Method and device for quantum dot synthesis under auxiliary drive of capillary force

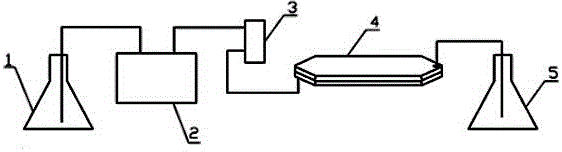

An auxiliary drive and quantum dot technology, which is applied in chemical instruments and methods, nanotechnology, chemical/physical/physical chemical processes, etc., can solve the problem of difficult pumping of precursor solutions into microchannels, and achieve low process cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 64.25mg of cadmium oxide, 0.8ml of oleic acid, 1.0ml of oleylamine, 0.6g of tri-n-octylphosphine oxide and 1ml of 1-octadecene into a beaker and mix them, and heat at 150°C for 1 hour to obtain a cadmium precursor; 39.5mg of selenium powder, 1ml of trioctylphosphine, 1ml of oleylamine and 1ml of 1-octadecene were added to a beaker and mixed, and heated at 100°C for 20 minutes to obtain a selenium precursor; Heat at ℃ for 30 min to obtain a cadmium selenide precursor, which is placed in the precursor liquid reservoir 1 .

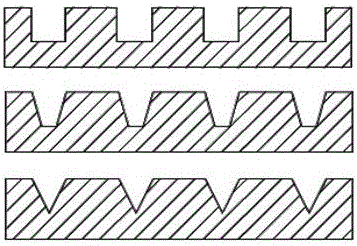

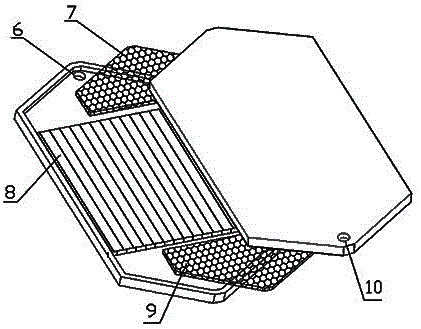

[0034] According to attached figure 1 The device shown is equipped with capillary force-assisted drive to synthesize cadmium selenide quantum dots, using a copper fiber mat with a copper wire diameter of 20 μm and a porosity of 80% as the first capillary liquid-absorbing core 7 and deposited in the inlet and outlet areas of the microchannel reactor 4. The second capillary liquid-absorbing core 9 and the capillary microgroove 8 provided in the reac...

Embodiment 2

[0038] Prepare the cadmium selenide precursor solution according to the method shown in Example 1, place it in the precursor liquid reservoir 1, according to the attached figure 1 The shown assembly capillary force-assisted drive synthesis of cadmium selenide quantum dots uses a copper fiber mat with a copper wire diameter of 20 μm and a porosity of 50% as the first capillary liquid-absorbing core 7 and deposited in the inlet and outlet areas of the microchannel reactor 4. The second capillary liquid-absorbing core 9 and the capillary microgroove 8 provided in the reaction area of the microchannel reactor 4 have a rectangular cross-section, the groove width is 100 μm, the groove depth is 100 μm, and the capillary microgroove spacing is 500 μm.

[0039] When working, use a temperature controller to preheat the microchannel reactor 4 at 250°C for a heating time of 120s; after the preheating is completed, maintain the heating temperature of the microchannel reactor 4 at 250°C; ...

Embodiment 3

[0042] Prepare the cadmium selenide precursor solution according to the method shown in Example 1, place it in the precursor liquid reservoir 1, according to the attached figure 1The shown assembly capillary force-assisted drive synthesis of cadmium selenide quantum dots uses a copper fiber mat with a copper wire diameter of 20 μm and a porosity of 65% as the first capillary liquid-absorbing core 7 and deposited in the inlet and outlet areas of the microchannel reactor 4. The second capillary liquid-absorbing core 9 and the capillary microgroove 8 provided in the reaction area of the microchannel reactor 4 have a rectangular cross-section, the groove width is 50 μm, the groove depth is 50 μm, and the capillary microgroove spacing is 300 μm.

[0043] When working, use a temperature controller to preheat the microchannel reactor 4 at 200°C for a heating time of 250s; after the preheating is completed, maintain the heating temperature of the microchannel reactor 4 at 200°C; The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com