Boron and benzene ring structure-containing efficient charring flame retardant as well as preparation method and application thereof

A technology of benzene ring structure and flame retardant, which is applied in the field of flame retardant polyester, can solve the problems of fiber material mechanical properties decline, operation and technical difficulties, and high requirements for operators, and achieve strong catalytic carbonization ability, wide application prospects, Raw materials are non-toxic and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

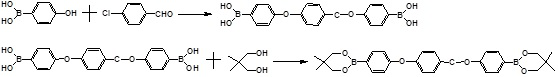

[0045] A kind of preparation method of high-efficiency carbon-forming flame retardant containing boron and benzene ring structure, such as figure 1 shown, including the following steps:

[0046] (1) Dissolve p-hydroxyphenylboronic acid and p-chlorobenzaldehyde in N,N-dimethylformamide / distilled water, and react at 70°C for 60min;

[0047] Among them, the molar ratio of p-hydroxyphenylboronic acid and p-chlorobenzaldehyde is 2:1; the volume ratio of N,N-dimethylformamide and distilled water is 1:1; The dosage ratio of formamide is 1g:1mL;

[0048] (2) Add a certain amount of neopentyl glycol to the reaction system in step (1), raise the temperature to 130 ° C, react for 60 min, and purify by vacuum distillation to obtain a high-efficiency carbon-forming flame retardant containing boron and benzene ring structure ;

[0049] Wherein, the molar ratio of neopentyl glycol and p-hydroxyphenylboronic acid is 1:1; the pressure of vacuum distillation is 35kPa, and the temperature is ...

Embodiment 2

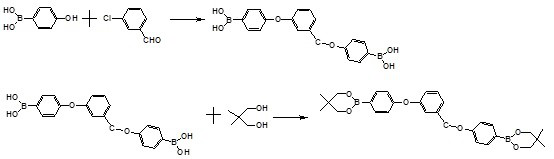

[0053] A kind of preparation method of high-efficiency carbon-forming flame retardant containing boron and benzene ring structure, such as figure 2 shown, including the following steps:

[0054] (1) Dissolve p-hydroxyphenylboronic acid and m-chlorobenzaldehyde in N,N-dimethylformamide / distilled water, and react at 80°C for 50min;

[0055] Among them, the molar ratio of p-hydroxyphenylboronic acid and m-chlorobenzaldehyde is 2.2:1; the volume ratio of N,N-dimethylformamide and distilled water is 2:1; The dosage ratio of formamide is 1g:1.5mL;

[0056] (2) A certain amount of neopentyl glycol is added to the reaction system in step (1), the temperature is raised to 140 ° C, the reaction is carried out for 50 min, and purified by vacuum distillation to obtain a high-efficiency carbon-forming flame retardant containing boron and benzene ring structure ;

[0057] Wherein, the molar ratio of neopentyl glycol to p-hydroxyphenylboronic acid is 1.2:1; the pressure of vacuum distill...

Embodiment 3

[0061] A preparation method of a high-efficiency carbon-forming flame retardant containing boron and a benzene ring structure, specifically comprising the following steps:

[0062] (1) Dissolve p-hydroxyphenylboronic acid and p-chlorobenzaldehyde in N,N-dimethylformamide / distilled water, and react at 75°C for 55min;

[0063] Among them, the molar ratio of p-hydroxyphenylboric acid and p-chlorobenzaldehyde is 2.1:1; the volume ratio of N,N-dimethylformamide and distilled water is 2:1; The dosage ratio of formamide is 1g:1.3mL;

[0064] (2) A certain amount of neopentyl glycol is added to the reaction system in step (1), the temperature is raised to 135 ° C, the reaction is carried out for 55 min, and purified by vacuum distillation to obtain a high-efficiency carbon-forming flame retardant containing boron and benzene ring structure ;

[0065] Wherein, the molar ratio of neopentyl glycol to p-hydroxyphenylboronic acid is 1.1:1; the pressure of vacuum distillation is 40kPa, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com