Grading preparation method of coal thermal dissolution substance

A coal-heating and hot-melting technology, applied in the field of coal chemical industry, can solve the problems of limitation, difficult coal hot-melting material classification and extraction, etc., and achieve the effect of low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

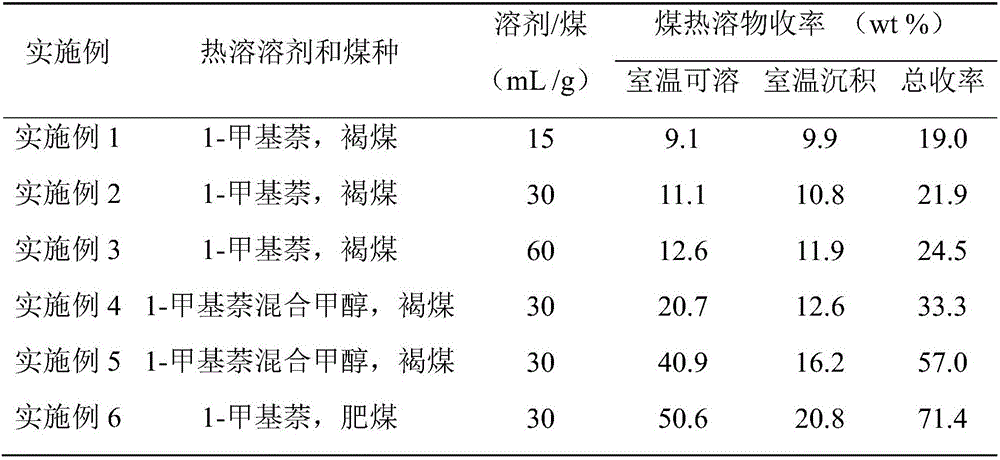

Embodiment 1

[0018] Take by weighing 10.0g lignite, mix with 1-methyl naphthalene solvent according to solvent volume (ml) / coal mass (g) ratio of 15, place 200mL autoclave, use 99.99%N 2 After replacing the air in the autoclave, heat-melt treatment at 360°C and 600r / min for 2h at constant temperature. Cool to room temperature, centrifuge the thermally dissolved coal-organic solvent mixture product to obtain solid residue 1 and organic solution 1, solid residue 1 is washed successively with 1-methylnaphthalene and n-hexane to obtain solid residue 2 and washing liquid, collect the organic solution 1 and the washing liquid, and reclaim the solvent by distillation under reduced pressure, and the solid product obtained is room temperature soluble coal hot-soluble matter, represented by coal hot-soluble matter 1; Amide (DMF) was washed, the organic solution 2 was collected, and the solvent was recovered by distillation under reduced pressure. The solid product obtained was a room temperature dep...

Embodiment 2

[0020] Take by weighing 5.0g lignite, mix with 1-methylnaphthalene solvent at 30 by solvent volume (ml) / coal mass (g) ratio, place 200mL autoclave, use 99.99%N 2 After the air in the autoclave was replaced, it was subjected to constant-temperature heat-melting treatment at 360°C and 600r / min for 3h. Cool to room temperature, centrifuge the thermally dissolved coal-organic solvent mixture product to obtain solid residue 1 and organic solution 1, solid residue 1 is washed successively with 1-methylnaphthalene and n-hexane to obtain solid residue 2 and washing liquid, collect the organic solution 1 and the washing liquid, and reclaim the solvent by distillation under reduced pressure, and the solid product obtained is room temperature soluble coal hot-soluble matter, represented by coal hot-soluble matter 1; Amide (DMF) was washed, the organic solution 2 was collected, and the solvent was recovered by distillation under reduced pressure. The solid product obtained was a room temp...

Embodiment 3

[0022] Take by weighing 2.5g lignite, mix with 1-methylnaphthalene solvent as 60 by solvent volume (ml) / coal mass (g) ratio, place 200mL autoclave, use 99.99%N 2 After the air in the autoclave was replaced, it was subjected to constant-temperature heat-dissolution treatment at 360°C and 600r / min for 4 hours. Cool to room temperature, centrifuge the thermally dissolved coal-organic solvent mixture product to obtain solid residue 1 and organic solution 1, solid residue 1 is washed successively with 1-methylnaphthalene and n-hexane to obtain solid residue 2 and washing liquid, collect the organic solution 1 and the washing liquid, and reclaim the solvent by distillation under reduced pressure, and the solid product obtained is room temperature soluble coal hot-soluble matter, represented by coal hot-soluble matter 1; Amide (DMF) was washed, the organic solution 2 was collected, and the solvent was recovered by distillation under reduced pressure. The solid product obtained was a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com