Clothes hanger PE pipe compositing process

A technology of clothes hanger and process, which is applied in the field of composite process of clothes hanger PE pipe, which can solve the problems of poor lamination of steel belt and resin, insufficient bonding strength, etc., and achieve the effect of not easy to shift, fast heating speed and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

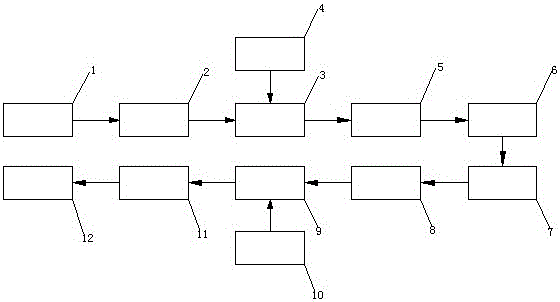

[0012] The present invention is a hanger PE pipe cladding process, the specific steps are as follows:

[0013] a. The steel strip is released from the uncoiler 1, and the steel strip is straightened by the steel strip straightener 2, and the speed of the steel strip is set at 3.5m / min.

[0014] b. Pre-heat the corrected steel strip with a high-frequency heating machine. The frequency of the high-frequency heating machine is set to 700Hz, and the temperature is 100°C. Then it passes through the extrusion die 3. Extruder 4 simultaneously extrudes resin and wraps it around the steel strip to form a strip, and at the same time, extrusion die 3 performs initial shaping of the strip. The speed of extruder 4 is set at 38.8 rpm, and the outlet temperature is 200°C.

[0015] c. After the strip is initially shaped, the ribs of the strip are shaped again through the shaping die 5, and at the same time, the shaping table 6 is cooled by cooling water. The re-setting is a total of 4 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com