Genetically engineered bacterium for producing L-malic acid and construction method and application of genetically engineered bacterium

A malate synthase and gene technology, applied in the fields of biotechnology and fermentation engineering, can solve the problems of easy mycelium formation, many by-products, complicated condition control, etc., and achieve the effect of good industrial application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1, Construction of recombinant bacteria E.coliΔMA6 (pMCS-GA4+pUC-MA3)

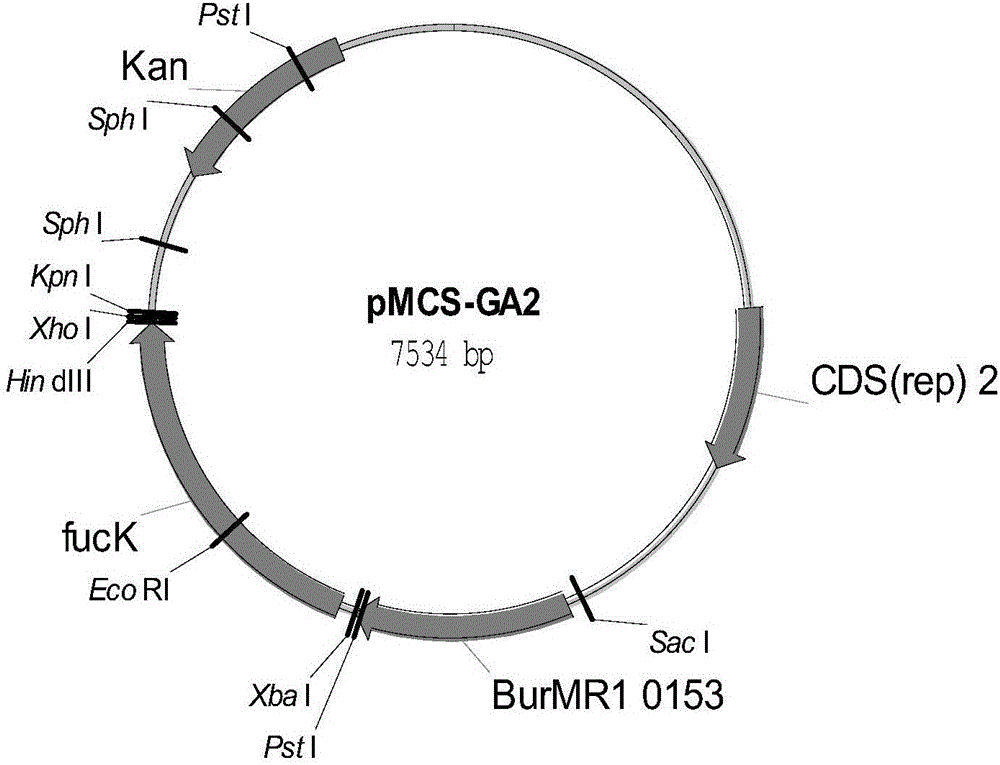

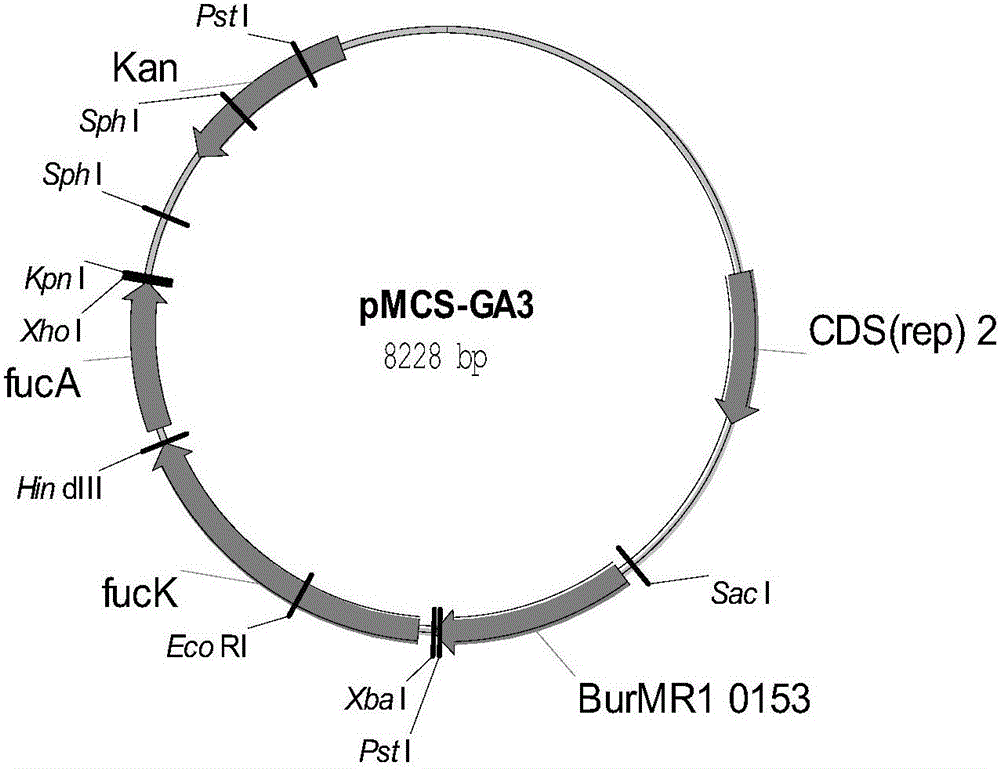

[0065] 1. Construction of recombinant expression vector pMCS-GA4

[0066] 1. The DNA shown in Sequence 1 in the sequence list is artificially synthesized, which contains the BurMR1_0153 expression cassette, the upstream is the SacI site, and the downstream is the XbaI site, wherein the 9th-51st nucleotide is the promoter sequence, and the 70th-942nd Nucleotide is BurMR1_0153 gene sequence.

[0067] 2. The artificially synthesized DNA shown in Sequence 2 in the sequence list contains the fucK expression cassette, the upstream is the XbaI site, and the downstream is the HindIII site, wherein the 9th-51st nucleotide is the promoter sequence, and the 70th-1518th nucleotide Nucleotides are fucK gene sequences.

[0068] 3. The artificially synthesized DNA shown in Sequence 3 in the sequence list contains the fucA expression cassette, the upstream is the HindIII site, and the downstream is the Xh...

Embodiment 2

[0174] Example 2, the application of E.coliΔMA6 (pMCS-GA4+pUC-MA3) in the production of malic acid

[0175] 1. Cultivation of recombinant bacteria E.coliΔMA6 (pMCS-GA4+pUC-MA3) in shake flasks to produce malic acid

[0176] 1. The recombinant bacterium E.coliΔMA6 (pMCS-GA4+pUC-MA3) prepared in Example 1 was cultivated for 16 hours at 37° C. at 200 rpm in LB liquid medium containing ampicillin and kanamycin, as seed liquid.

[0177] 2. The seed solution was inoculated into the MMX1 liquid medium according to the inoculation amount of 4% by volume, and the liquid volume in the 500ml shake flask was 50ml, and cultivated at 37°C and 200rpm for 72h, during which the fermentation broth was collected.

[0178] The preparation method of MMX1 liquid medium: each liter of medium contains 6g xylose, 2g NH 4 Cl, 5.0g (NH 4 ) 2 SO 4 , 6.0g KH 2 PO 4 , 8.214g MOPS, 0.5g NaCl, 1mL trace element solution, 0.1g ampicillin and 0.05g kanamycin, and the rest is water.

[0179] Preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com