Preparation and processing method and application of 1,3-propanediol fermentation liquid, preparation method of water-soluble fertilizer and water-soluble fertilizer

A treatment method and fermentation broth technology, applied in the application, sewage/sludge fertilizer, potash fertilizer and other directions, can solve the problems of insufficient environmental protection and thoroughness, and achieve the effects of improving quality, reducing production costs and increasing fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

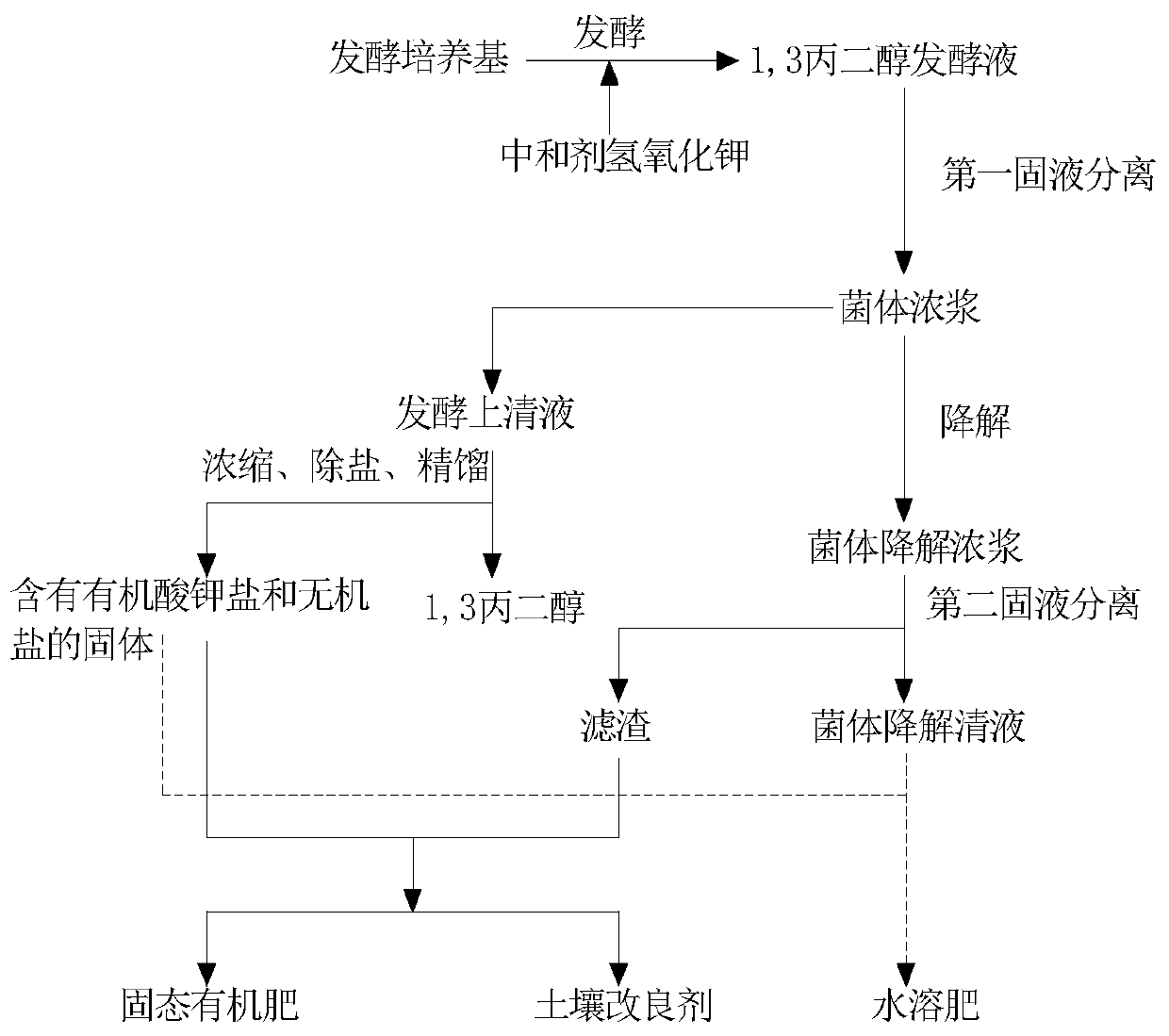

[0035] According to the present invention, in step 2), the separation method for separating 1,3-propanediol and the solid containing organic acid potassium salt and inorganic salt from the fermentation supernatant can be a conventional choice in the art. For example, concentration, desalting and rectification may be performed in sequence. According to a preferred embodiment of the present invention, the method for separating the fermentation supernatant comprises the following steps: by concentrating the fermentation supernatant, and then feeding it to a scraped film evaporator, obtaining Liquids of 1,3-propanediol and 2,3-butanediol, glycerin and water are obtained from the bottom of the tower as solids containing potassium salts of organic acids and inorganic salts. The liquid containing 1,3-propanediol, 2,3-butanediol, glycerin and water is rectified to obtain 1,3-propanediol.

[0036] In the present invention, the inorganic salt can be nitrogen salt and / or phosphorus salt...

Embodiment 1

[0055] This embodiment is used to illustrate the preparation and processing method and application of the fermentation liquid of 1,3-propanediol provided by the present invention and the preparation method of water-soluble fertilizer and water-soluble fertilizer

[0056] (1-1) Preparation method of fermented liquid of 1,3-propanediol

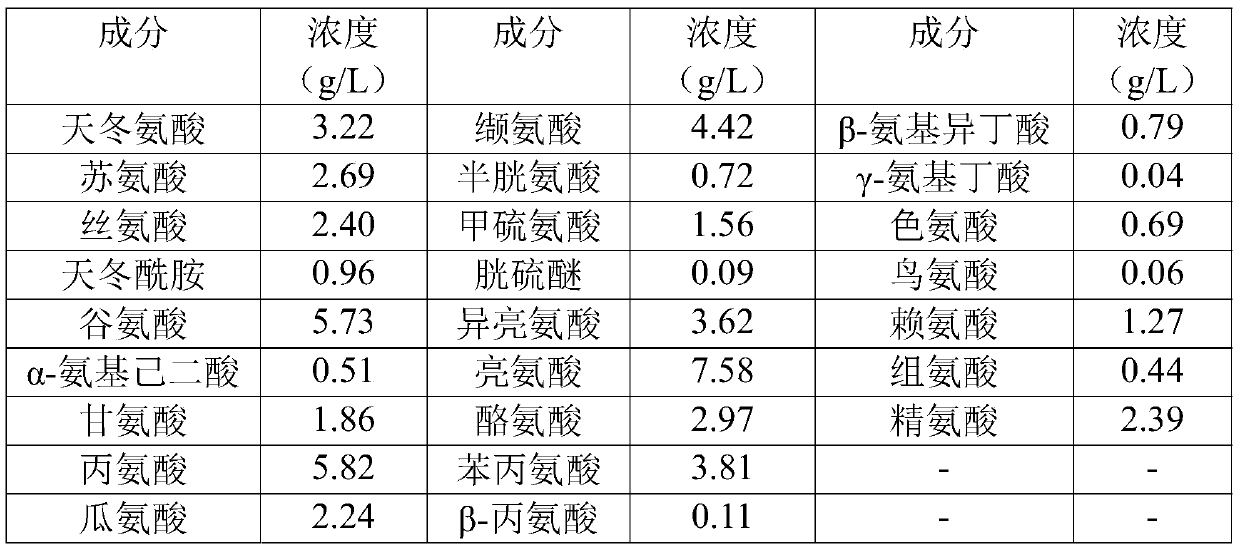

[0057] Klebsiella pneumoniae (Klebsiella) was inoculated into a fermenter containing a fermentation medium under aseptic conditions for fermentation. The fermentation temperature was 30° C., the stirring speed was 250 rpm, and the ventilation volume was 2.0 VVM. Use potassium hydroxide all (100% by weight) to replace sodium hydroxide to adjust the pH of the fermented liquid to be 6.5, when the concentration of 1,3-propanediol in the fermented liquid no longer rises, stop fermentation, obtain 1,3-propanediol fermented liquid, Its composition is listed in Table 1.

[0058] (1-2) The processing method of 1,3-propanediol fermentation broth

[0059...

Embodiment 2

[0080] This embodiment is used to illustrate the preparation and processing method and application of the fermentation liquid of 1,3-propanediol provided by the present invention and the preparation method of water-soluble fertilizer and water-soluble fertilizer

[0081] (2-1) Preparation method of fermented liquid of 1,3-propanediol

[0082] Klebsiella pneumoniae (Klebsiella) was inoculated into a fermenter containing a fermentation medium under aseptic conditions for fermentation. The fermentation temperature was 37° C., the stirring speed was 150 rpm, and the ventilation volume was 1.0 VVM. Use potassium hydroxide part (potassium hydroxide accounts for 75% by weight of neutralizing agent) to replace sodium hydroxide to adjust the pH of fermented liquid to be 6, when the concentration of 1,3-propanediol no longer rises in the fermented liquid, stop fermentation, obtain 1 , 3-propanediol fermentation broth, its composition is listed in table 5.

[0083] (2-2) The processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com