Chlorine dioxide stabilizing medium, preparation method, and disinfecting liquid prepared from chlorine dioxide stabilizing medium

A chlorine dioxide, chlorine dioxide fruit and vegetable technology, applied in the field of disinfectant solution, can solve problems such as instability, unfavorable use of ClO2, and inability to maintain the freshness and sterilization of fruits and vegetables, and achieve the effect of slowing down the rate of escaping solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

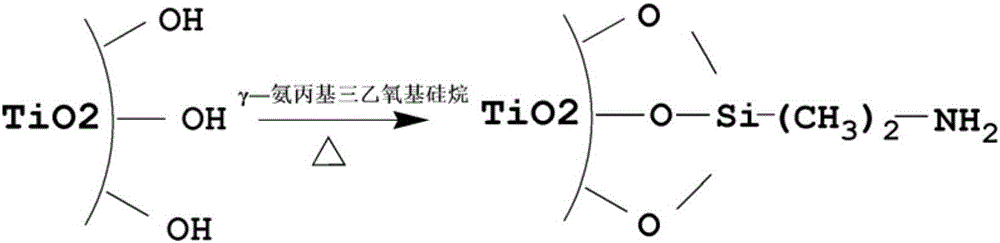

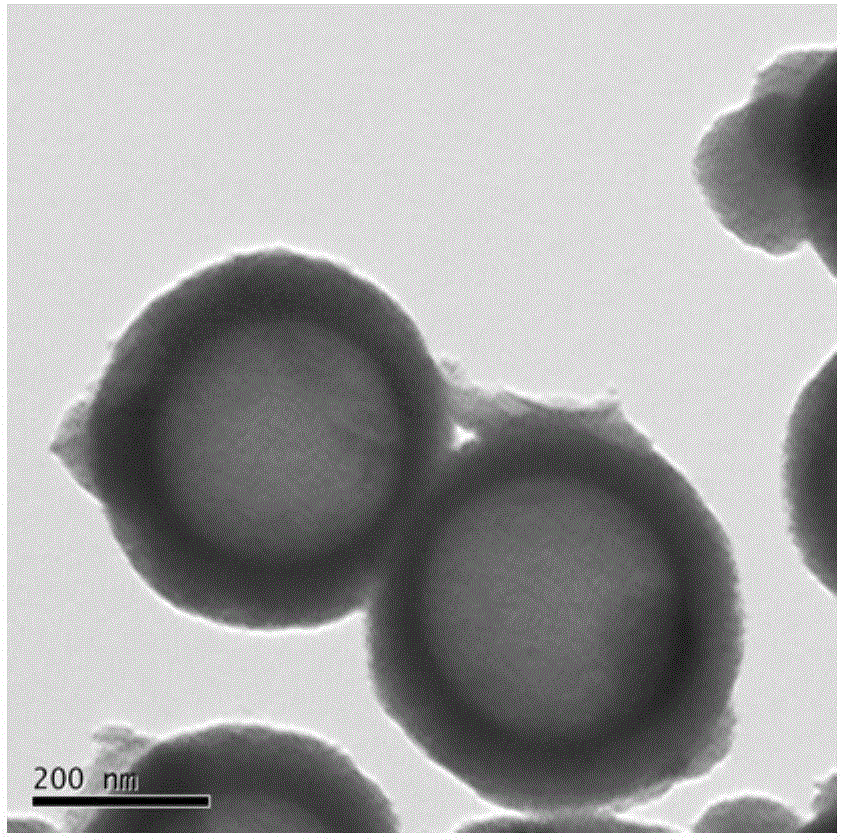

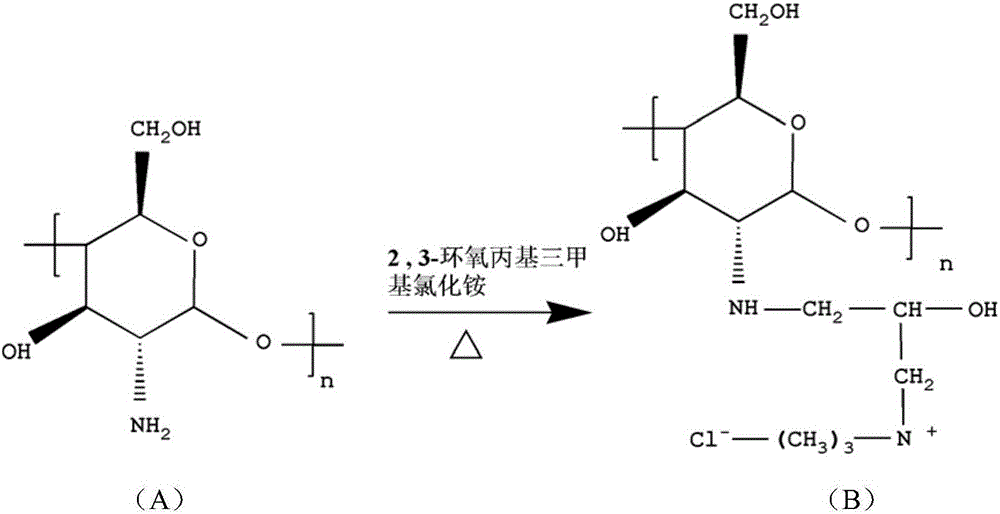

[0078] (1) Modified nano-TiO 2 Preparation of capsules:

[0079] Spherical SiO with an average particle size of 100nm will be prepared by the Stober method (refer to "Li Zi. Preparation and Characterization of Monodisperse Silica Microspheres. Chinese Ceramics: 2012 (48) 6: 12-16") 2 Nano powder 0.5g, through ultrasonic (1W / cm 2 , 30min) uniformly dispersed in 500mL absolute ethanol. Add 0.5g of dodecylamine and 1.0mL of butyl titanate successively under the emulsifying shear machine at room temperature and 8000rpm speed, react for 4 hours, filter with suction, transfer the obtained powder into a 50mL reaction kettle, and dissolve in 40mL absolute ethanol-deionized Water-ammonia mixed solution (ammonia concentration 26% by mass) (1:1:0.5, v / v) was subjected to hydrothermal treatment at 140°C for 16 hours, suction filtered, and the solid was taken to obtain a silicon-bearing precursor. The obtained silicon-bearing precursor was calcined at 400°C to remove the organic templat...

Embodiment 2

[0090] (1) Modified nano-TiO 2 Preparation of capsules:

[0091] Spherical SiO with an average particle size of 100 nm was prepared by the Stober method 2 Nano powder 1.0g, through ultrasonic (1W / cm 2 , 30min) uniformly dispersed in 500mL absolute ethanol. At room temperature, add 0.8g of dodecylamine and 1.5mL of butyl titanate successively under the 10000rpm rotating emulsification shearing machine, react for 5 hours, filter with suction, transfer the obtained powder into a 50mL reaction kettle, and dissolve in 40mL of absolute ethanol-deionized Water-ammonia water mixed solution (the concentration of ammonia water is 26% by mass) (1:1:0.5, v / v) was subjected to hydrothermal treatment at 150° C. for 17 hours, suction filtered, and the solid was taken to obtain a silicon-bearing precursor. After the silicon-bearing precursor was calcined at 600°C to remove the organic template, it was transferred to a 50mL reactor again, treated with 40mL of 1.0M sodium hydroxide solution ...

Embodiment 3

[0099] (1) Modified nano-TiO 2 Preparation of capsules:

[0100] Spherical SiO with an average particle size of 100 nm was prepared by the Stober method 2 Nano powder 1.5g, through ultrasonic (1W / cm 2 , 30min) uniformly dispersed in 500mL absolute ethanol. At room temperature, 1.0g of dodecylamine and 2.0mL of butyl titanate were sequentially added to an emulsifying shear machine at a speed of 12000rpm. After reacting for 6 hours, suction filtration was performed, and the obtained powder was transferred to a 50mL reaction kettle, and the The water-ammonia water mixed solution (the concentration of ammonia water is 26% by weight) was subjected to hydrothermal treatment at 160° C. for 18 hours under conditions (1:1:0.5, v / v), filtered by suction, and the solid was collected to obtain a silicon-bearing precursor. After the silicon-bearing precursor was calcined at 600°C to remove the organic template, it was transferred to a 50mL reaction kettle again, and was treated with 40m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com