Method and equipment for drying and carbonizing wood integrally on vacuum condition

A technology of carbonization treatment and wood drying, applied in wood drying, wood treatment, wood treatment details, etc., can solve problems such as waste of time, energy, low production efficiency, wood deformation, etc., to reduce energy consumption, improve processing efficiency, air The effect of less content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

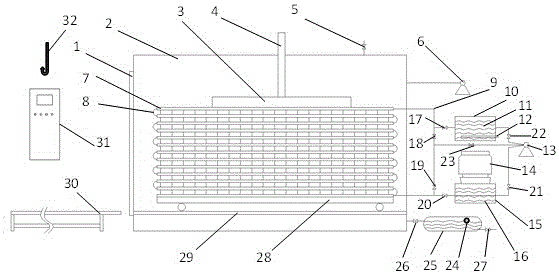

Image

Examples

Embodiment 1

[0036] The wood drying-carbonization treatment integrated treatment method comprises the following steps:

[0037] 1) Timber loading: Process high-moisture-content wood into boards and squares of specified thickness, which require consistent thickness specifications. Pull the trolley out of the drying-carbonization treatment box, and use the lifting device outside the box to lift the hot plate layer by layer. The wood is neatly loaded in a single row between the multi-layer hot plates. After loading, the lifting device is used to lower the heat layer by layer and align up and down. Finally, the trolley is pushed into the processing box. The layer hot plate is pressurized, and the heavy-duty device is pressurized throughout the drying and carbonization process, and finally the equipment airtight door is closed;

[0038] 2) Pre-vacuum treatment: close the inlet valve of the treatment box and the drain valve connected to the drainage box, open the water inlet valve connected to t...

Embodiment 2

[0047] The wood drying-carbonization treatment integrated treatment method comprises the following steps:

[0048] 1) Timber loading: Process high-moisture-content wood into boards and squares of specified thickness, which require consistent thickness specifications. Pull the trolley out of the drying-carbonization treatment box, and use the lifting device outside the box to lift the hot plate layer by layer. The wood is neatly loaded in a single row between the multi-layer hot plates. After loading, the lifting device is used to lower the heat layer by layer and align up and down. Finally, the trolley is pushed into the processing box. The layer hot plate is pressurized, and the heavy-duty device is pressurized throughout the drying and carbonization process, and finally the equipment airtight door is closed;

[0049] 2) Pre-vacuum treatment: close the inlet valve of the treatment box and the drain valve connected to the drainage box, open the water inlet valve connected to t...

Embodiment 3

[0058] The wood drying-carbonization treatment integrated treatment method comprises the following steps:

[0059] 1) Timber loading: Process high-moisture-content wood into boards and squares of specified thickness, which require consistent thickness specifications. Pull the trolley out of the drying-carbonization treatment box, and use the lifting device outside the box to lift the hot plate layer by layer. The wood is neatly loaded in a single row between the multi-layer hot plates. After loading, the lifting device is used to lower the heat layer by layer and align up and down. Finally, the trolley is pushed into the processing box. The layer hot plate is pressurized, and the heavy-duty device is pressurized throughout the drying and carbonization process, and finally the equipment airtight door is closed;

[0060] 2) Pre-vacuum treatment: close the inlet valve of the treatment box and the drain valve connected to the drainage box, open the water inlet valve connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com