Waterproof adhesive for ceramic tiles

A ceramic tile adhesive and waterproof technology, which is applied in the field of tile adhesive waterproofing, can solve the problems of the flexibility of the waterproof layer, the decline of the waterproof performance of the adhesive force, and the influence of wall decoration and living comfort, and achieve the effect of high waterproof and impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

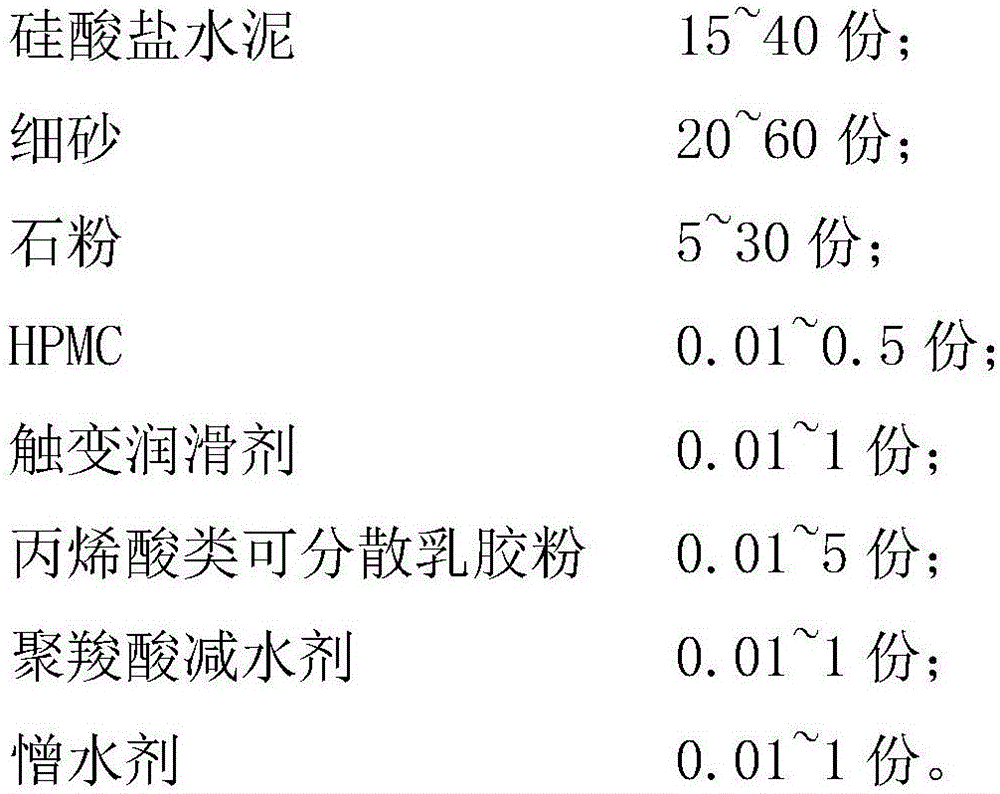

[0027] Each component of tile layer adhesive of the present invention is as follows in parts by weight:

[0028]

[0029] The particle size of the fine sand is ≤0.5mm.

[0030] The particle size of the stone powder is ≤0.075mm.

[0031] The HPMC is medium and low viscosity HPMC.

[0032] The using method of the present invention is as follows:

[0033] (1) Stir and mix, pour clean water into the electric mixer, then put the mixed powder of the above formula into clear water and stir into a paste, the mass percentage of water and mixed powder is: 1:5;

[0034] (2) Stir evenly. After the stirring is completed, it must be placed still. After 10-15 minutes, stir it slightly before using it;

[0035] (3) For construction, select the size of the toothed scraper according to the flatness of the working surface and the degree of convexity and concaveness on the back of the tile, and use the scraper to evenly apply the tile adhesive to the working surface, each coating is about 1...

Embodiment 2

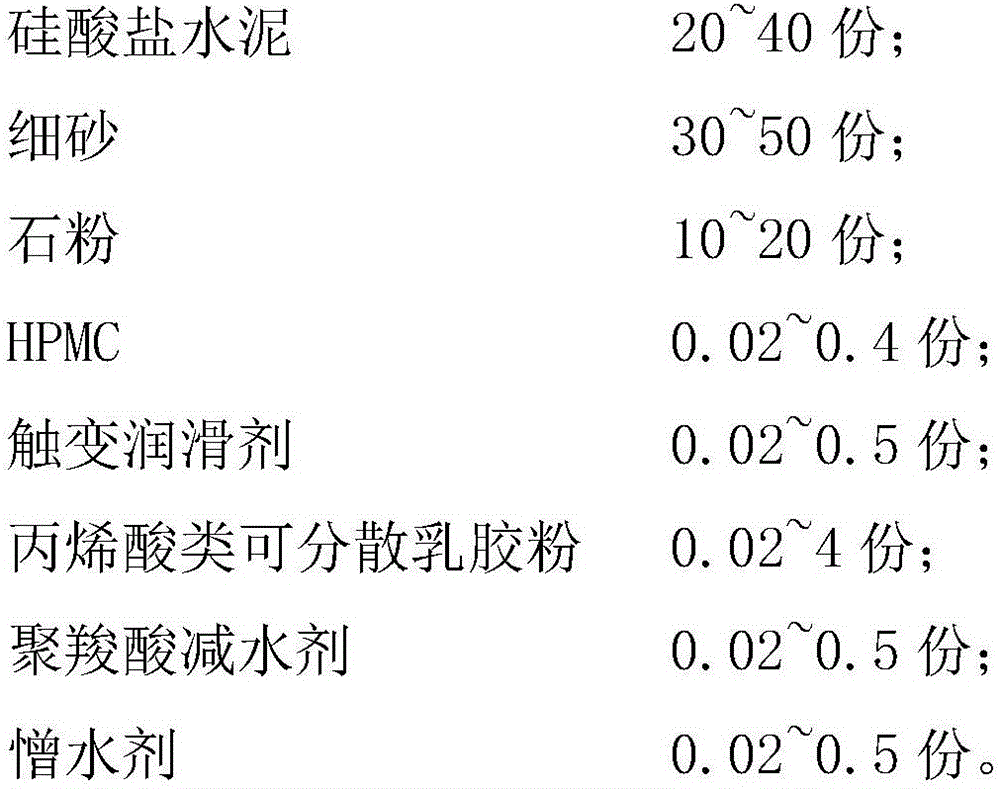

[0038] Each component of tile layer adhesive of the present invention is as follows in parts by weight:

[0039]

[0040] The particle size of the fine sand is ≤0.5mm.

[0041] The particle size of the stone powder is ≤0.075mm.

[0042] The HPMC is medium and low viscosity HPMC.

[0043] Refer to Example 1 for the method of use.

Embodiment 3

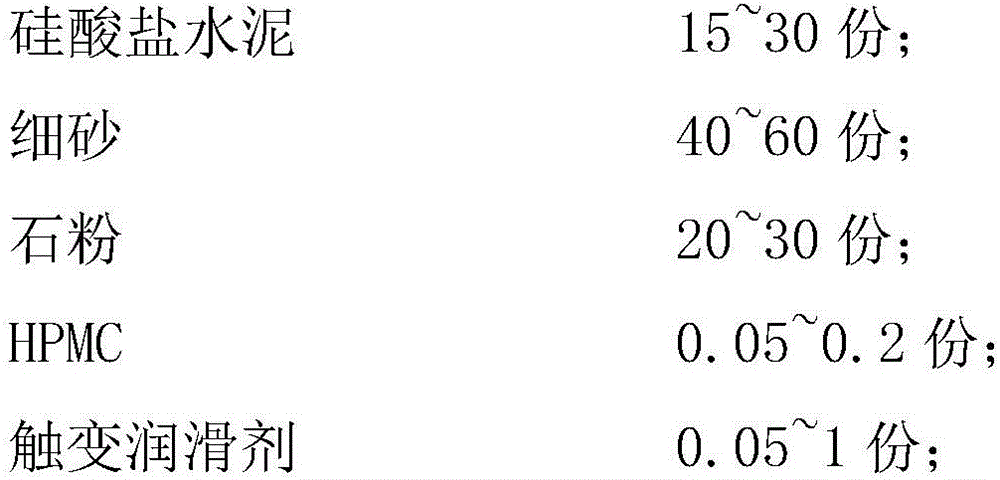

[0045] Each component of tile layer adhesive of the present invention is as follows in parts by weight:

[0046]

[0047] The particle size of the fine sand is ≤0.5mm.

[0048] The particle size of the stone powder is ≤0.075mm.

[0049] The HPMC is medium and low viscosity HPMC.

[0050] Refer to Example 1 for the method of use.

[0051] The above three embodiments can all meet the requirements of JC / T 547-2005 "Ceramic Wall and Floor Tile Adhesives", and also meet the requirements of JC / T 984-2011 "Polymer Cement Waterproof Mortar", water absorption ≤ 6.0% and test piece 28d resistance Osmotic pressure ≥ 1.0MPa requirements.

[0052] The anti-seepage pressure requirement of the waterproof tile adhesive of the present invention is ≥1.0MPa. The most commonly used JS mud-based waterproof coating in the market has no requirement for anti-seepage pressure, Type I requires ≥0.6MPa, Type III requires ≥0.8MPa, so this The invented waterproof tile adhesive is especially suitabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Impermeability pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com