Gravure copper gold powder preparation method

A technology of copper-gold powder and metal powder is applied in the field of chemical material preparation technology, which can solve the problems of easy discoloration and poor high temperature resistance, and achieve the effects of not easy discoloration, smooth surface and high production process stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

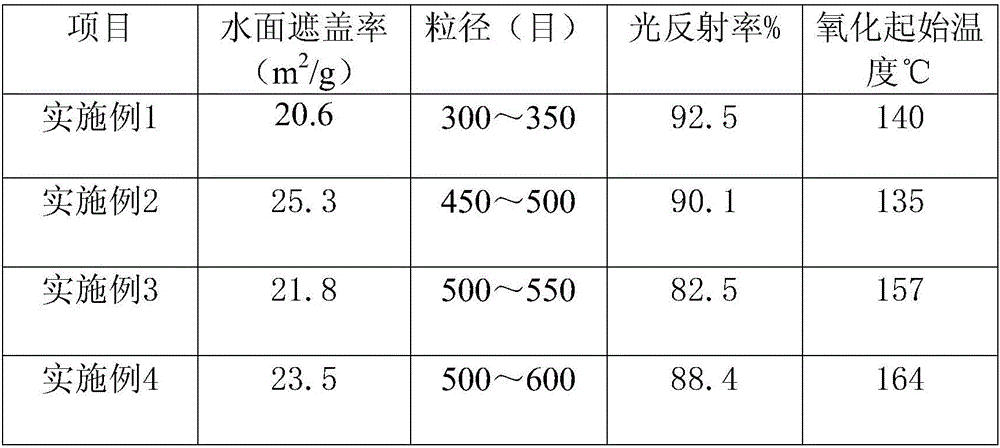

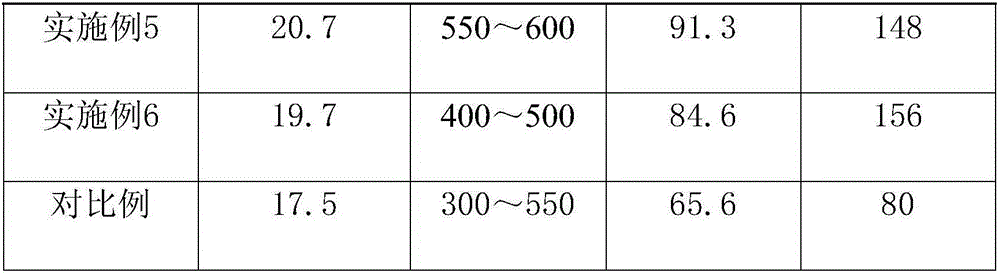

Examples

Embodiment 1

[0028] Step 1: Weigh raw materials, weigh 80kg copper block, 19.5kg zinc block and 0.5kg aluminum block.

[0029] Step 2: The raw material is melted, and antioxidant additives are added to the melting furnace. The antioxidant additives consist of 40g nonylphenol polyoxyethylene ether, 5g propylamine hydrobromide, 2g 2-ethylhexylamine hydrobromide, and 1g oleic acid Composed of triethanolamine and 5g potassium salt of hydrogenated tallow fatty acid; place the zinc block in a furnace and heat it to 450°C to dissolve the zinc block completely, preheat the aluminum block at 500°C and add it to the furnace, and raise the temperature of the furnace to 700 ℃, the aluminum block is completely dissolved, the copper block is preheated at 800 ℃, and then added to the furnace, and the temperature of the furnace is raised to 1200 ℃, so that the copper block is completely dissolved to obtain a molten metal mixture.

[0030] Step 3: Water atomization to produce metal powder, pour the molten ...

Embodiment 2

[0036] Step 1: Weigh raw materials, weigh 70kg copper block, 28kg zinc block and 2kg aluminum block.

[0037] Step 2: The raw material is melted, and antioxidant additives are added to the melting furnace. The antioxidant additives consist of 45g nonylphenol polyoxyethylene ether, 6g propylamine hydrobromide, 3g 2-ethylhexylamine hydrobromide, and 2g oleic acid Composed of triethanolamine and 6g potassium salt of hydrogenated tallow fatty acid; place the zinc block in a furnace and heat it to 460°C to dissolve the zinc block completely, preheat the aluminum block at 520°C and add it to the furnace, and raise the temperature of the furnace to 720°C ℃ to completely dissolve the aluminum block, preheat the copper block at 820°C and add it to the furnace, raise the temperature of the furnace to 1250°C to completely dissolve the copper block to obtain a molten metal mixture.

[0038] Step 3: Water atomization to produce metal powder, pour the molten metal mixture into the leak bag,...

Embodiment 3

[0044] Step 1: Weigh raw materials, weigh 95kg copper block, 4.5kg zinc block and 0.5kg aluminum block.

[0045] Step 2: The raw material is melted, and antioxidant additives are added to the melting furnace. The antioxidant additives are composed of 55g nonylphenol polyoxyethylene ether, 5g propylamine hydrobromide, 4g 2-ethylhexylamine hydrobromide, and 3g oleic acid Composed of triethanolamine and 7g potassium salt of hydrogenated tallow fatty acid; place the zinc block in a furnace and heat it to 470°C to dissolve the zinc block completely, preheat the aluminum block at 520°C and add it to the furnace, and raise the temperature of the furnace to 740 ℃, the aluminum block is completely dissolved, the copper block is preheated at 830 ℃, and then added to the furnace, and the temperature of the furnace is raised to 1290 ℃, so that the copper block is completely dissolved to obtain a molten metal mixture.

[0046] Step 3: Water atomization to produce metal powder, pour the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com