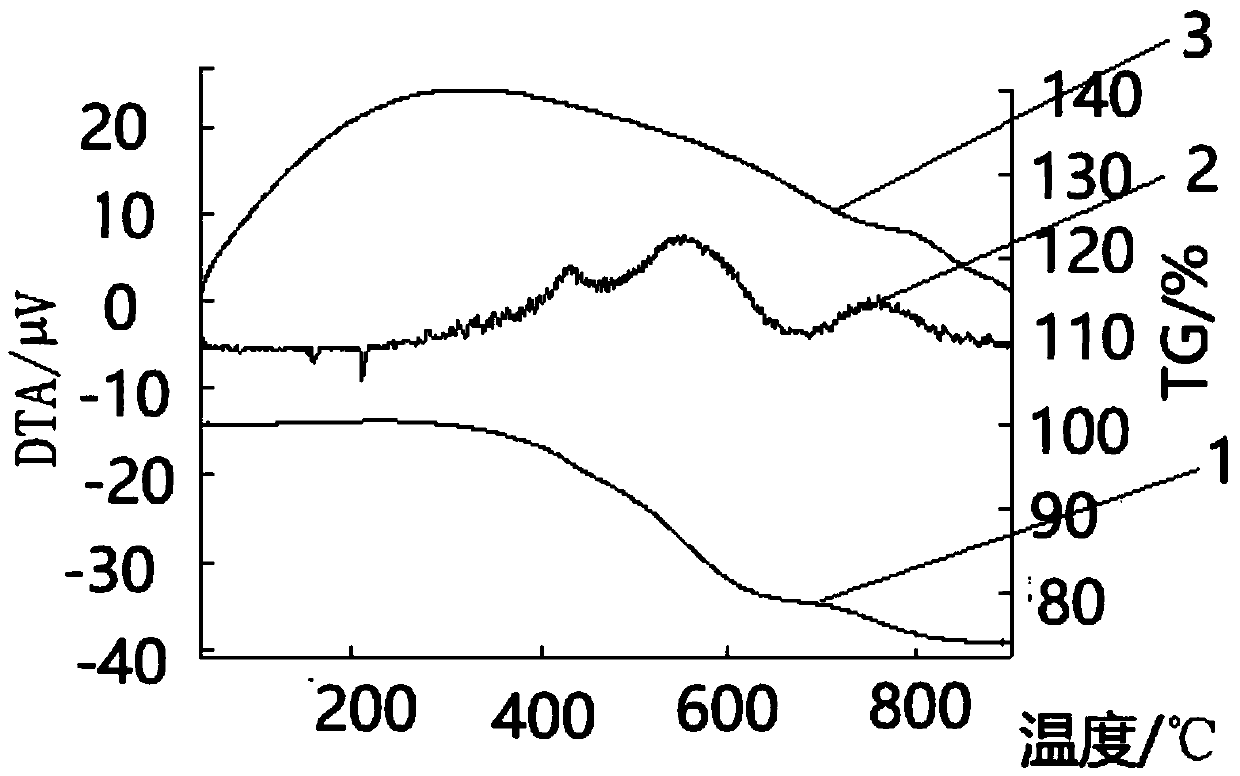

Temperature-resistant coating for coiled material household appliances and preparation method thereof

A home appliance and temperature-resistant technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems that affect product life, coating performance is not up to standard, coating color changes, etc., to achieve good salt spray resistance, excellent decorative performance, metallic feeling strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

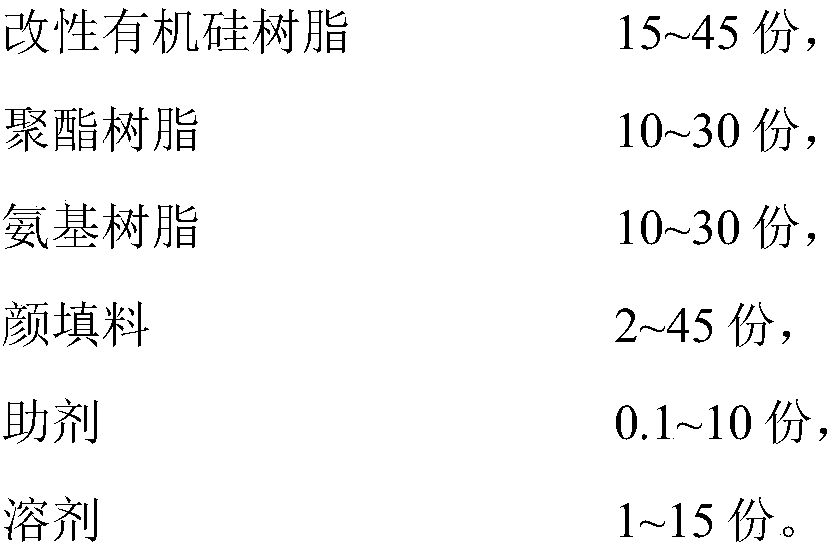

[0049] The temperature-resistant white paint for coiled household appliances includes the following components by weight:

[0050]

[0051] The preparation method of temperature-resistant white paint for coiled household appliances includes the following steps:

[0052] Choose a suitable container and add A, B, C, and D in sequence and stir evenly (15min), add E and F while stirring, and stir evenly; perform sanding, the sanding fineness is 10 microns; after reaching the sanding fineness, stir while While adding G and H, stir evenly and filter; calculate the yield according to the sanded material, and accurately add IL to obtain the temperature-resistant white paint for coiled household appliances.

Embodiment 2

[0054] The temperature-resistant black coating for coiled household appliances includes the following components by weight:

[0055]

[0056]

[0057] The preparation method of temperature-resistant black paint for coiled household appliances includes the following steps:

[0058] Choose a suitable container and add A, B, C, and D in sequence and stir evenly (15min); add E while stirring, and stir evenly; perform sanding, the sanding fineness is 10 microns; after reaching the sanding fineness, add while stirring F, G, stir evenly, filter; calculate the yield according to the sanding material, and accurately add HK to obtain the temperature-resistant black coating for coiled household appliances.

Embodiment 3

[0060] The temperature-resistant metal coating for coiled household appliances includes the following components by weight:

[0061]

[0062] The preparation method of temperature-resistant metal coating for coiled household appliances includes the following steps:

[0063] Choose a suitable container and add A, B, C in sequence, stir evenly (2 hours), so that the aluminum powder is fully soaked; while stirring, add D, E, F, G, and stir evenly; while stirring, add H, I, J, K , Stir evenly to obtain temperature-resistant metal coating for coiled household appliances.

[0064] The performance test of the temperature-resistant coating for coiled household appliances is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com