Production method of spun dyeing mixing ATY (Airjet Texturing Yarn) fiber for vehicle

A technology for pre-spinning coloring and production methods, which is applied in melt spinning, complete sets of equipment for producing artificial threads, textiles and papermaking, etc. The fabric design style is novel and the effect of high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

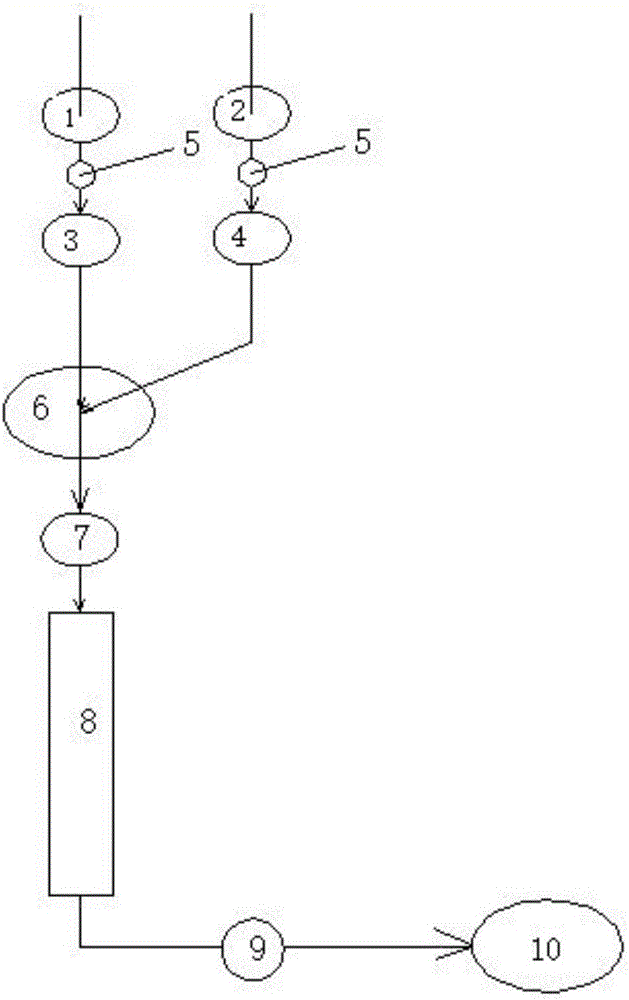

[0030] Such as figure 1 Shown, a kind of production method of pre-spinning colored PET (polyethylene terephthalate) POY fiber A for car with pre-spinning colored PET (polyethylene terephthalate) POY fiber A and ② car with pre-spun pre-spun Colored PET (polyethylene terephthalate) POY fiber B is used as the raw material, among which ① car pre-spinning colored PET (polyethylene terephthalate) POY fiber A is used as air variable leather yarn, ② car Use pre-spinning colored PET (polyethylene terephthalate) POY fiber B as air-changing core yarn, the mass percentage of leather yarn and core yarn is 1:3~3:1, and the first roller 1 and the second roller are used. Roller 2 feeds the yarn, and stretches it through hot-selling 5, and then stretches it through the third roller 3 and the fourth roller 4, the core yarn passes through the first roller 1 and the third roller 3 respectively, and the skin yarn passes through the second roller respectively 2 and the fourth roller 4, enter the a...

Embodiment 2

[0045] A kind of production method of pre-spinning colored PET (polyethylene terephthalate) POY fiber A and ③ pre-spinning colored PET ( Polyethylene terephthalate) POY fiber C is used as raw material, among which ① pre-spinning colored PET (polyethylene terephthalate) POY fiber A for automobile is used as air variable leather yarn, ③ pre-spinning for automobile Colored PET (polyethylene terephthalate) POY fiber C is air-changing core yarn, the mass percentage of leather yarn and core yarn is 1:3~3:1, and the first roller 1 and the second roller 2 are used to feed After being stretched by the hot sale 5, and then stretched by the third roller 3 and the fourth roller 4, the core yarn is passed by the first roller 1 and the third roller 3 respectively, and the skin silk is respectively passed by the second roller 2 and the fourth roller Four rollers 4, entering the air deformation box 6, the air deformation pressure is 12kgf / cm 2 , wherein, the air deformation box is equipped w...

Embodiment 3

[0055] A kind of production method of pre-spinning colored PET (polyethylene terephthalate) POY fiber B and ③ pre-spinning colored PET ( Polyethylene terephthalate) POY fiber C is used as raw material, among which ② pre-spinning colored PET (polyethylene terephthalate) POY fiber B for automobile is used as air variable leather yarn, ③ pre-spinning for automobile Colored PET (polyethylene terephthalate) POY fiber C is air-changing core yarn, the mass percentage of leather yarn and core yarn is 1:3~3:1, and the first roller 1 and the second roller 2 are used to feed After being stretched by the hot sale 5, and then stretched by the third roller 3 and the fourth roller 4, the core yarn is passed by the first roller 1 and the third roller 3 respectively, and the skin silk is respectively passed by the second roller 2 and the fourth roller Four rollers 4, enter the air deformation in the air change box 6, the air deformation pressure is 8kgf / cm 2 , wherein, the air deformation box...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com