Device and method for controlling welding stress and deformation by combining heating with welding and chilling

A welding stress and chilling technology, which is used in the field of devices for controlling welding stress and deformation by combining heating and cooling with welding, and controlling welding stress and deformation by combining heating and cooling with welding, which can solve the problem of large space and volume, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

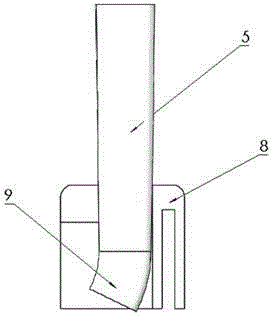

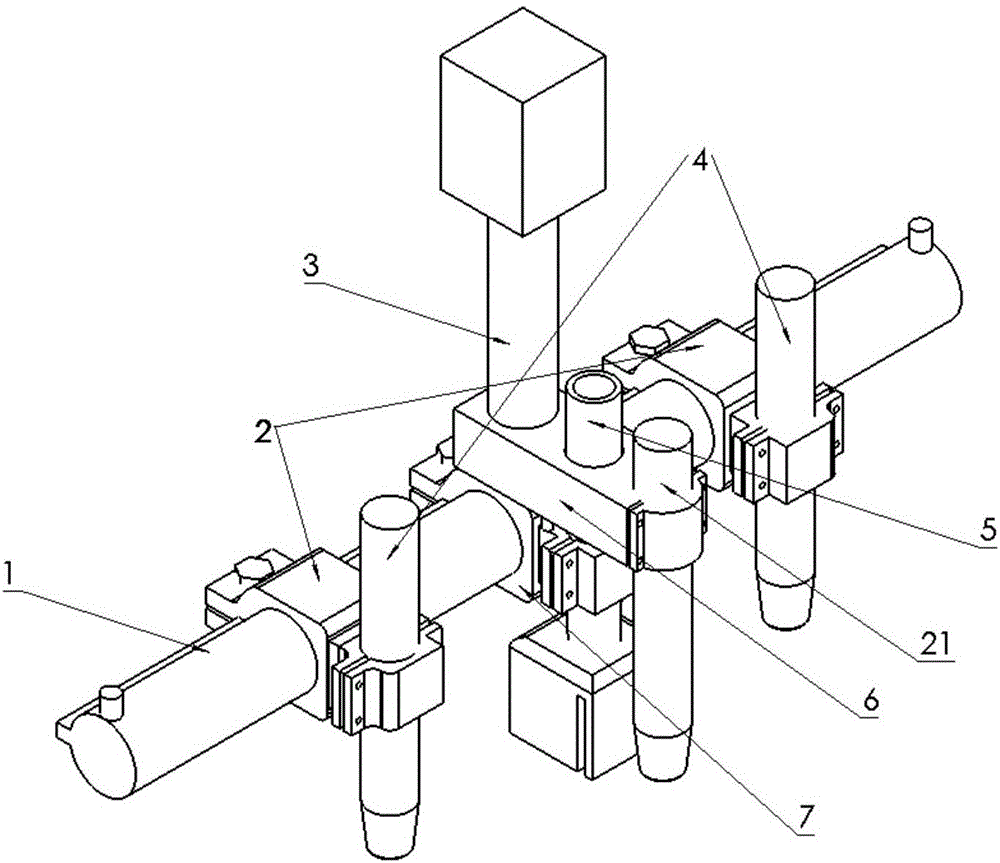

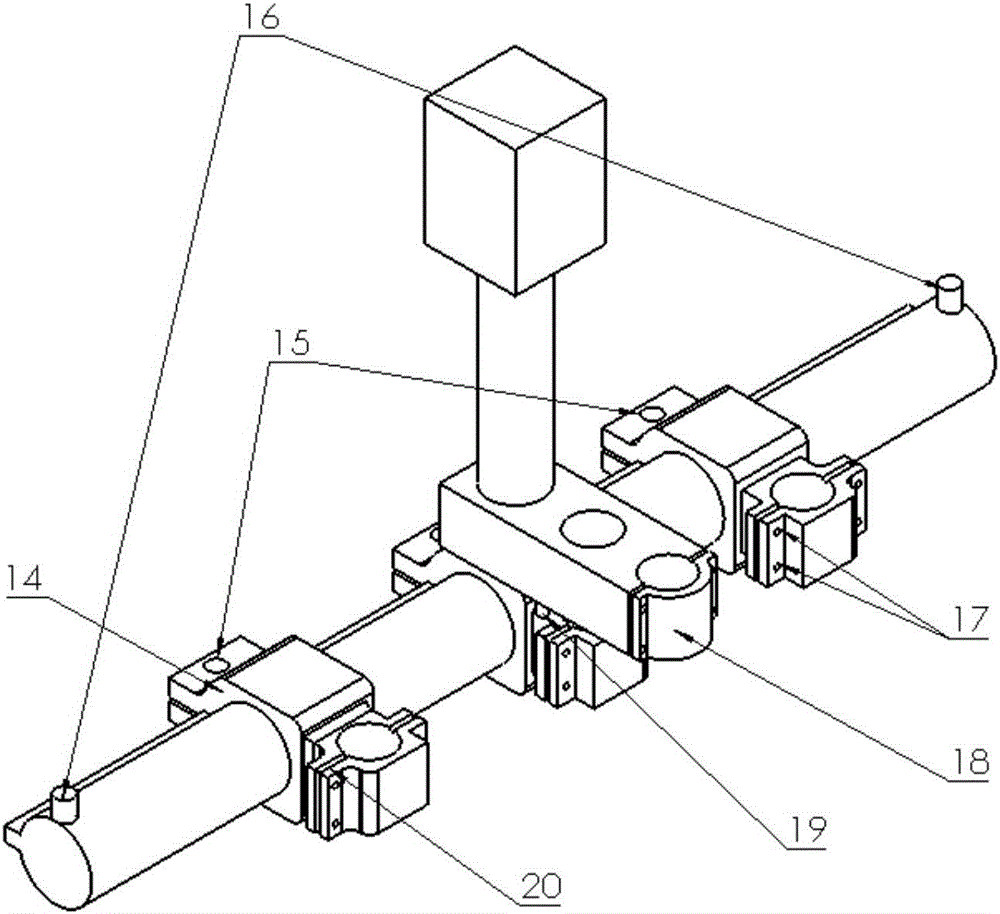

[0023] Such as Figure 1-4 As shown, a device for controlling welding stress and deformation with welding heating and chilling, including a support system and an automatic walking device connected to the support system, a welding system, a heating system and a cooling system. The support system includes a support rod 1 and a vertical The connected vertical rod 3 is provided with a fixed block 7 at the junction of the middle part of the support rod 1 and the root of the vertical rod 3, and multiple fixed blocks 6 are arranged above, and are connected by a pillar 19; a slider is installed on the support rod 1 through a ring sleeve 14 2. Move the slider 2 to adjust the distance from the heat gun 4 to the dry ice nozzle 5. There are screw holes 15 on the ring sleeve 14, which are fastened by bolts 17. There are side plates 20 between the ring sleeves 14; The limit pile 16 is arranged on the side, and the limit pile 16 is fixed on the end of the multiple fixed block 6 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com