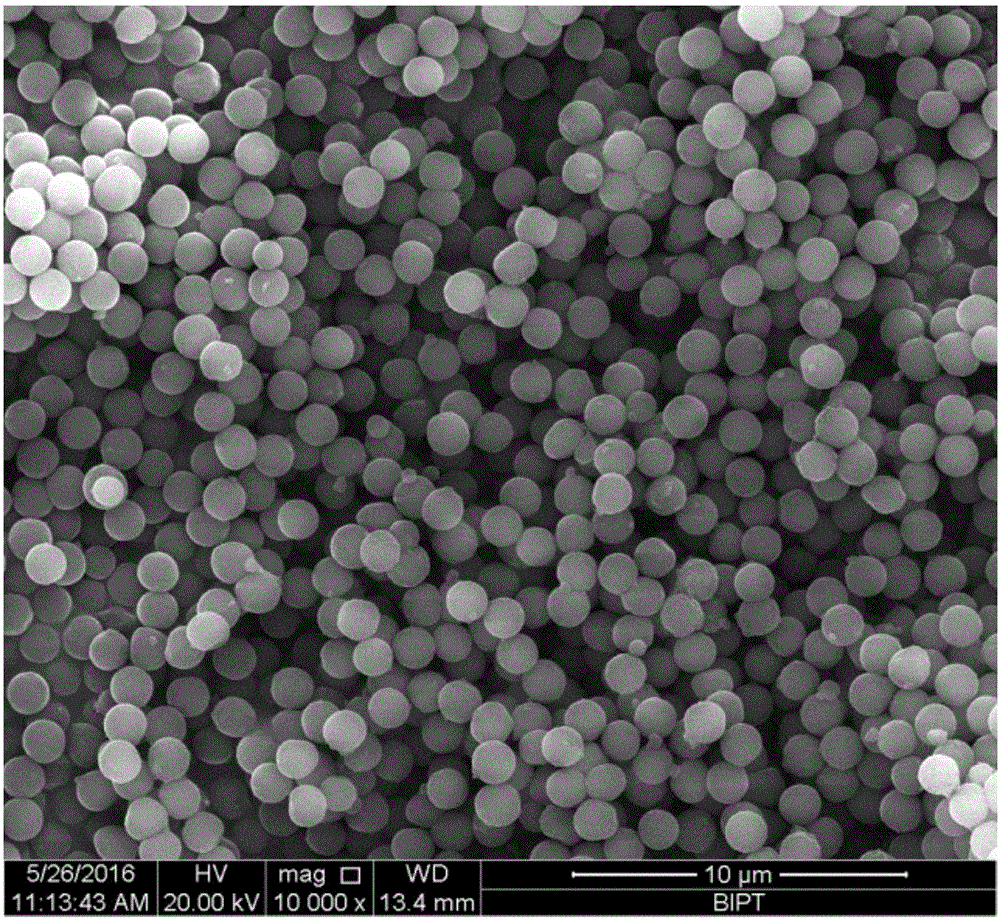

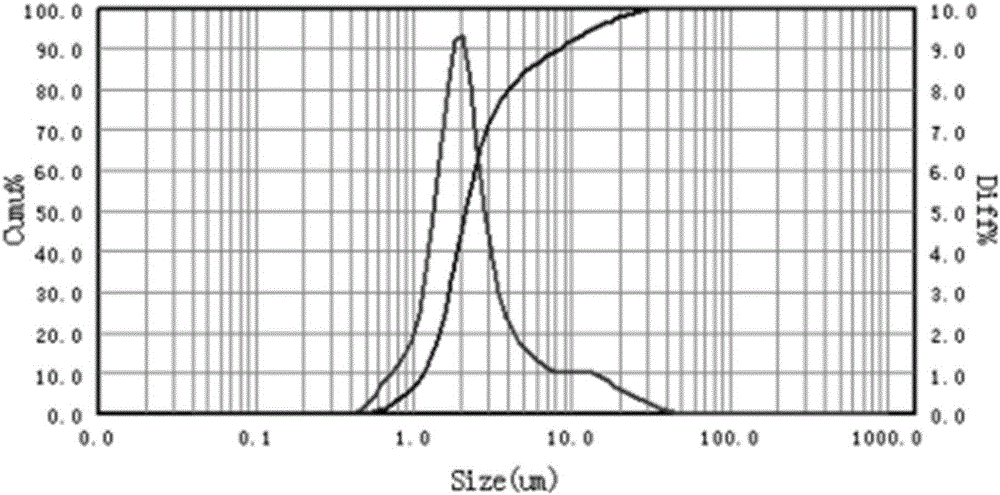

Method for preparing ultrafine cross-linked PMMA (polymethyl methacrylate) microspheres narrow in particle size dispersion

A dispersion and particle size technology, applied in the field of preparation of ultra-fine cross-linked PMMA microspheres, can solve the problems of low cross-linking density of microspheres, cumbersome preparation process, pollution of raw material environment, etc., and achieve good industrial production prospects and preparation process Simple, easy post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The embodiment of the present invention provides a preparation method of ultrafine crosslinked PMMA microspheres with narrow particle size dispersion, comprising the following steps:

[0017] Step 1, add stabilizer, methyl methacrylate MMA and initiator into a container filled with absolute ethanol and deionized water, stir until completely dissolved and heat up to 70°C; the container can be equipped with a condenser or agitator a three-neck flask;

[0018] Step 2, react the reactants in the container of the above step 1 under the action of ultrasonic waves for 1 to 3 hours, add a crosslinking agent for dispersion polymerization, and react for 8 to 24 hours to obtain a PMMA emulsion product; ultrasonic waves help the particle size of the microspheres to be uniform , to achieve a monodisperse effect;

[0019] Step 3, the PMMA emulsion product obtained in the above step 2 is filtered, the filtered product is washed with absolute ethanol and ultrasonically dispersed, and ...

Embodiment 1

[0029] The present embodiment provides a kind of preparation method of the ultrafine cross-linked PMMA microsphere of narrow particle diameter dispersion, comprises the following steps:

[0030] Add 2g of polyvinylpyrrolidone, 6g of methyl methacrylate, 0.2g of azobisisobutyronitrile, 50g of deionized water and 50g of absolute ethanol into a 250ml three-necked flask with a condenser and a stirrer, and adjust the stirring rate to 120r / min, after all the solids are completely dissolved, start to heat up to 70°C, turn on the ultrasonic generator, and react for 1.5 hours; add 0.09 g of ethoxylated trimethylolpropane triacrylate to the reaction solution, and continue to react for 8.5 hours to obtain a white milky Liquid product: filter the obtained emulsion first, wash the filtered product with absolute ethanol and ultrasonically disperse it, and then filter again, repeat filtering, washing, and ultrasonication three times or more to remove excess monomer and dispersant; Vacuum dr...

Embodiment 2

[0032] The present embodiment provides a kind of preparation method of the ultrafine cross-linked PMMA microsphere of narrow particle diameter dispersion, comprises the following steps:

[0033] Add 2g of polyvinylpyrrolidone, 10g of methyl methacrylate, 0.2g of azobisisobutyronitrile, 50g of deionized water and 50g of absolute ethanol into a 250ml three-necked flask with a condenser and a stirrer, and adjust the stirring rate to 120r / min, after all the solids are completely dissolved, start to heat up to 70°C, turn on the ultrasonic generator, and react for 1.5 hours. Add 0.1 g of ethylene glycol dimethacrylate to the reaction solution, and continue to react for 8.5 hours to obtain a white milky liquid product; the obtained emulsion is first filtered, and the filtered product is washed with absolute ethanol and ultrasonically dispersed, and then Filter again. Repeatedly filter, wash, and sonicate three times or more to remove excess monomer and dispersant. Vacuum drying at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com