Method for preparing cobalt hydroxide/nickel hydroxide supercapacitor electrode based on metal titanium mesh substrate with high-conductivity ceramic surface film

A supercapacitor and ceramic surface technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of not meeting the application requirements, large capacity loss, poor rate performance, etc., and achieve simplified preparation and electrode assembly process , Improve the surface properties, improve the effect of binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

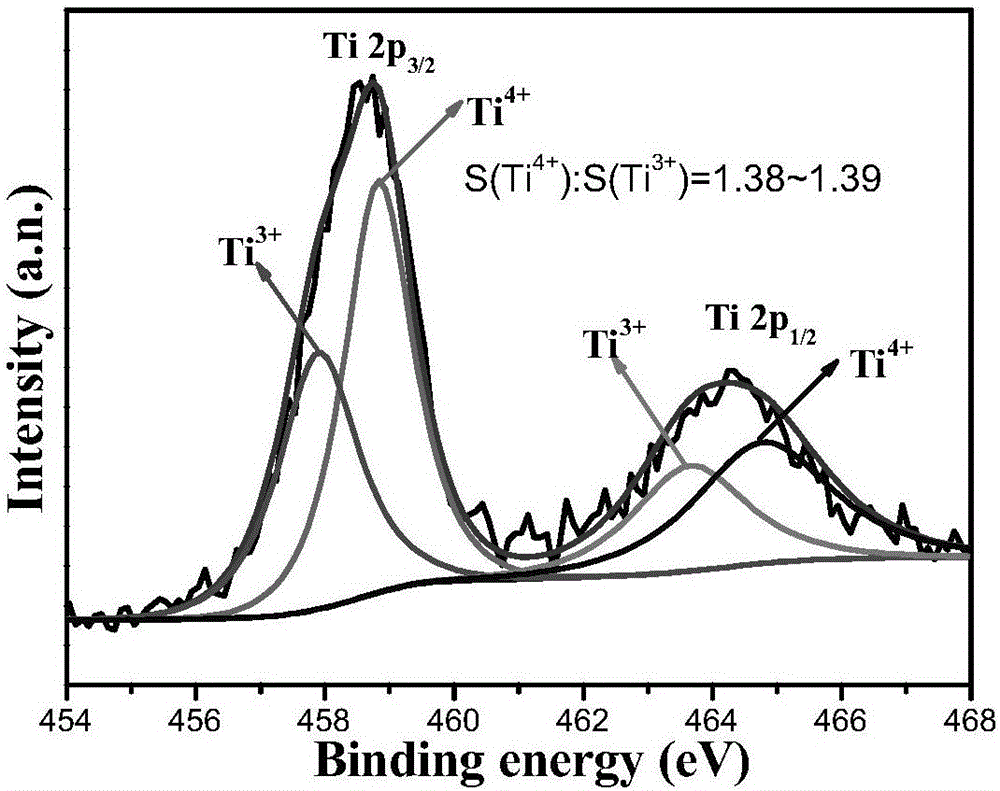

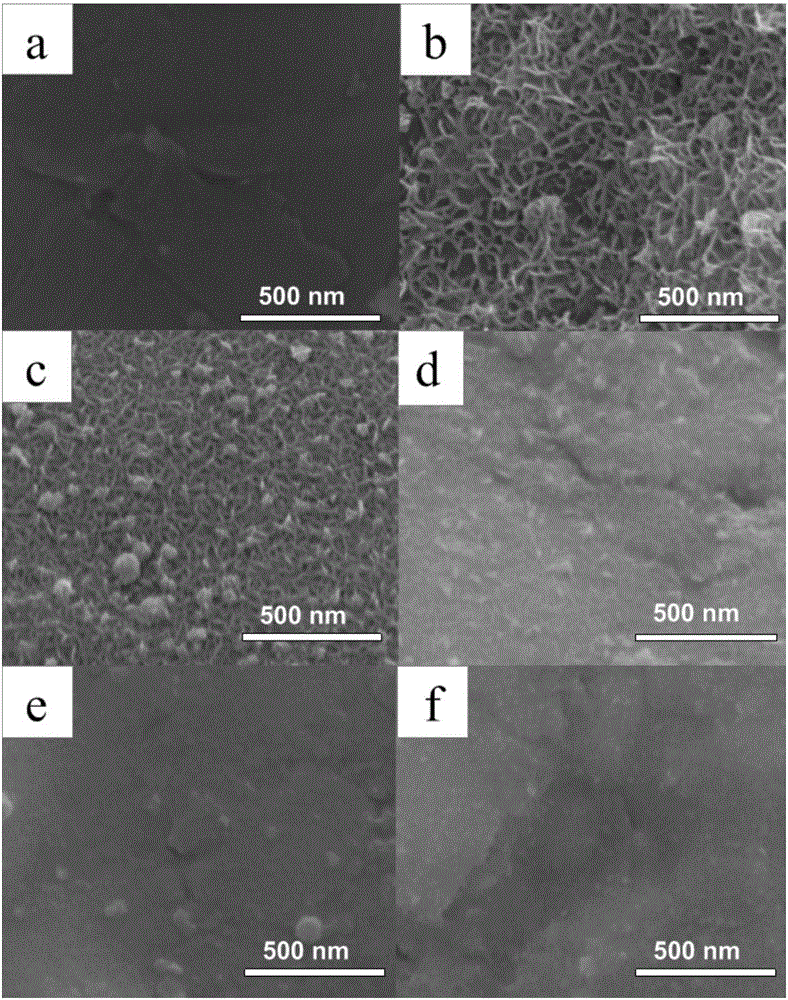

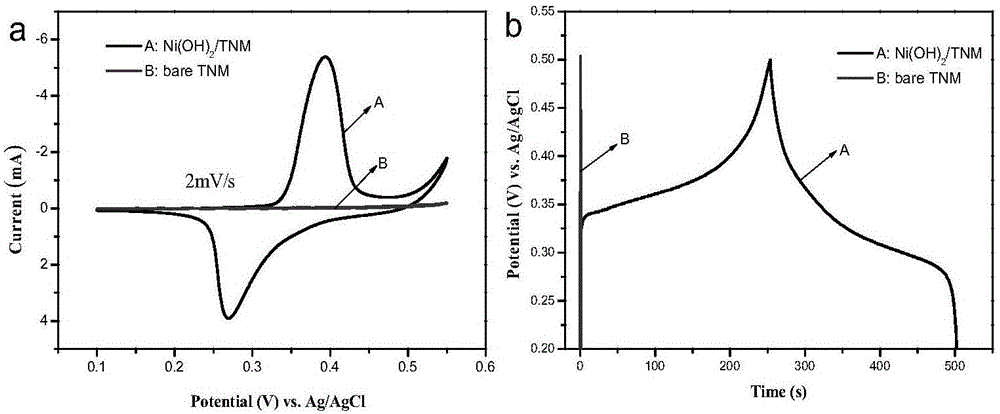

Embodiment 1

[0032] The titanium mesh used was subjected to reduction treatment at 900°C for 4 hours in a pure hydrogen atmosphere. The electrode size was 2.5cm×1.0cm. 0.1M nickel nitrate solution was used as the deposition electrolyte, and 1M KOH solution was used as the electrochemical test electrolyte. The three-electrode system uses titanium mesh as the working electrode, platinum sheet as the counter electrode, and Ag / AgCl as the reference electrode. The method of constant current cathodic polarization is adopted, and the current density is 1-25mA / cm 2 , the prepared deposition amount is 0.12mg / cm 2 Nickel hydroxide / titanium mesh electrode. The scanning electron microscope photos show that nickel hydroxide is evenly distributed on the titanium mesh, and has various shapes such as porous flower-like structure and granular shape. The results of cyclic voltammetry show that the composite material has small electrode polarization and high reversibility. Calculated from the charge and di...

Embodiment 2

[0035] The titanium mesh used was in a hydrogen / acetylene mixed atmosphere (P C2H4 :P H2 =0.02), after 1000°C reduction treatment for 2 hours, the electrode size is 2.5cm×1.0cm, 0.025M cobalt nitrate solution is prepared as deposition electrolyte, and 1M KOH solution is prepared as electrochemical test electrolyte. Using a three-electrode system with titanium mesh as the working electrode, platinum sheet as the counter electrode, and Ag / AgCl as the reference electrode, the method of constant current cathodic polarization is adopted, and the current density is 2mA / cm 2 , the reaction time is 200s, and the deposition amount is 0.24mg / cm 2 cobalt hydroxide / titanium mesh electrode. Scanning electron microscope observation shows that cobalt hydroxide is evenly distributed on the titanium mesh and has a porous flower-like structure. The results of cyclic voltammetry and charge-discharge show that the composite material has high reversibility. Calculated from the cyclic voltammet...

Embodiment 3

[0037] The unreduced titanium mesh and the titanium mesh (both specifications are 2.5cm×1.0cm) that have been reduced at 900°C for 4 hours in a pure hydrogen atmosphere were used as electrode collectors, and the method of constant current cathodic polarization was adopted. The density is 1mA / cm 2 , in 0.1M nickel nitrate solution, the electrolytic preparation deposition amount is 0.12mg / cm 2 Nickel hydroxide / titanium mesh electrode. Using 1M KOH solution as the electrolyte, platinum sheet as the counter electrode, and Ag / AgCl as the reference electrode, the three-electrode system was used for cyclic voltammetry scanning and electrochemical capacity testing. It was found that the unreduced titanium mesh has almost no capacity, while the reduced electrode has good electrochemical activity, and its specific capacity is about 2200F / g calculated according to the CV area integral. Calculation basis: where C m (F / g) specific capacity, Q + (C) and Q - (C) are the integrated ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com