A method of monolayer array of diatom frustule particles

A technology of diatom frustules and particles, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of low forming efficiency, difficult operation and positioning, and cannot be carried out in large quantities, and achieves the effect of low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

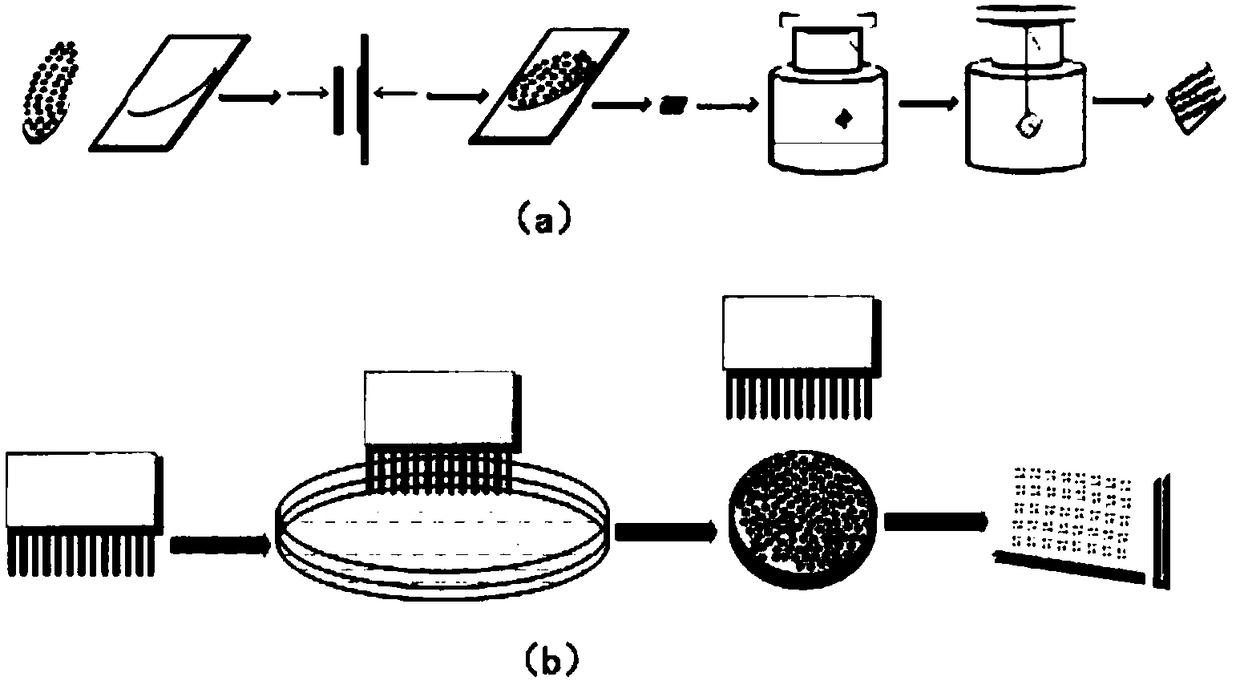

Method used

Image

Examples

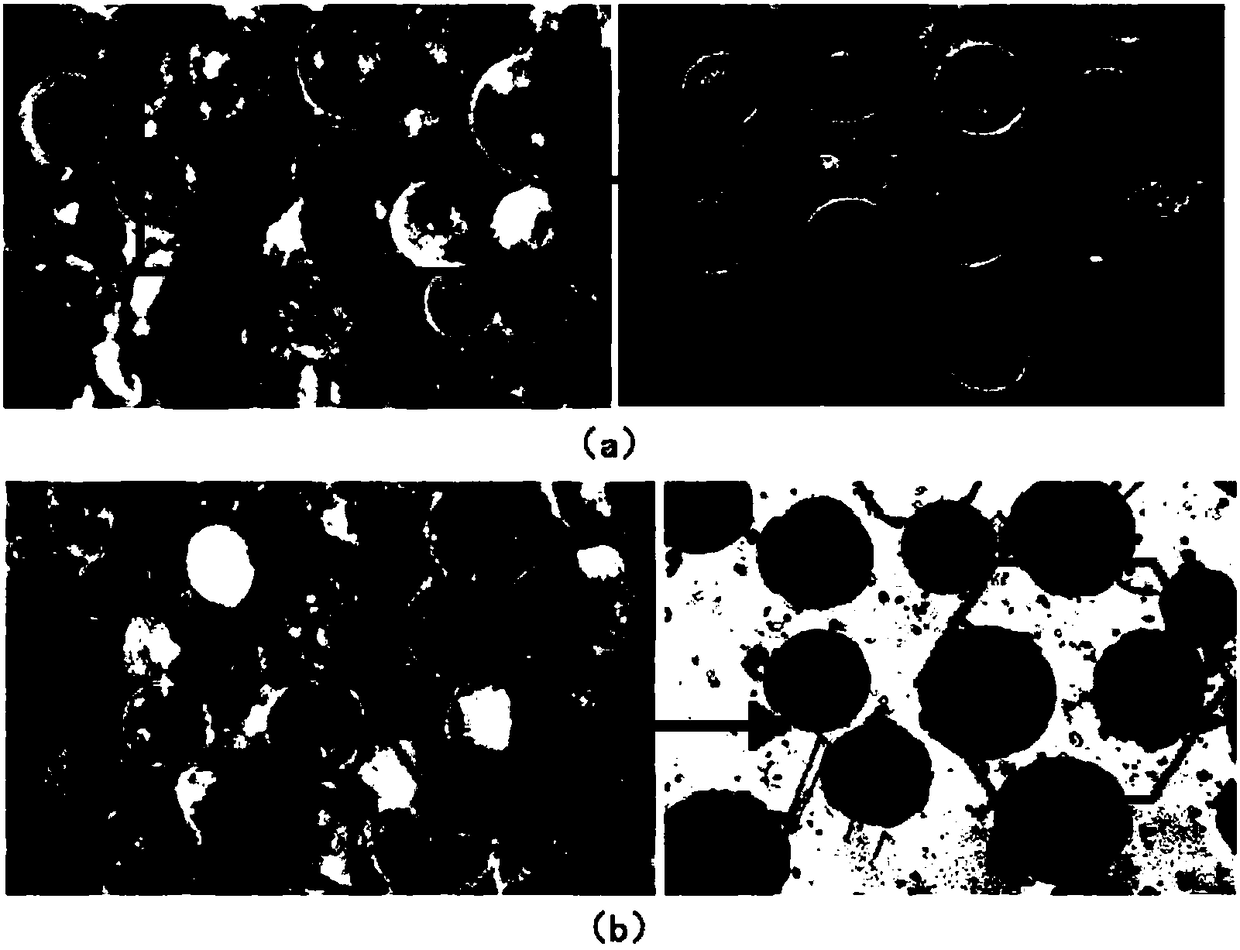

Embodiment 1

[0030] 1) Preparation of diatom frustule particles:

[0031] ① Weigh 10g of diatomite as it is (C289), disperse it in 500mL of natural water, stir it evenly with a glass rod, and vibrate it ultrasonically for 2 minutes to obtain the mixture A; stir again, take 50mL of the mixture A into a measuring cylinder filled with 230mL of water, After settling for 3 minutes, take the upper, middle and lower samples of the measuring cylinder and observe them dropwise. Pour off 100mL of the upper mixed solution, and quickly transfer the middle 100mL to the large-capacity beaker B; The only thing is to pour out the large particles of impurities;

[0032] ②Let the mixture in beaker B stand for 2-3 minutes, remove the clear liquid, disperse the sediment at the bottom with 100mL water, filter with a 350-mesh filter, wash and disperse the filtrate with absolute ethanol, and place it in a blank beaker D middle;

[0033] ③Repeat the above steps until the 500mL mixture A prepared is used up. Th...

Embodiment 2

[0046] 1) Preparation of diatom frustule particles:

[0047] ① Weigh 10g of diatomite as it is (C289), disperse it in 500mL of natural water, stir it evenly with a glass rod, and vibrate it ultrasonically for 2 minutes to obtain the mixture A; stir again, take 50mL of the mixture A into a measuring cylinder filled with 230mL of water, After settling for 3 minutes, take the upper, middle and lower samples of the measuring cylinder and observe them dropwise. Pour off 100mL of the upper mixed solution, and quickly transfer the middle 100mL to the large-capacity beaker B; The only thing is to pour out the large particles of impurities;

[0048] ②Let the mixture in beaker B stand for 2-3 minutes, remove the clear liquid, disperse the sediment at the bottom with 100mL water, filter with a 350-mesh filter, wash and disperse the filtrate with absolute ethanol, and place it in a blank beaker D middle;

[0049] ③Repeat the above steps until the 500mL mixture A prepared is used up. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com