A kind of ultraviolet fluorescent material and preparation method thereof

A fluorescent material and ultraviolet technology, applied in the field of ultraviolet fluorescent materials and their preparation, can solve the problems of high cost, long preparation cycle, toxicity of sodium dicyandiamide, etc., and achieve low cost, short preparation cycle and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 4g of melamine and 1.2g of sodium carbonate in a mortar, add absolute ethanol and wet grind to obtain precursor A, put precursor A into an alumina crucible, calcinate in a muffle furnace at 550°C for 2 hours, and cool with the furnace Obtain sample B, grind and dissolve sample B in 50ml of deionized water to obtain a colorless transparent solution, add 50ml of absolute ethanol, the substance precipitates, centrifuge, put it in an oven and dry at 70°C for 12 hours to obtain phosphor powder.

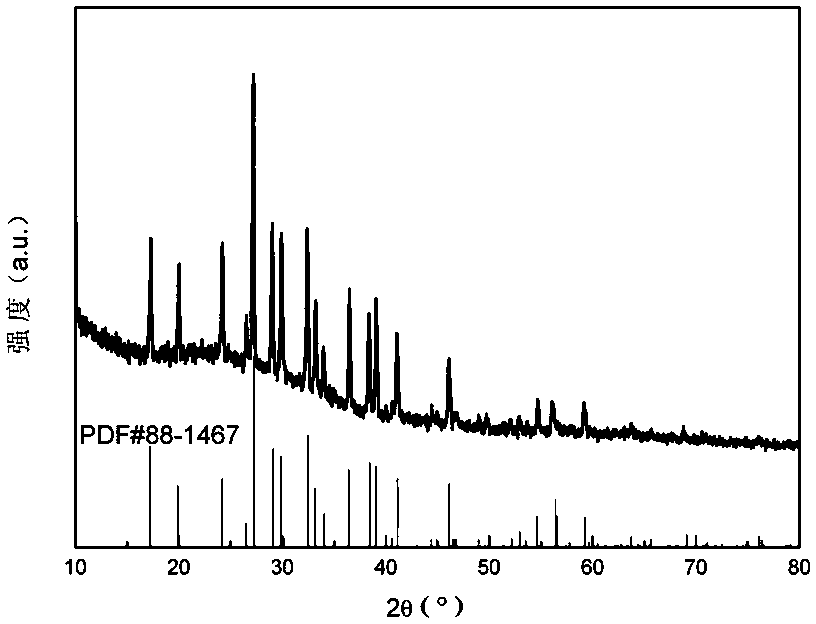

[0018] See attached figure 1 , which is the XRD diffraction pattern of the ultraviolet phosphor powder prepared in this example, from figure 1 It can be seen that the intensity of the diffraction peak is high and sharp, indicating that the synthesized high temperature resistant phosphor has good crystallinity.

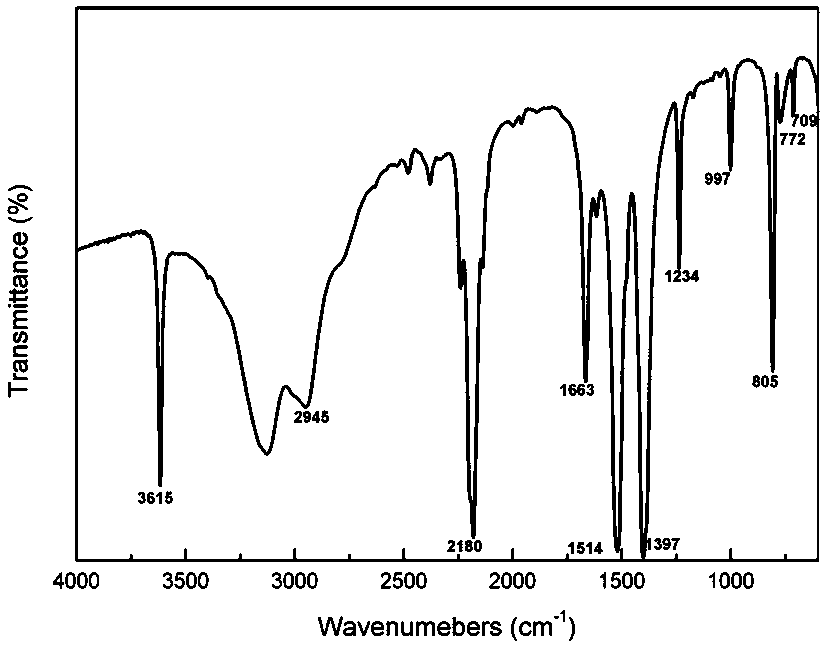

[0019] See attached figure 2 , which is the infrared spectrogram of the ultraviolet fluorescent powder prepared in this example, from figure 2 As can be seen in t...

Embodiment 2

[0022] Weigh 4g of melamine and 1.6g of sodium carbonate in a mortar, add absolute ethanol and wet grind to obtain precursor A, put precursor A into an alumina crucible, calcinate in a muffle furnace at 550°C for 2 hours, and cool with the furnace Obtain sample B, grind and dissolve sample B in 50ml of deionized water to obtain a colorless transparent solution, add 50ml of absolute ethanol, the substance precipitates, centrifuge, put it in an oven and dry at 70°C for 12 hours to obtain phosphor powder.

Embodiment 3

[0024] Weigh 4g of melamine and 2g of sodium carbonate in a mortar, add absolute ethanol and wet grind to obtain precursor A, put precursor A into an alumina crucible, calcinate in a muffle furnace at 550°C for 2 hours, and obtain Sample B, grind and dissolve sample B in 50ml of deionized water to obtain a colorless transparent solution, add 50ml of absolute ethanol, the substance precipitates, centrifuge, put it in an oven for 12 hours at 70°C, and obtain a fluorescent powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com