Ore smashing device

A technology of ore crushing and crushing roller, which is applied in the field of mining machinery, can solve the problems of clogging the crushing shaft, affecting the quality of ore crushing, and poor crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

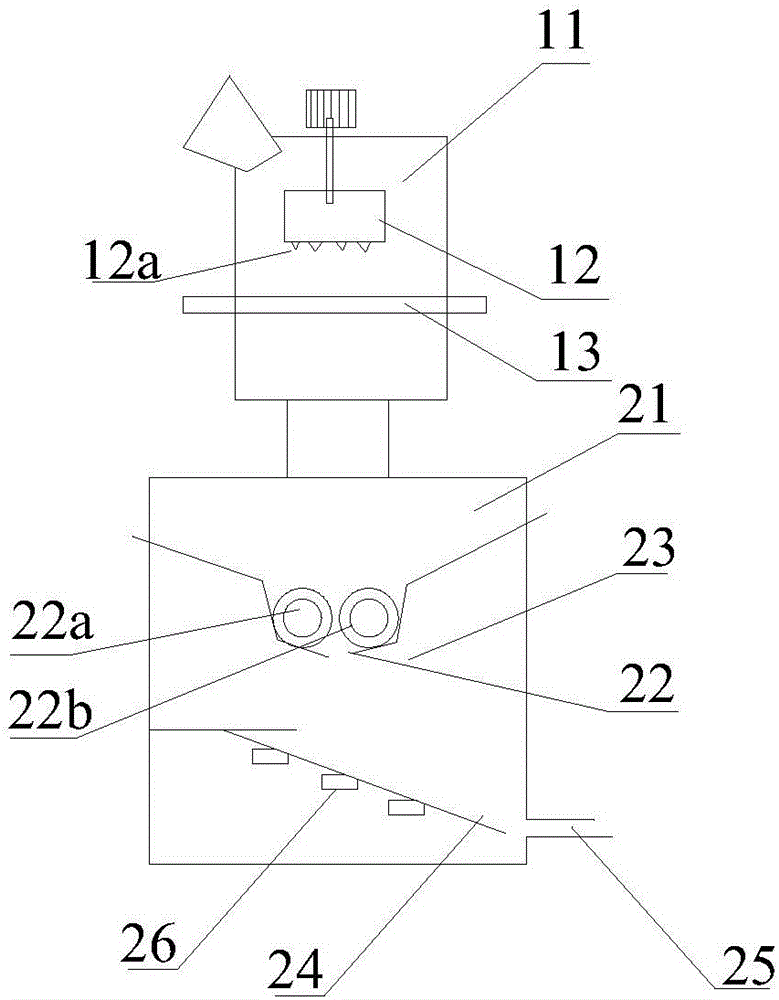

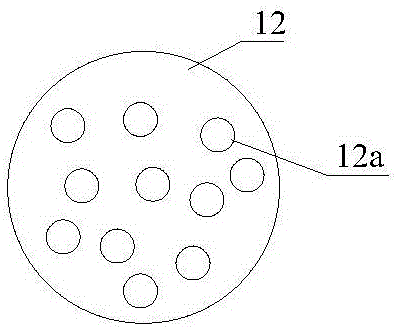

[0021] Please see attached figure 1 , is a schematic diagram of an embodiment of the ore crushing device provided by the present invention, specifically including a crusher box 11, a gravity hammer 12 is arranged in the crusher box, and a load-bearing plate 13 is arranged below the gravity hammer 12. The load-bearing plate is provided with sieve holes. In order to better crush the ore materials, a plurality of crushing cones are provided on the lower end surface of the gravity hammer provided by the present invention. Please also refer to figure 2 , the crushing cone is conical or pyramidal, and the present invention is not particularly limited thereto, preferably conical. The crushing cone can be machined on the gravity hammer, or directly fixed under the gravity hammer.

[0022] Due to the arrangement of the crushing cone, the gravity hammer can achieve better crushing effect during the reciprocating motion. There is a feeding port on the top of the crusher box. In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com