Preparation method of diesel engine DOC/POC cleaning regeneration agent

A regeneration agent and diesel engine technology, applied in the field of cleaning agents, can solve the problems of substandard exhaust gas, environmental pollution, black smoke from exhaust, etc., and achieve the effect of reducing maintenance costs, strong operability, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

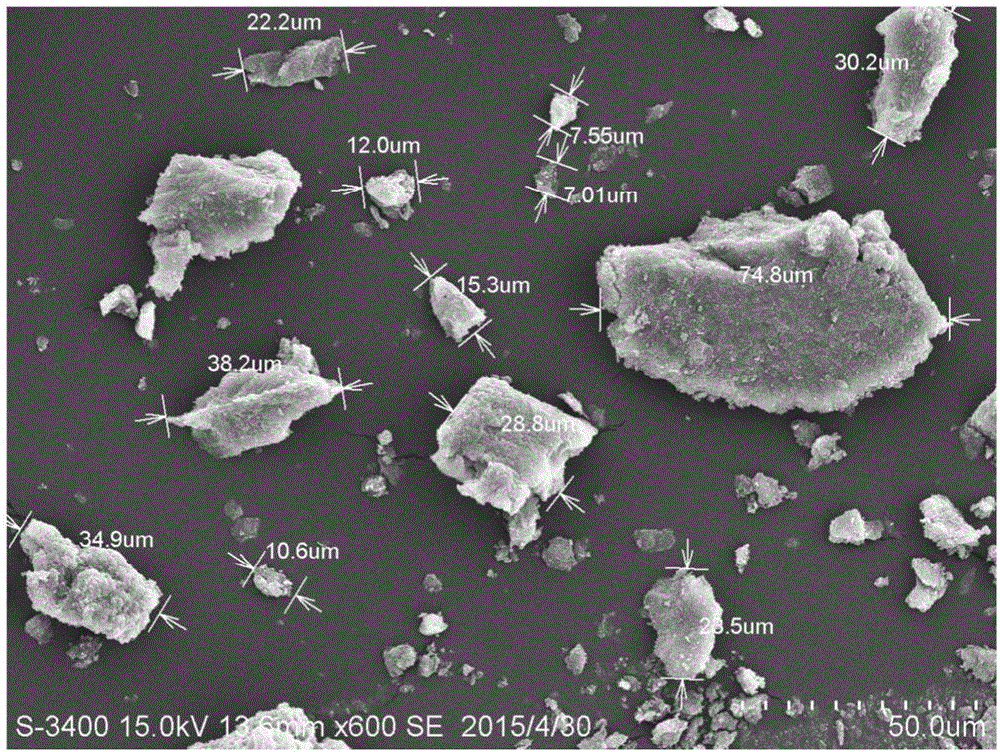

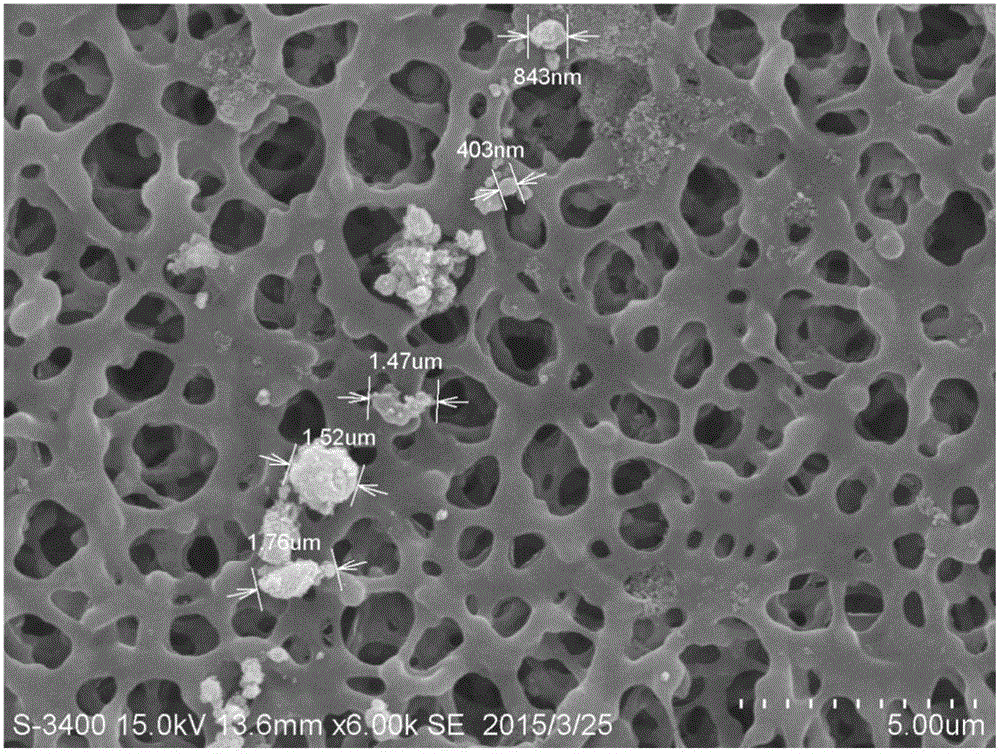

Image

Examples

Embodiment 1

[0014] Raw material composition: solvent (water 56.2%, ethanol 20%) 76.2%, ethylene glycol monobutyl ether 8.4%, polyvinylpyrrolidone 4.1%, mixed fatty alcohol polyoxyethylene ether (JFC) 9.2%, fatty alcohol polyoxyethylene Ether 1.8% and benzotriazole 0.3%.

[0015] Preparation method: Add polyvinyl pyrrolidone to mixed fatty alcohol polyoxyethylene ether (JFC), then add fatty alcohol polyoxyethylene ether, and stir to obtain a uniform mixed solution; add ethylene glycol monobutylene to the prepared mixed solution ether, stir evenly, and then add benzotriazole to obtain a uniform transparent mother liquor; add solvent to the mother liquor, stir slowly to obtain a uniform liquid, and filter to obtain the DOC / POC cleaning and regeneration agent.

[0016] The raw materials used in this embodiment can all be purchased from the market.

[0017] The method of using the diesel engine DOC / POC cleaning regeneration agent of the present invention is as follows: without dismantling the...

Embodiment 2

[0019] Raw material composition: solvent (water 51.3%, ethanol 15%, methanol 5%) 71.3%, dipropylene glycol dimethyl ether 9.1%, triethanolamine 5.9%, polyoxyethylene alkylamine 11.6%, fatty alcohol polyoxyethylene ether 1.8% and polyepoxysuccinic acid 0.3%.

[0020] Preparation method: Add triethanolamine to polyoxyethylene alkylamine, then add fatty alcohol polyoxyethylene ether, and stir to obtain a uniform mixture; add dipropylene glycol dimethyl ether to the prepared mixture, stir evenly, and then add Polyepoxysuccinic acid to obtain a uniform transparent mother liquor; adding solvent to the mother liquor, stirring slowly to obtain a uniform liquid, and filtering to obtain the DOC / POC cleaning and regeneration agent.

Embodiment 3

[0022] Raw material composition: solvent (water 72.5%, ethanol 5%) 77.5%, diethylene glycol methyl ether 7.2%, alkanolamide 3.9%, fatty alcohol polyoxyethylene ether (AEO-9) 8.3%, lauryl amidopropyl Amine oxide 2.8% and benzotriazole 0.3%.

[0023] Preparation method: Add alkanolamide to fatty alcohol polyoxyethylene ether (AEO-9), then add lauramide propylamine oxide, stir to obtain a uniform mixture; add diethylene glycol to the prepared mixture Diethyl ether, stir evenly, and then add benzotriazole to obtain a uniform transparent mother liquid; add solvent to the mother liquid, stir slowly to obtain a uniform liquid, and filter to obtain the DOC / POC cleaning and regeneration agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com