Package structure and method for light emitting diodes

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as short circuits, and achieve the effects of convenient use, saving processing costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

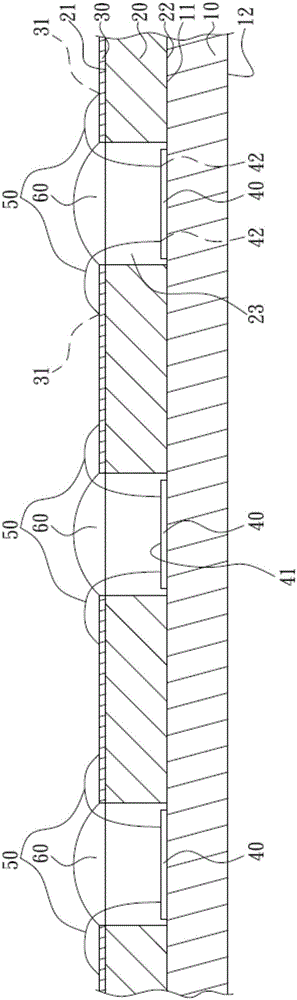

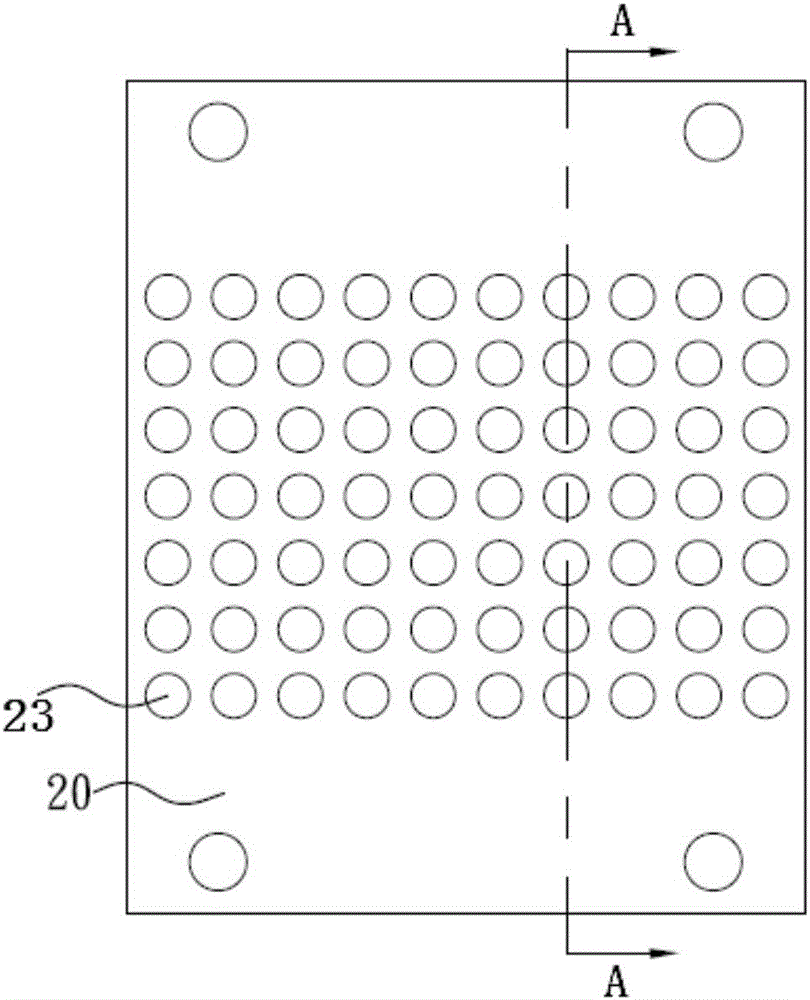

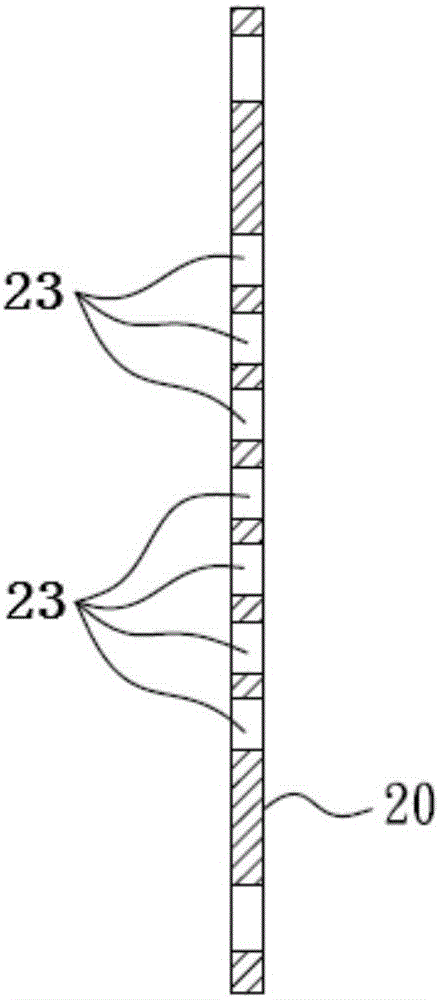

[0034] Such as Figure 1-Figure 4 As shown, this embodiment provides a preferred packaging structure of light emitting diodes, which includes a metal substrate 10, an insulating layer 20, an electrode layer 30, a plurality of LED chips 40, a plurality of bonding wires 50 and a plurality of Lens 60. Specifically, the metal substrate 10 has a front surface 11 and a back surface 12, wherein an insulating layer 20 is laminated on the front surface 11 of the metal substrate 10, the insulating layer 20 has a certain thickness, and a plurality of holes penetrating through the insulating layer 20 are opened on it. Through holes 23 on the front side 21 and the back side 22 . Here, a plurality of through holes 23 are arranged on the insulating layer 20 in an array, such as figure 2 Among them, the insulating layer 20 is provided with seven rows and ten columns of through holes 23, wherein the distance between two adjacent through holes 23 is equal, and the range of values thereof i...

Embodiment 2

[0041] This embodiment proposes a packaging method suitable for the above light-emitting diode packaging structure, which specifically includes the following steps:

[0042] Step A: provide a metal substrate 10, and stick a plurality of LED dies 40 on its front surface 11;

[0043] Here, a plurality of LED dies 40 are arranged in an array on the front surface 11 of the metal substrate 10 , and specifically can be arranged in a rectangular array, a circular array, an elliptical array, a triangular array, etc. as required. Moreover, each LED die 40 is provided with a second electrode group 42 , and the second electrode group 42 includes a second positive electrode and a second negative electrode.

[0044] Step B: providing an insulating layer 20, on which a plurality of through holes 23 are formed to correspond to a plurality of LED chips 40 one-to-one;

[0045] In this step, the insulating layer 20 has a certain thickness, which is greater than that of the LED die 40 , so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com