High-power LED lamp with pulsating heat pipe type honeycomb radiator and radiating method of high-power LED lamp

A technology of pulsating heat pipes and LED lamps, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve problems such as loss of heat pipes, large thermal resistance ratio, heat difficult to reverse the direction of gravity, etc. , to achieve the effects of reducing the consumption of consumables, high heat transfer density, and reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

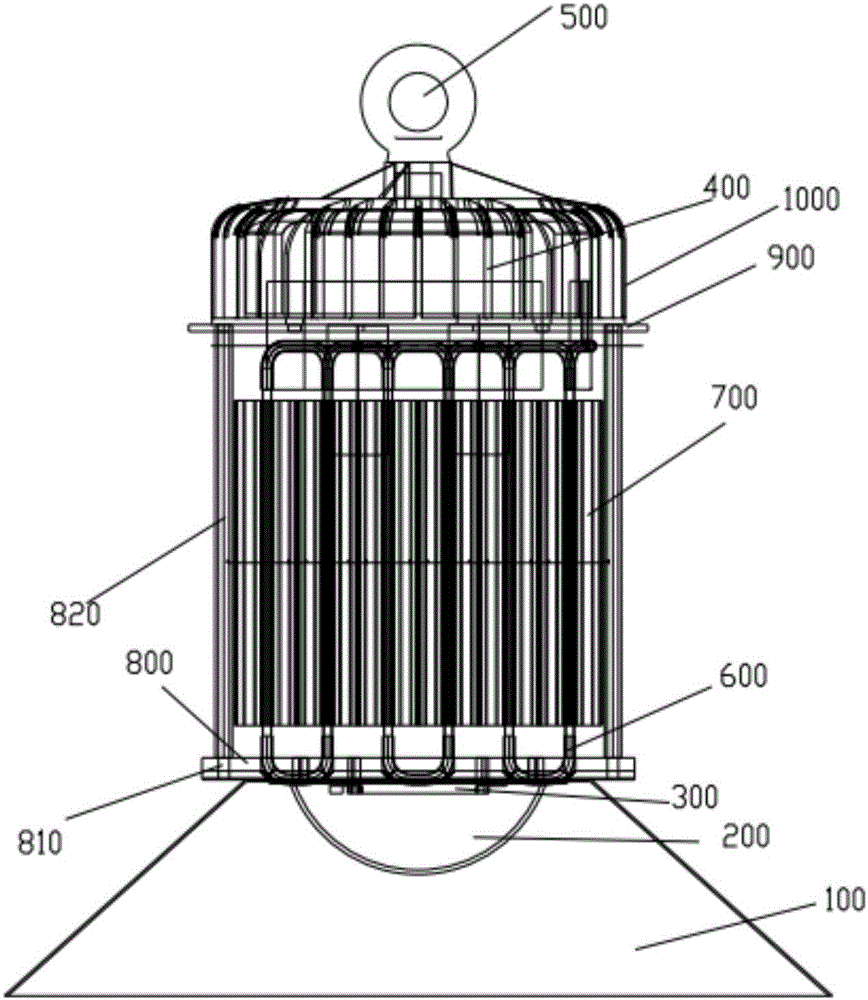

[0031] See Figure 1 to Figure 4 , the invention relates to a pulsating heat pipe type honeycomb radiator

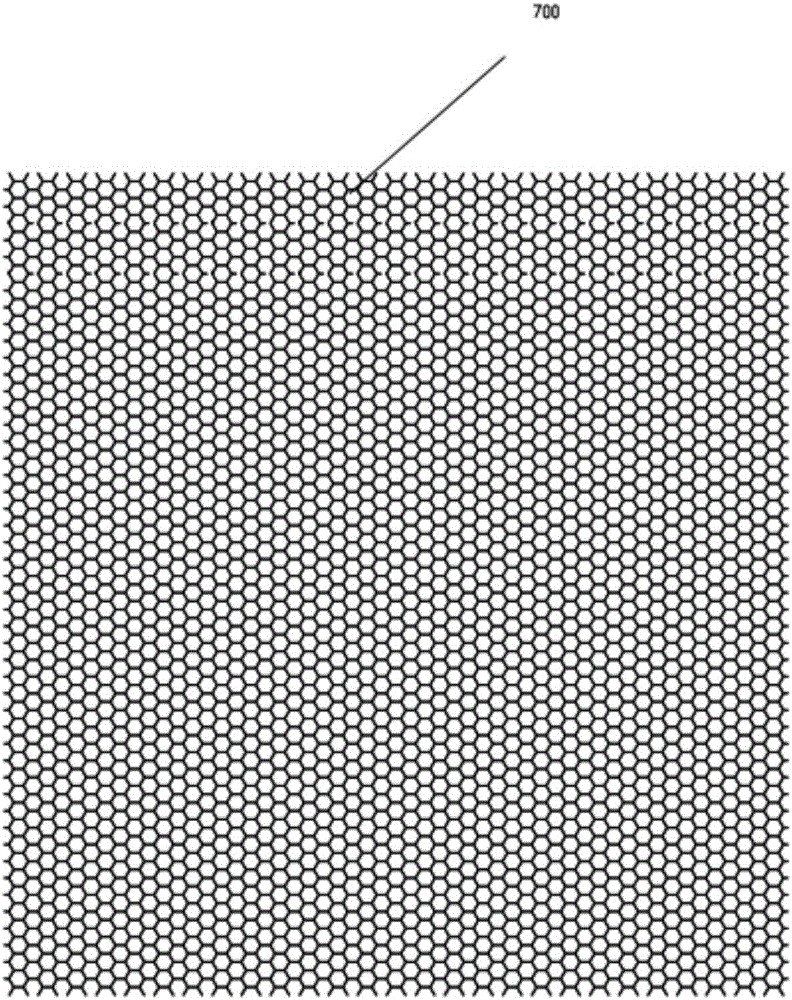

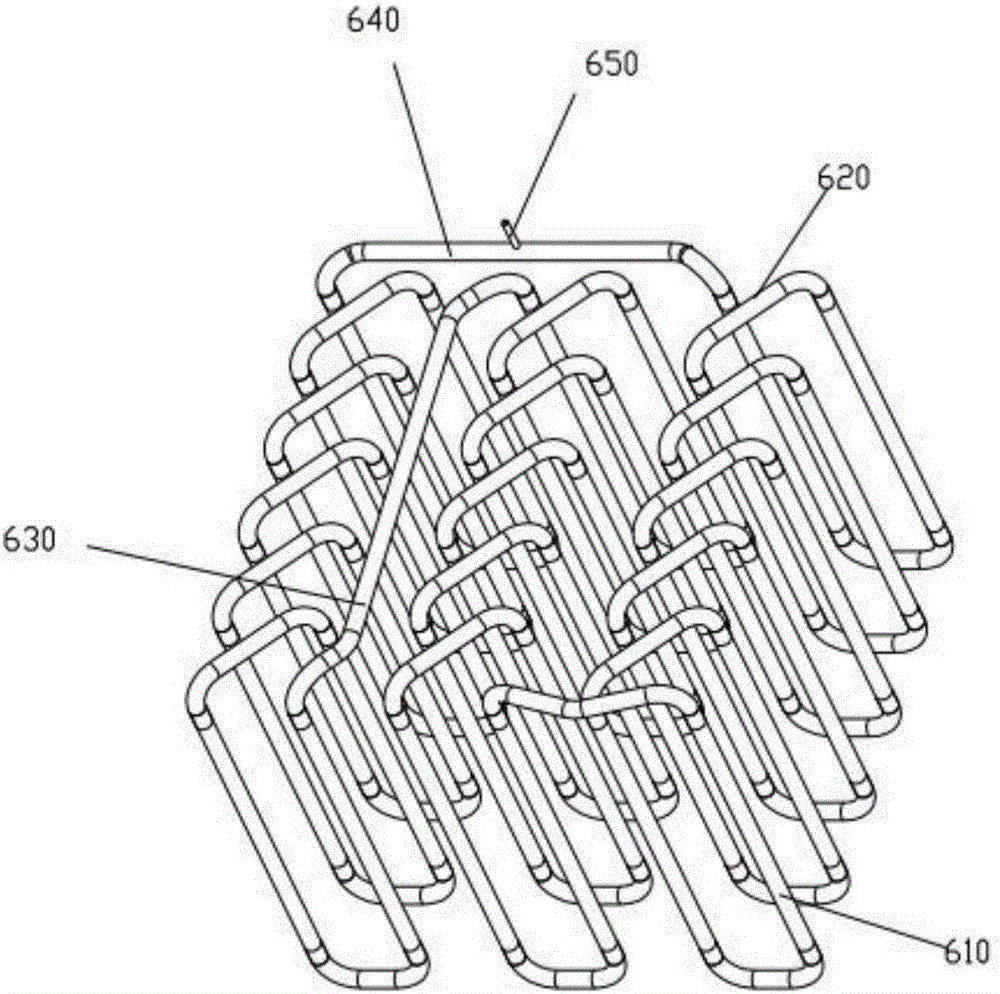

[0032] LED lamp, including LED chip 300, pulsating heat pipe assembly, honeycomb heat sink 700, substrate 800, filling tube 650, the pulsating heat pipe assembly is plugged into the honeycomb heat sink 700 to form a heat dissipation assembly, and the heat dissipation assembly is fixed on the upper side of the substrate 800 , the pulsating heat pipe assembly is a closed circuit; the filling pipe 650 communicates with the closed circuit to fill the closed circuit with fluid working medium; the lower side of the substrate 800 is installed with the LED chip 300 . In this implementation, the base plate 800 is an aluminum alloy bottom plate, the honeycomb heat sink 700 is made of aluminum material, and the working medium is one of ultrapure water, abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com