Vehicle-mounted tank made of carbon fiber reinforced composite

A technology of reinforced composite materials and carbon fiber materials, which is applied in the field of vehicle tanks, can solve the problems of poor corrosion resistance of metal tanks, poor economy of long-distance transportation, and heavy weight of metal tanks, so as to reduce poor corrosion resistance and reduce vehicle fuel consumption, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

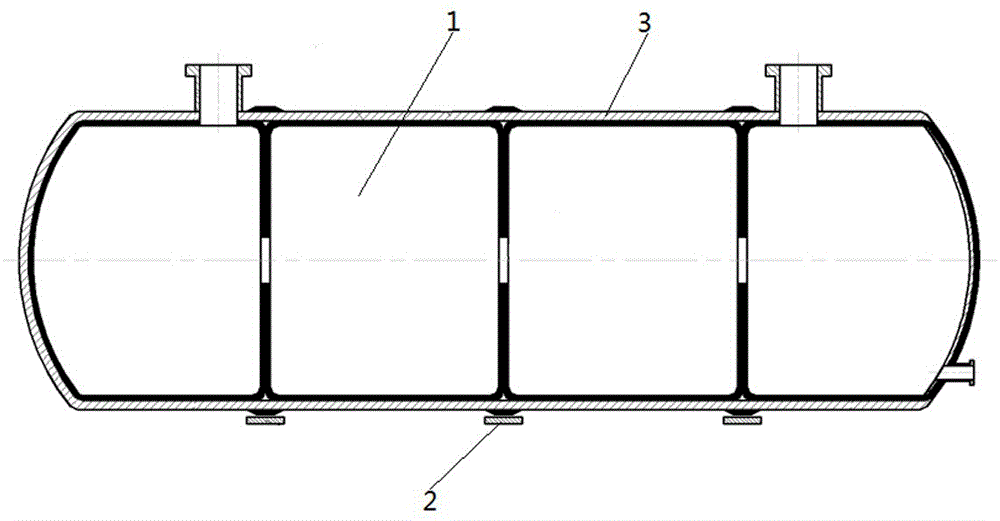

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] A vehicle-mounted tank made of carbon fiber reinforced composite material, comprising a tank cavity 1, a bracket 2 and a structural layer 3, the vehicle-mounted tank is composed of 3 to 6 tank cavities 1, and the tank cavity 1 is divided into an intermediate tank cavity and an end tank cavity Type, the top of the end tank cavity is equipped with a flange; the tank cavity 1 is made of an inner lining layer, and the inner lining layer is made of a rubber material inflatable liner as a mold, and is made by a four-dimensional envelope winding molding process; the tank cavity 1 horizontal The cross-section is a circular or elliptical cylindrical structure. The tank cavities 1 are connected by bolts and adhesives. The tank cavity 1 is covered with a structural layer 3. The structural layer 3 is a glass fiber reinforced thermosetting composite material layer. It adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com