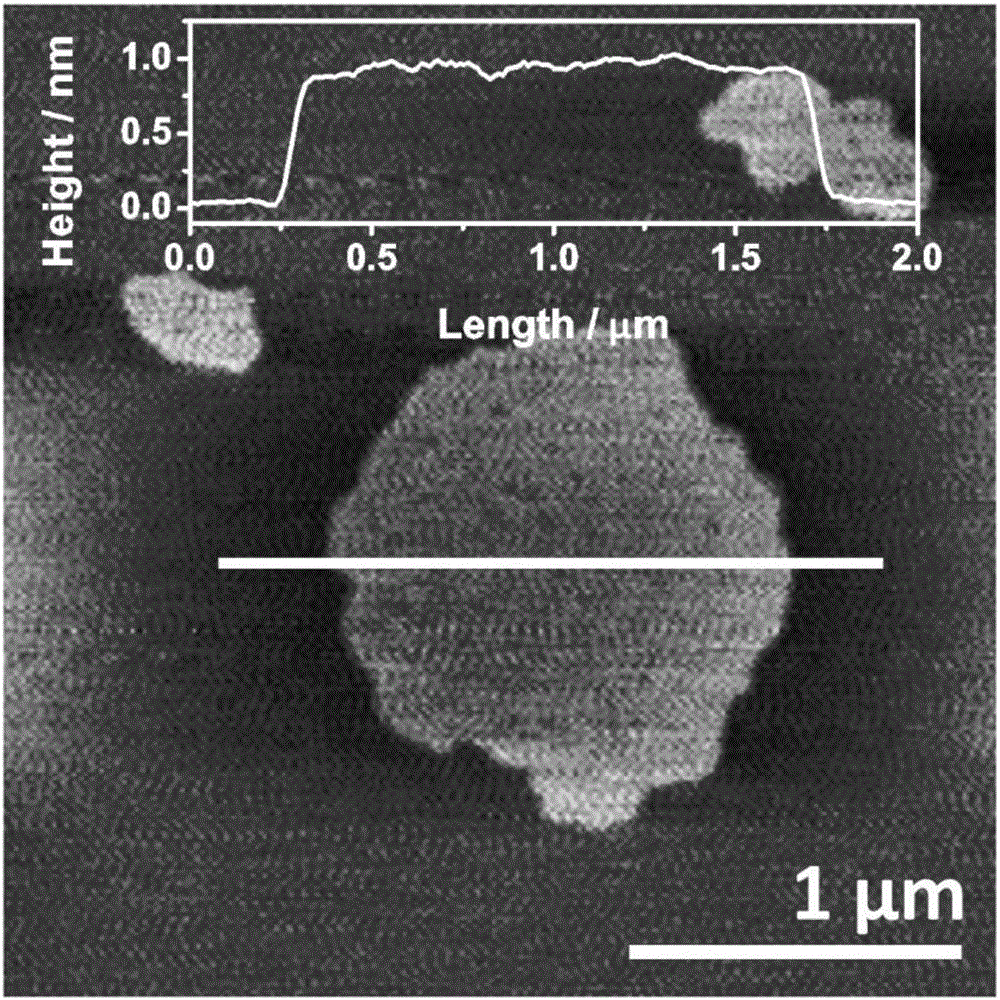

[0040] 1) Put melamine in a crucible, then put it into an ash furnace, raise the temperature from room temperature to a calcination temperature of 520°C at a rate of 10°C / min, then calcinate at the calcination temperature for 4h, and then cool naturally to room temperature to obtain Lumpy g-C 3 N 4 ;

[0041] 2) Take 500mg of block g-C prepared in step 1) 3 N 4 , placed in a glass vessel with a volume of 250mL, add 150mL of deionized water, insert the probe of the ultrasonic cell breaker into the block g-C 3 N 4 In the deionized water mixture, the probe penetrates 1cm into the liquid surface, the diameter of the probe is 10mm, the ultrasonic power is 600W, and the ultrasonic crushing is 120min;

[0042] 3) The obtained product was centrifuged at a speed of 12000r / min for 5min, and then the solid obtained after centrifugation was dried in a vacuum oven at 80°C for 10h;

[0043] 4) Transfer the dried solid into a crucible, put it into an ash furnace, raise the temperature ...

Embodiment 3

[0045] 1) Put melamine in a crucible, then put it into an ash furnace, raise the temperature from room temperature to a calcination temperature of 520°C at a rate of 5°C / min, then calcinate at the calcination temperature for 3h, and then cool naturally to room temperature to obtain Lumpy g-C 3 N 4 ;

[0046] 2) Take 500mg of block g-C prepared in step 1) 3 N 4 , placed in a glass vessel with a volume of 250mL, add 200mL of deionized water, insert the probe of the ultrasonic cell breaker into the block g-C 3 N 4 In the deionized water mixture, the probe penetrates 1cm into the liquid surface, the diameter of the probe is 10mm, the ultrasonic power is 1200W, and the ultrasonic crushing is 60min;

[0047] 3) The obtained product was centrifuged at a speed of 10000r / min for 10min, and then the centrifuged solid was dried in a vacuum oven at 60°C for 12h;

[0048] 4) Transfer the dried solid into a crucible, then put it into the ash furnace, raise the temperature from room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com