A kind of preparation method of graphite negative electrode material used in lithium ion battery

A lithium-ion battery, graphite anode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of liquid absorption capacity, poor coating consistency and electrical conductivity, low compaction density of porous structures, and difficult consistency. control and other issues, to achieve the effect of improving the liquid absorption and retention capacity, improving the structural stability and rate performance, and improving the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

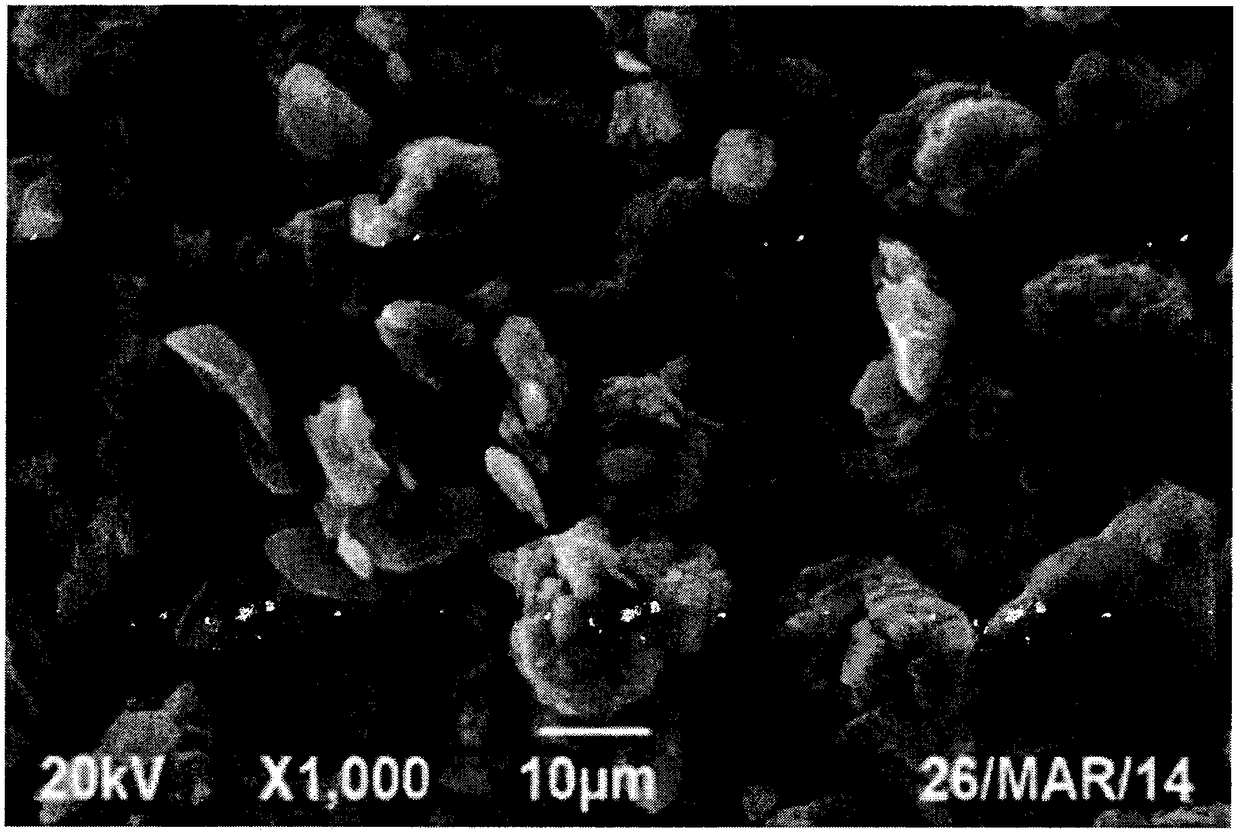

[0024] The preparation method of the present invention comprises three processes of preparation of conductive gel solution, preparation of graphite colloid composite material and preparation of porous graphite negative electrode material, water-based solvent, composite conductive agent and binder are used in the preparation process of conductive gel solution, and the preparation process of graphite colloid composite material Graphite and conductive gel solution are used in the porous graphite negative electrode material. Graphite colloid composite material, active agent and double distilled water are used in the preparation process of porous graphite negative electrode material. The aqueous solvent is deionized water. The composite conductive agent is composed of carbon nanotubes and activated carbon. The agent is LAl32, the graphite is either natural graphite or artificial graphite, and the active agent is any one of KOH and NaOH.

[0025] According to the technical solution, ...

Embodiment 1

[0027] Weigh 6 grams of LAl32 binder, 1 gram of carbon nanotubes, 9 grams of activated carbon and 100 grams of deionized water, mix them together and stir for 2 hours to prepare a conductive adhesive solution. 15 grams of graphite with a particle size of 50 μm was added to the conductive adhesive solution and put into a high-speed disperser to disperse for 10 hours to prepare a graphite colloidal composite material. 100 grams of graphite colloidal composite material and 300 grams of KOH were put into 1500 grams of secondary distilled water and soaked for 5 hours and were prepared into a saturated solution, after which the saturated solution was moved to the carbonization furnace and heated under N 2 Activation was carried out under protection. First, the temperature was raised to 400°C at a constant temperature for 30 minutes at a heating rate of 4°C / min, and then activated at a temperature of 850°C for 80 minutes. 2 After cooling down to room temperature with the furnace unde...

Embodiment 2

[0029] Weigh 8 grams of LAl32 binder, 2 grams of carbon nanotubes, 8 grams of activated carbon and 100 grams of deionized water, mix together and stir for 3 hours to prepare a conductive adhesive solution. 13 grams of graphite with a particle size of 50 μm was added to the conductive adhesive solution and put into a high-speed disperser to disperse for 12 hours to prepare a graphite colloidal composite material. 100 grams of graphite colloidal composite material and 400 grams of NaOH were put into 10000 grams of twice distilled water and soaked for 6 hours and were prepared as a saturated solution, after which the saturated solution was moved to the carbonization furnace and heated under N 2 Activation was carried out under protection. First, the temperature was raised to 300°C at a constant temperature for 40 minutes at a heating rate of 4°C / min, and then activated for 100 minutes when the temperature was raised to 850°C. 2 After cooling down to room temperature with the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com