Copper-iron-carbon aerogel electrode preparation method

A carbon aerogel and electrode technology, applied in the field of water pollution control, can solve the problems of narrow pH range, low current efficiency, low hydrogen peroxide yield, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for fast and efficient treatment of DMP, using the electro-Fenton system, the copper-iron-carbon aerogel with simple preparation method, high reaction catalytic activity and easy recycling is used as the cathode, and the copper-iron-carbon aerogel The preparation of the electrode specifically includes the following steps:

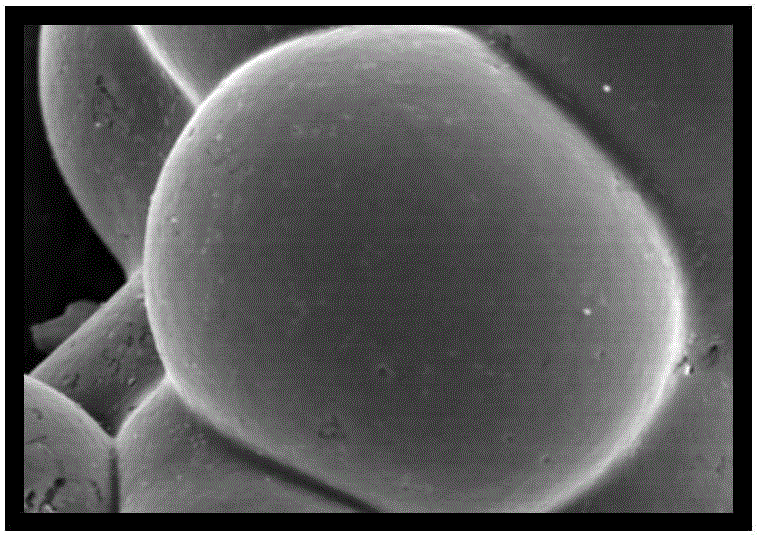

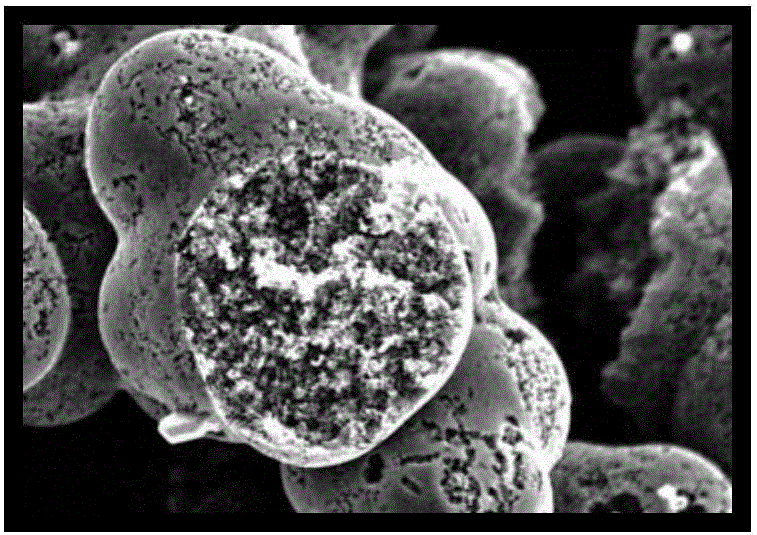

[0037] (1) Copper-iron-carbon airgel preparation

[0038] Weigh an appropriate amount of resorcinol, formaldehyde, water, and sodium carbonate, and then mix them with resorcinol: formaldehyde: water: sodium carbonate in a molar ratio of 1:2:17.5:0.0008. After forming a uniform solution, pour Iron acetylacetonate and copper acetate monohydrate powder are added to the precursor solution, wherein the mass ratio of the iron in the iron acetylacetonate to the carbon in the precursor solution is 1 to 3:100, and the copper in the copper acetate monohydrate and the precursor The mass ratio of carbon in the solution is 1-3:100, and it is poured into...

Embodiment 2

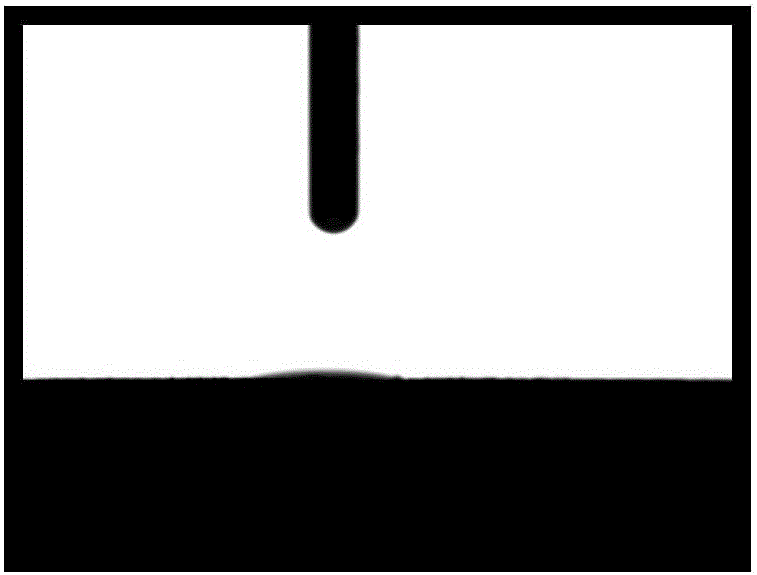

[0044] CuFe / CA, CuFe / CA-CO in embodiment 1 2 and CuFe / CA-CO 2 -N 2 It is applied to the electro-Fenton system to degrade DMP efficiently and quickly, and it is used as the cathode in the electro-Fenton system, where the anode is a boron-doped diamond (BDD) film electrode, and the copper-iron-carbon gas is fixed with glass glue The area of the gel electrode is about 3cm 2 , using two-electrode DC power supply, with 10 ~ 30mA / cm 2 The constant current density, the voltage of the system is about 4.5V ~ 5.5V. Put 50ml of DMP with a concentration of 50mg / L into 0.05mol / L of Na 2 SO 4 In order to carry out the degradation reaction in the electro-Fenton system to support the electrolyte, the solution in the electro-Fenton system is aerated with oxygen at a rate of 100-150mL / min for 15-20 minutes before the reaction, and the oxygen aeration rate is kept constant during the degradation reaction , take a sample every 15min, and use HPLC to measure the concentration of DMP. The ...

Embodiment 3

[0046] CuFe / CA, CuFe / CA-CO in embodiment 1 2 and CuFe / CA-CO 2 -N 2 It is applied to the electro-Fenton system to degrade the industrial dye methylene blue efficiently and quickly, and it is used as the cathode in the electro-Fenton system, in which the anode is a columnar graphite electrode, and the copper-iron-carbon airgel electrode is fixed with glass glue The area is about 3cm 2 , using two-electrode DC power supply, with 10 ~ 30mA / cm 2 The constant current density, the voltage of the system is about 4.5V ~ 5.5V. Put 50ml of methylene blue with a concentration of 50mg / L into 0.05M Na 2 SO 4 In order to support the degradation reaction in the electro-Fenton system of the electrolyte, the solution in the electro-Fenton system was aerated with oxygen at a rate of 100-150mL / min for 15-20 minutes before the reaction, and the oxygen aeration rate was kept constant during the degradation reaction. Samples were taken every 15 min, and the concentration of methylene blue was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com