Method for manufacturing silicon carbide semiconductor device

A manufacturing method and technology of silicon carbide, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as increased leakage current, and achieve the effect of good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

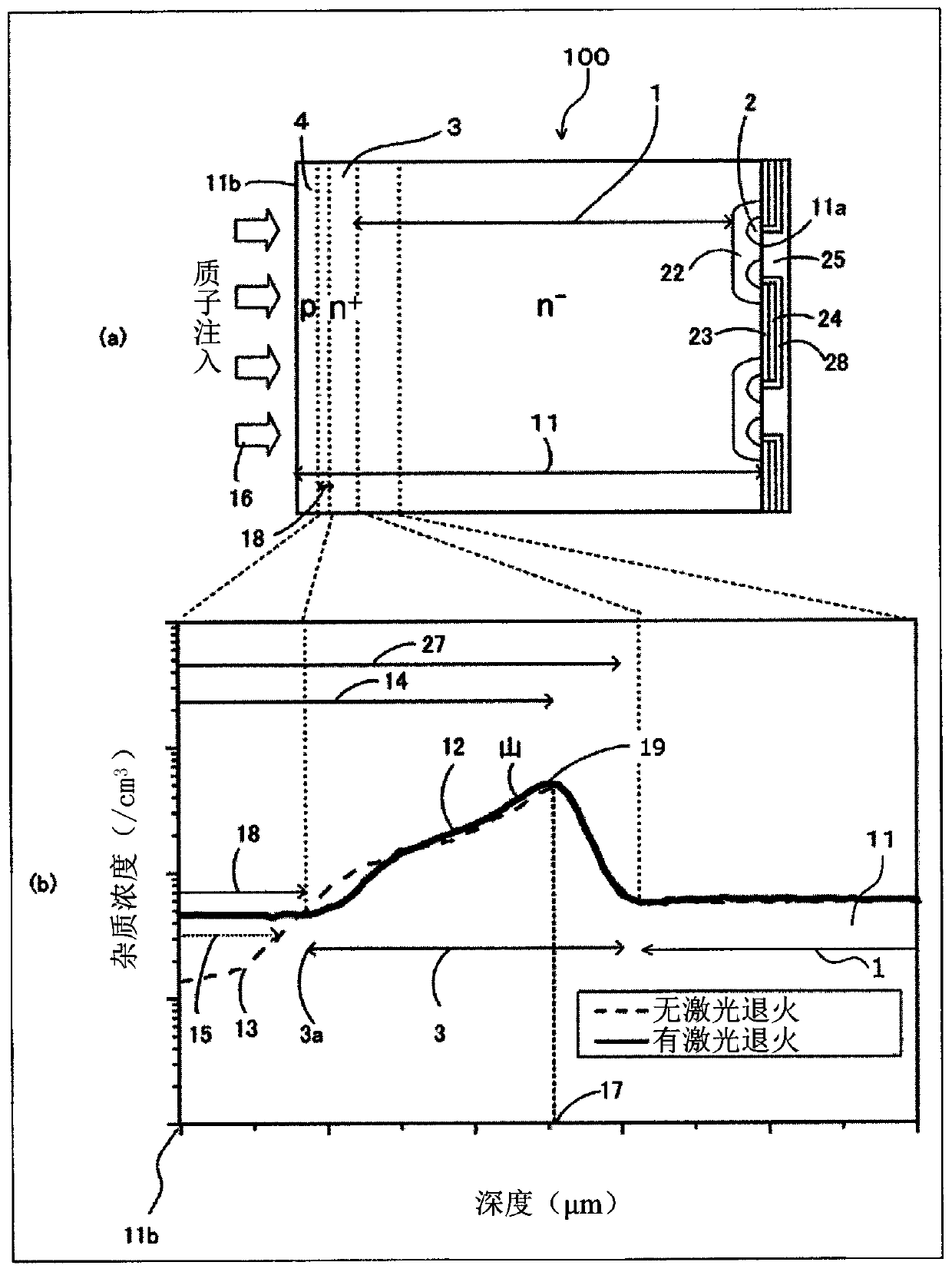

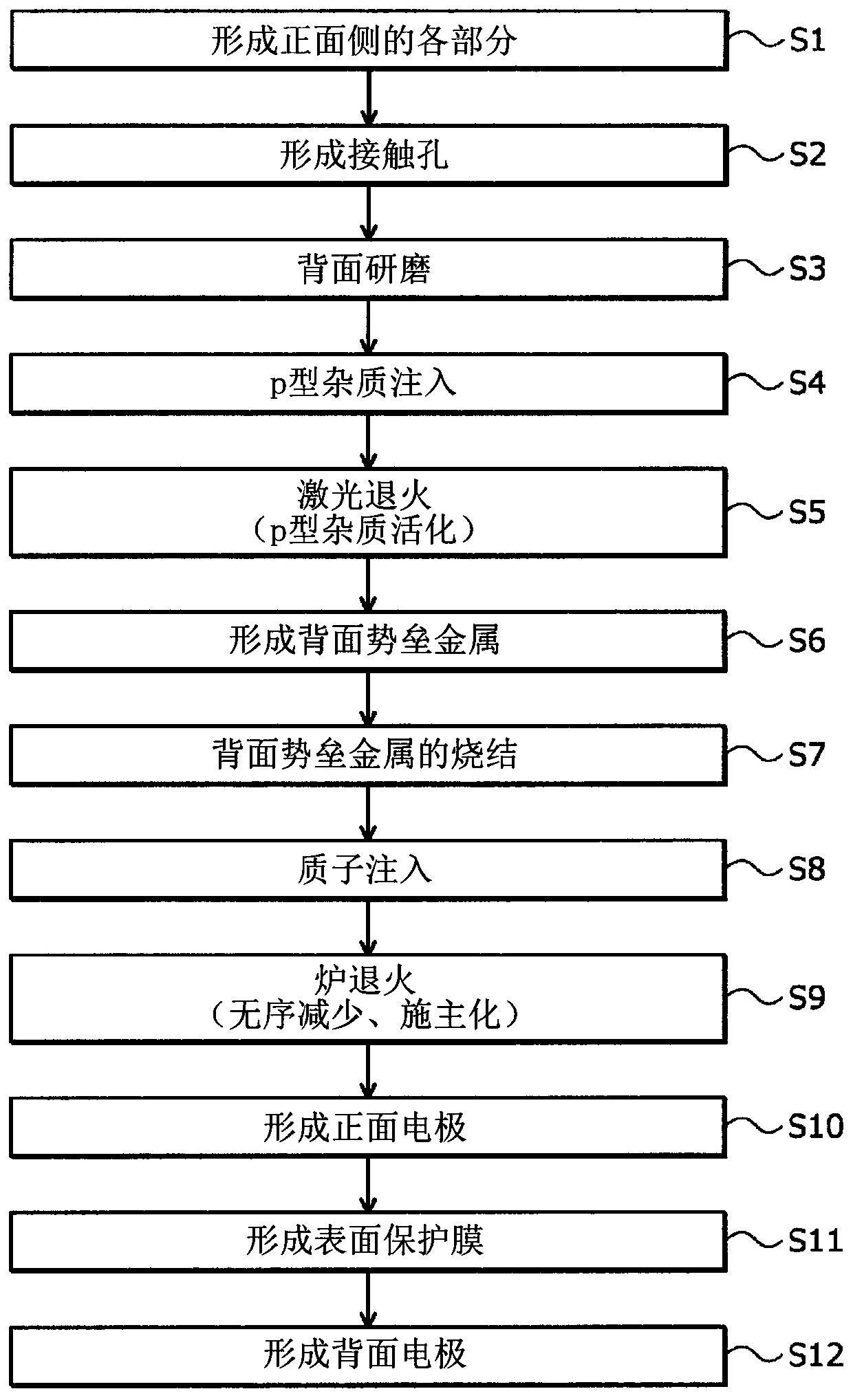

[0080] As an example of a silicon carbide semiconductor device fabricated by the method of manufacturing a silicon carbide (SiC) semiconductor device according to Embodiment 1, a structure of a planar gate type IGBT (hereinafter referred to as SiC-IGBT) will be described. figure 1 It is an explanatory diagram showing the structure of a semiconductor device manufactured by the method of manufacturing a silicon carbide semiconductor device according to the first embodiment. figure 1 (a) shows a cross-sectional view of main parts of SiC-IGBT 100, figure 1 (b) shows n + The doping concentration curve near the type field stop layer 3. Such as figure 1 As shown, the silicon carbide semiconductor device of Embodiment 1 becomes n - type drift layer 1 n - The front side 11a side of the silicon carbide substrate (semiconductor chip) 11 is provided with a p-type base (base) region 22, n + A MOS gate structure composed of a type emitter region 2, a gate insulating film 23 and a gate ...

Embodiment approach 2

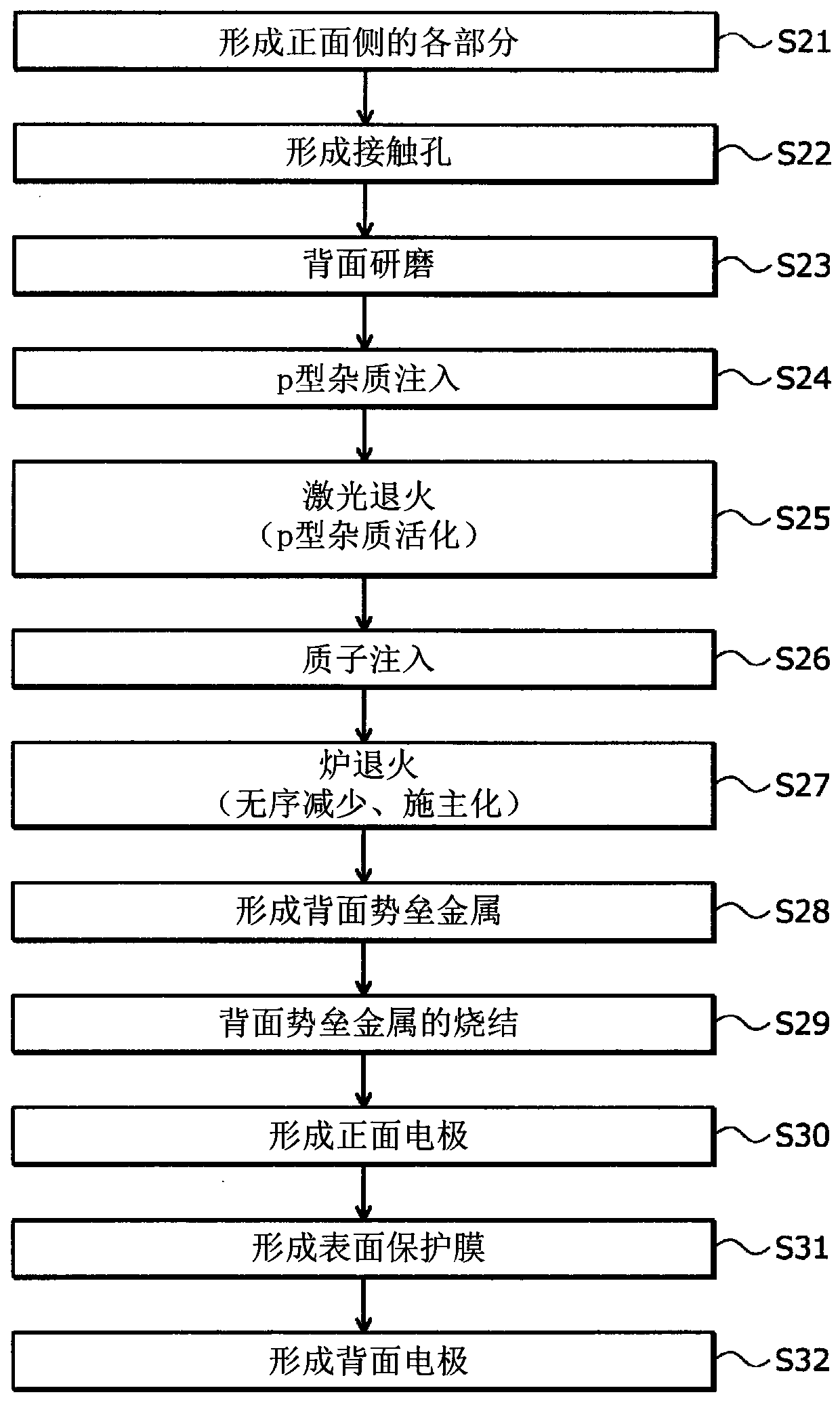

[0105] Next, a method of manufacturing a silicon carbide semiconductor device according to Embodiment 2 will be described. Figure 3A It is a flowchart showing the outline of a method of manufacturing a silicon carbide semiconductor device according to the second embodiment. The difference between the method of manufacturing a silicon carbide semiconductor device in Embodiment 2 and the method of manufacturing a silicon carbide semiconductor device in Embodiment 1 is that the formation of the back barrier metal and the sintering of the back barrier metal are combined with proton injection 16 and furnace annealed for a replacement pair.

[0106] Specifically, after the steps from formation of each part on the front side to laser annealing (steps S21 to S25) are sequentially performed in the same manner as in the first embodiment, proton implantation 16, furnace annealing, back barrier metal The steps of forming and sintering the back barrier metal (steps S26 to S29). The meth...

Embodiment approach 3

[0109] Next, a method of manufacturing a silicon carbide semiconductor device according to Embodiment 3 will be described. Figure 3B It is a flowchart showing the outline of a method of manufacturing a silicon carbide semiconductor device according to the third embodiment. The difference between the manufacturing method of the silicon carbide semiconductor device in the third embodiment and the manufacturing method of the silicon carbide semiconductor device in the second embodiment is that the laser annealing is performed after the proton implantation 16 and before the formation of the back barrier metal.

[0110] Specifically, steps from formation of each portion on the front side to ion implantation of p-type impurities are sequentially performed in the same manner as in the first embodiment (steps S41 to S44 ). Next, proton injection 16 is performed (step S45). The method and condition of proton implantation 16 and step S8 of embodiment one (referring to figure 2 )same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com