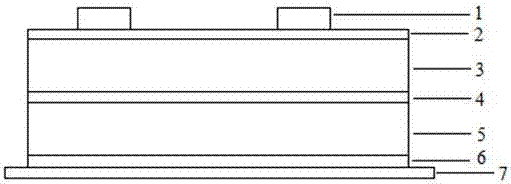

a kind of moo 3 /mos 2 /lif flexible heterojunction solar cell and its preparation method

A technology of solar cells and heterojunctions, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of high production costs, achieve good application prospects, reduce interface defects, and have strong controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

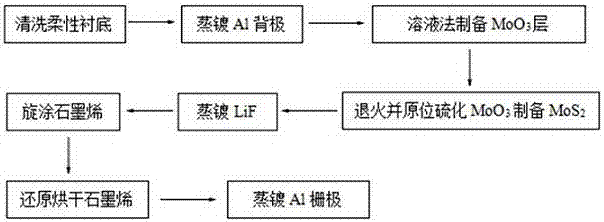

preparation example Construction

[0040] MoO of the present invention 3 / MoS 2 A preparation method for a LiF flexible heterojunction solar cell, comprising the following steps:

[0041] 1. Clean the flexible substrate and dry it. For the above-mentioned cleaning of the flexible substrate, first cut the substrate into the required shape, wash it with detergent, rinse it with third-grade water and first-grade water successively, and then use the first-grade Deionized water, acetone, and ethanol were ultrasonically cleaned for 10 min, and finally rinsed with first-grade deionized water again, dried with high-purity nitrogen, and dried.

[0042] 2 Evaporate Al thin film on flexible substrate by thermal evaporation with vacuum coating machine.

[0043] 3 Preparation of MoO 3 solution, and was spin-coated on the flexible substrate with the Al film evaporated with a colloid machine.

[0044] Preparation of MoO by the above solution method 3 and spin-coated onto flexible substrates evaporated with Al film to for...

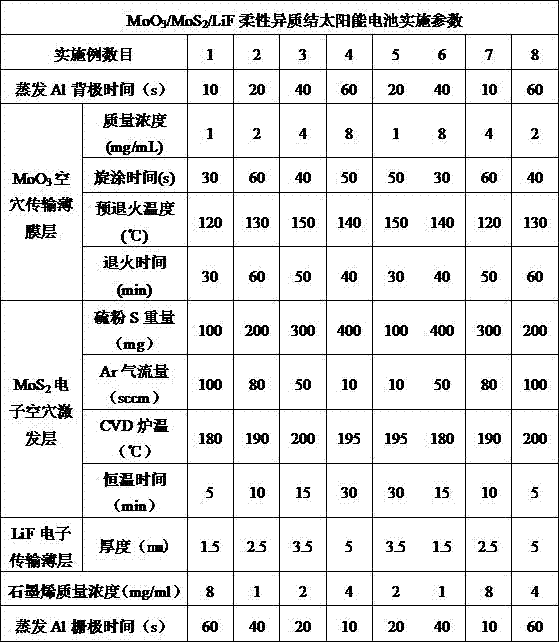

Embodiment 1

[0061] (1) Cleaning polyimide flexible substrate: first put the substrate into a solution containing detergent (such as Liby brand liquid detergent) and soak for 10 minutes, then repeatedly scrub and rinse with water; Sonicate in containers with deionized water, acetone, and alcohol for 10 min respectively; finally put in deionized water to rinse twice, blow dry with a nitrogen gun, and dry in an oven at 80 °C.

[0062] (2) Evaporate a layer of Al on the flexible substrate by thermal radiation heating, voltage 150V, time 10s.

[0063] (3) MoO 3 Solution preparation: 0.4 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 10 ml deionized water, and a small amount of hydrochloric acid solution was added; the solution was heated in air at 80°C for 1 hour; the remaining solution was diluted with deionized water to a solution with a mass concentration of 1 mg / mL.

[0064] (4) In an inert gas-protected gas box, a layer of MoO with a thickness of about 10 nm was thrown on the Al film...

Embodiment 2

[0072] (1) Cleaning polyimide flexible substrate: first put the substrate into a solution containing detergent (such as Liby brand liquid detergent) and soak for 10 minutes, then repeatedly scrub and rinse with water; Sonicate in containers with deionized water, acetone, and alcohol for 10 min respectively; finally put in deionized water to rinse twice, blow dry with a nitrogen gun, and dry in an oven at 80 °C.

[0073] (2) Evaporate a layer of Al on the flexible substrate by thermal radiation heating, voltage 150V, time 20s.

[0074] (3) MoO 3 Solution preparation: 0.4 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 10 ml of deionized water, and a small amount of hydrochloric acid solution was added; the solution was heated in air at 80°C for 1 hour; the remaining solution was diluted with deionized water to a solution with a mass ratio of 2 mg / ml.

[0075] (4) In an inert gas-protected gas box, a layer of MoO with a thickness of about 20 nm was thrown on the Al-coated su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com