A kind of preparation method of oriented polylactic acid profile

A polylactic acid and orientation technology, applied in the field of producing oriented polylactic acid profiles, can solve problems such as poor interface matching, achieve low equipment requirements, excellent mechanical properties, and expand the effect of practical application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

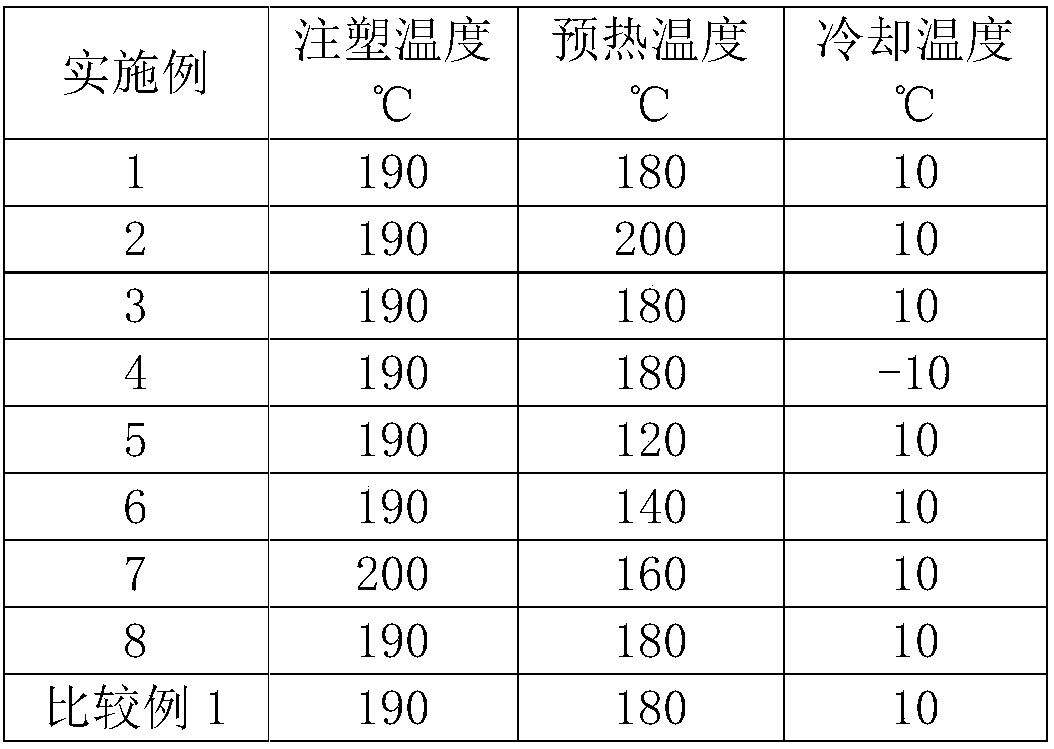

[0026] A preparation method of oriented polylactic acid profile, according to the following steps:

[0027] [1]. Vacuum-dry the L-polylactic acid fully before use.

[0028] [2]. After setting all the parameters of the injection molding machine, preheat it; after the preheating is completed, add the dried polylactic acid to start the injection molding process.

[0029] [3]. Heat the extrusion mold to 180°C. After stabilization, put the product of step [2] into the cavity of the mold while it is still hot.

[0030] [4]. Start the equipment and extrude the obtained product into the molding cavity preheated to 120°C to prepare polylactic acid profiles in an oriented state.

[0031] [5]. After the extrusion is completed, the polylactic acid profile is rapidly cooled and quenched together with the molding cavity to obtain the final polylactic acid profile. Under the same conditions as other production conditions, polylactic acid with a specific rotation of -150° to -160° and a vis...

Embodiment B

[0040] A preparation method of oriented polylactic acid profile, according to the following steps:

[0041] [1]. L-polylactic acid with a crystallinity of 8.5% is placed in a vacuum environment and fully dried before use.

[0042] [2]. Heat the polylactic acid processing mold to 200°C and keep the temperature constant. After the preheating is completed, put the polylactic acid particles into the mold and heat up and pressurize in a vacuum environment.

[0043] [3]. Heat the polylactic acid profile forming mold to 180°C and keep the temperature constant, and put the obtained product into the mold while it is still hot.

[0044] [4]. Start the equipment for forging, the forging pressure is 15MPa, and keep the pressure for 20s.

[0045] [5]. After the pressure holding is completed, quickly quench the polylactic acid profile under the pressure holding condition, and the quenching time is 10 minutes.

[0046] [6]. After the quenching is completed, the polylactic acid profile can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com