Optical path autocorrelator for distributed optical fiber strain sensing measurement

A distributed optical fiber and optical fiber sensor technology, applied in the field of optical fiber, can solve the problems of increasing stability, deteriorating measurement accuracy, and low utilization rate, and achieve the effect of increasing utilization efficiency and suppressing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is described in more detail below in conjunction with accompanying drawing example:

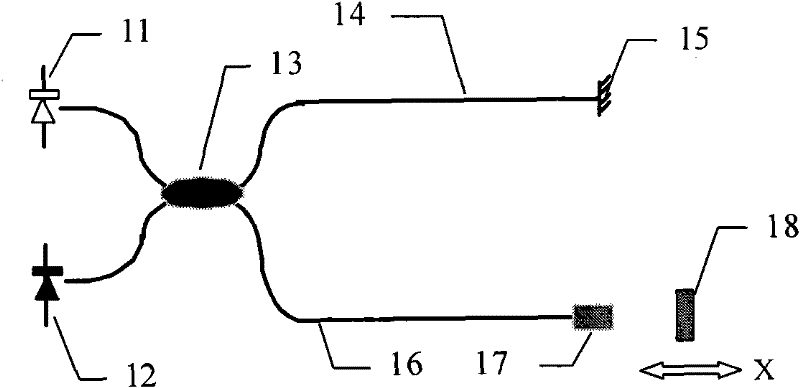

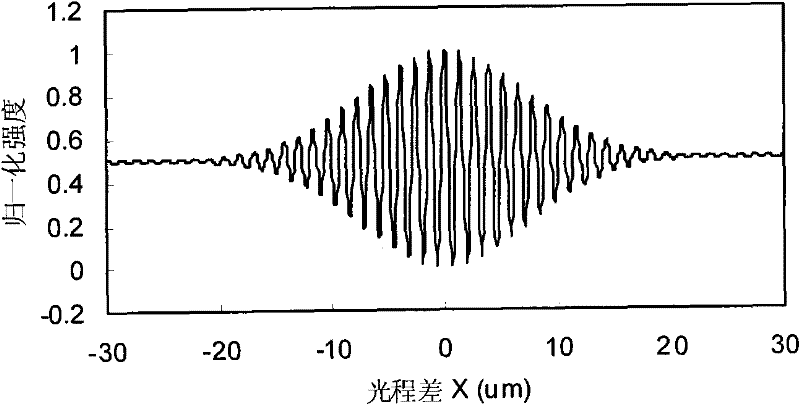

[0055] A scheme for distributed optical fiber strain sensing measurement system based on annular multi-beam generator, such as Figure 5 shown. Depend on Figure 5 It can be seen that the distributed optical fiber white light interference sensor array is composed of a wide-spectrum light source 1, an annular multi-beam generator 2, an optical path autocorrelation detection unit 3, a transmission optical fiber 4, and an optical fiber sensor array 5 connected in sequence from end to end. The annular multi-beam generator 2 is composed of a 2×2 fiber coupler 21, a three-port optical circulator 22, a fiber collimator 23, and a movable optical mirror 24; the optical path autocorrelation detection unit 3 is composed of a three-port optical circulator 31 , a light detector 32 and an interference signal detection and processing unit 33.

[0056] Such as Figure 5 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com