Organosiloxane, curable silicone composition, and semiconductor device

A technology of organosiloxane and composition, which is applied in the field of curable silicone composition, can solve problems such as insufficient adhesion, and achieve the effect of excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

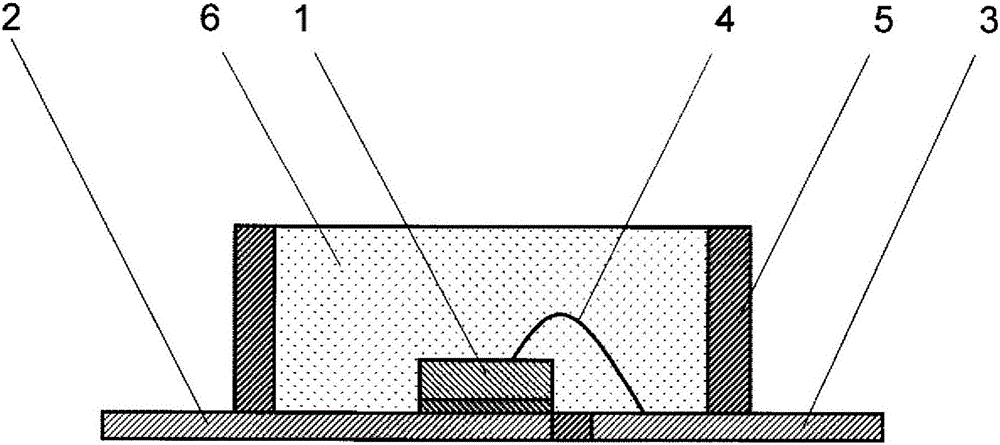

Image

Examples

preparation example Construction

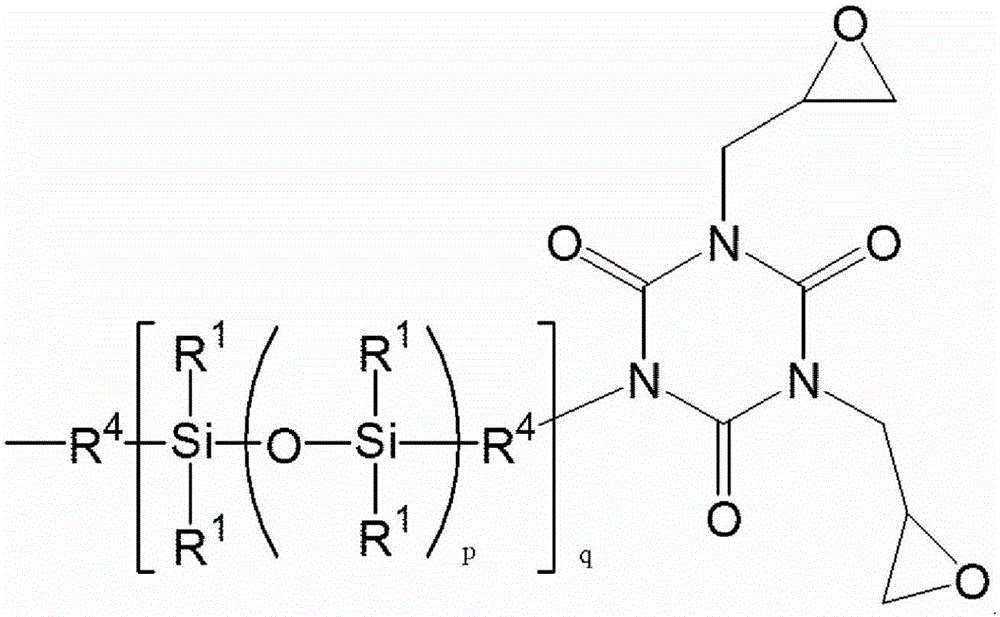

[0063] In the above-mentioned production method, it is necessary to react in an amount of at least 1 mol to 2 mol of the above-mentioned compound per 1 mol of the above-mentioned organosiloxane. This is because: when the amount of the above-mentioned compound is more than the lower limit of the above-mentioned range, the obtained organosiloxane can impart sufficient adhesiveness to the curable silicone composition; on the other hand, when the amount of the above-mentioned compound is When it is below the upper limit of the above range, the obtained organosiloxane reacts with the hydrogen atoms bonded to the silicon atoms in the hydrosilylation reaction-curable silicone composition, and the transmittance of the obtained cured product can be improved.

[0064] Examples of the acid used in the above production method include hydrochloric acid, acetic acid, formic acid, nitric acid, oxalic acid, sulfuric acid, phosphoric acid, polyphosphoric acid, polycarboxylic acid, trifluorometh...

Embodiment

[0131] The organosiloxane, curable silicone composition, and semiconductor device of the present invention will be described in detail by way of examples. In addition, in the formula, Me, Vi, Ph, and Ep respectively represent a methyl group, a vinyl group, a phenyl group, and a 3-glycidoxypropyl group.

reference example 1

[0133] Put 400g (2.02mol) of phenyltrimethoxysilane and 93.5g (0.30mol) of 1,3-divinyl-1,3-diphenyldimethyldisiloxane into the reaction vessel, after pre-mixing, 1.74 g (11.6 mmol) of trifluoromethanesulfonic acid was added, and 110 g (6.1 mol) of water was added with stirring, and heated to reflux for 2 hours. Thereafter, heating and atmospheric distillation were performed so that the temperature was 85°C. Next, 89 g of toluene and 1.18 g (21.1 mmol) of potassium hydroxide were charged, heated and distilled at atmospheric pressure until the reaction temperature reached 120° C., and reacted at this temperature for 6 hours. Then, it cooled to room temperature, and 0.68 g (11.4 mmol) of acetic acid was injected|thrown-in and neutralized. After the generated salt was filtered off, low boiling point substances were removed by heating and reducing pressure from the obtained transparent solution, and an average unit formula was prepared:

[0134] (MePhViSiO 1 / 2 ) 0.23 (PhSiO 3 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com