QPQ technology for increasing thickness of infiltrated layer on surface of cast duplex stainless steel

A duplex stainless steel and infiltrated layer technology, applied in the field of QPQ, can solve the problems that the infiltrated layer depth is difficult to reach more than 30mm and the infiltrated layer is thin, and achieve the effects of increased wear resistance, dense infiltrated layer structure, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples describe the present invention in more detail, and these examples are only descriptions of the best implementation modes of the present invention, and do not limit the scope of the present invention in any way.

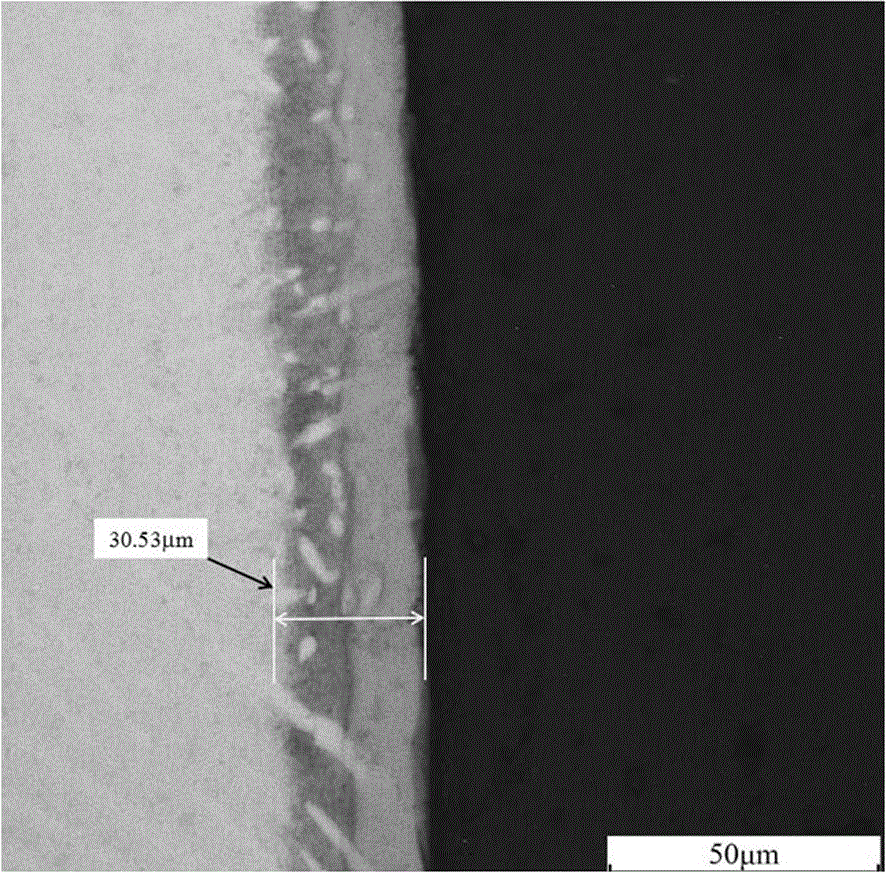

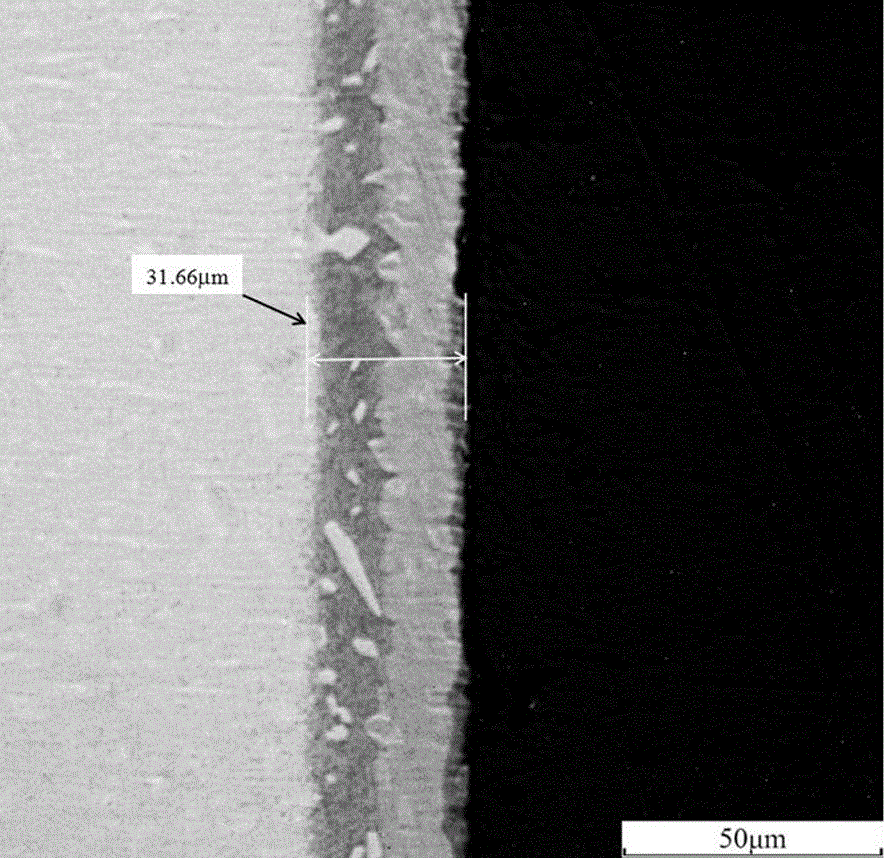

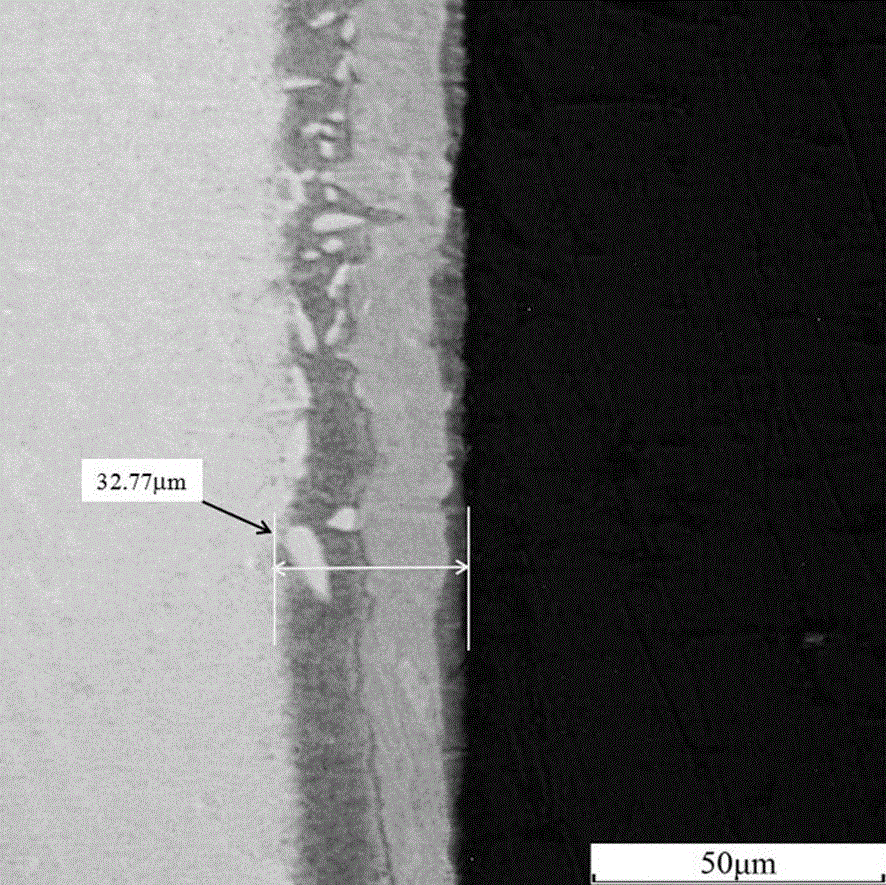

[0025] Example: Melt all the ingredients in an intermediate frequency induction furnace, pour the molten steel after removing oxygen and impurities; process the air-cooled casting into a block sample of 10mm×20mm×50mm, and then do solid solution treatment in a box-type resistance furnace. The solution temperature was set at 1120°C and held for 2 hours; after the solid solution sample was preheated at 400°C for 30 minutes, it was subjected to QPQ treatment to increase the thickness of the infiltrated layer. The technical parameters of QPQ are shown in Table 2; finally, the sample was washed and dried.

[0026] The surface hardness of each sample was measured by a micro-Vickers hardness tester; the wear resistance of each sample was tested b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com