A kind of preparation method of macroporous alumina microsphere

A technology of alumina and large pore volume, which is applied to the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., can solve the problems of affecting the catalytic effect of microspheres and the low pore volume of γ-alumina microspheres, and achieve the goal of preparing The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

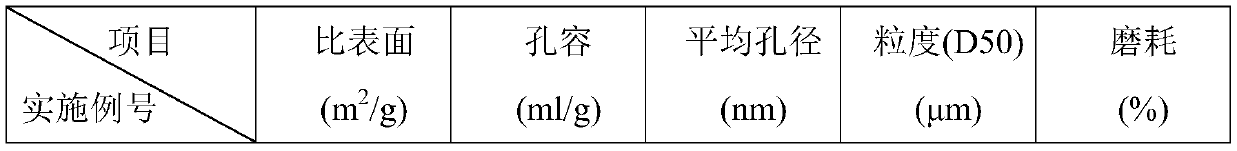

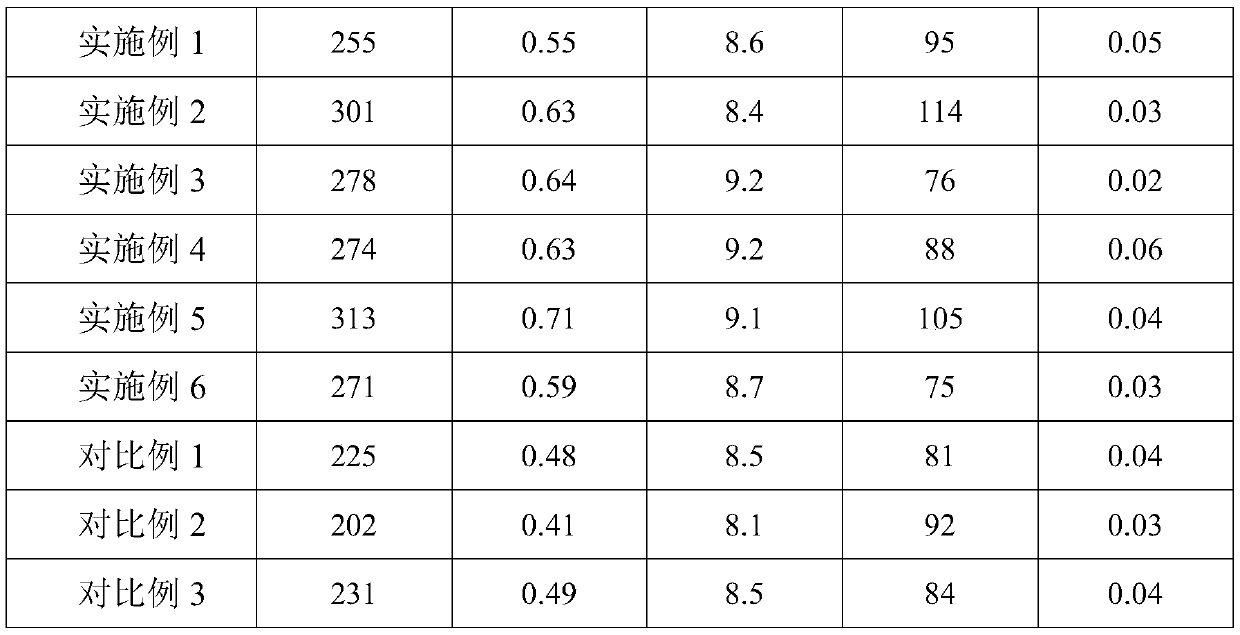

Embodiment 1

[0019] Add 500g of amorphous alumina to 2000g of deionized water and beat and disperse to obtain an alumina slurry, slowly add 60g of nitric acid with a concentration of 63% to the rapidly stirred alumina slurry, heat to 50°C for 8 hours; then add 32g of Uroto product, 6g PEG, 100g liquid paraffin, fully emulsified in an emulsifier to obtain an emulsified suspension; use a centrifugal spray dryer for spray granulation to obtain a precursor of alumina microspheres; finally, the obtained precursor was roasted at 550 ° C for 6h The γ-alumina microspheres were obtained; the specific surface, pore volume, pore size, particle size and wear index are shown in Table 1.

Embodiment 2

[0021] Add 500g of amorphous alumina to 2000g of deionized water and beat and disperse to obtain alumina slurry, slowly add 100g of nitric acid with a concentration of 63% to the rapidly stirred alumina slurry, heat to 60°C for 3 hours; then add 60g of Uroto product, 3g PEG, 60g liquid paraffin, fully emulsified in an emulsifier to obtain an emulsified suspension; use a centrifugal spray dryer for spray granulation to obtain a precursor of alumina microspheres; finally, the obtained precursor was roasted at 600°C for 6h The γ-alumina microspheres were obtained; the specific surface, pore volume, pore size, particle size and wear index are shown in Table 1.

Embodiment 3

[0023] Add 500g of amorphous alumina to 9500g of deionized water and beat and disperse to obtain alumina slurry, slowly add 180g of nitric acid with a concentration of 63% to the rapidly stirred alumina slurry, heat to 60°C for 3 hours; then add 27g of Uroto product, 10g Tween80, 150g liquid paraffin, fully emulsified in an emulsifier to obtain an emulsified suspension; spray granulation with a centrifugal spray dryer to obtain a precursor of alumina microspheres; finally, the obtained precursor was roasted at 500 ° C for 8 hours The γ-alumina microspheres were obtained; the specific surface, pore volume, pore size, particle size and wear index are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com