Preparation and Application of 2-Hydroxymethyl-12-crown Ether-4 Modified Hierarchical Porous Silicon Materials

A multi-level porous, silicon material technology, applied in the direction of silicon compound, polluted waterway/lake/pond/river treatment, other chemical processes, etc. Simple and easy to operate, improve adsorption capacity, high selectivity adsorption separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Preparation of Nanocrystalline Cellulose (NCC)

[0037] Weigh 5 g of absorbent cotton, place it in 75 mL of 1:1 sulfuric acid, control the temperature at 45 °C, and hydrolyze for 2 hours; add a large amount of water to terminate the hydrolysis reaction, and let it stand for 10 hours; then pour off the supernatant, take the lower layer, and Centrifuge to control the volume to less than 130mL; adjust the pH of the solution to 2.4 by dialysis, and set aside.

Embodiment 1

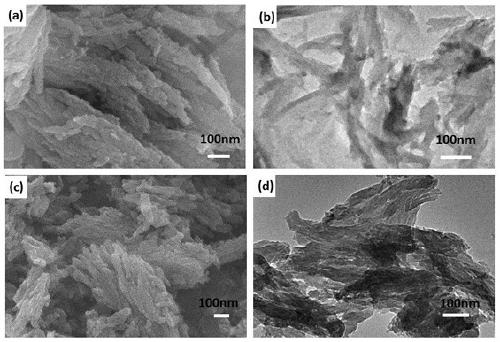

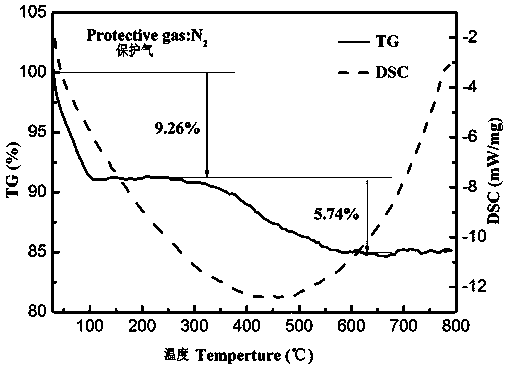

[0039] (1) Dissolve 30 mg of CTAB in a mixed solution of 40 mL of distilled water and 20 mL of ethanol, and stir vigorously at 30 °C for 2 h. Add 400 μL NH 3 ·H 2 O and 4mL of 0.5% NCC (pre-sonicated for 30min), stirred for 10min. Then add 100μL TEOS and stir for 2h. After the reaction, wash twice with distilled water and ethanol alternately, dry at 30°C to obtain a hierarchical porous silicon / NCC composite, and calcinate in a muffle furnace at 540°C for 6 hours to remove NCC and obtain a hierarchical porous silicon material.

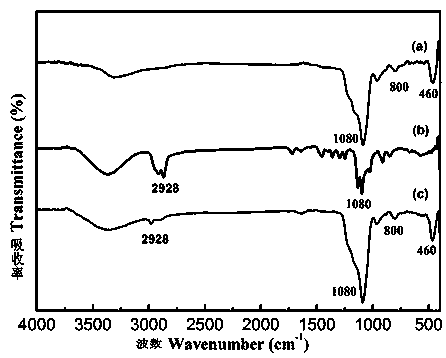

[0040] (2) Take 1 g of the activated hierarchical porous silicon material, add it to 75 mL of dry toluene, add 0.2 mL of 2C12M4 under nitrogen protection for 30 min, and condense and reflux at 80 ° C for 24 h. After the reaction, filter, wash with ethanol three times, and dry at 60°C to obtain the lithium ion adsorption material.

[0041] (3) Add the prepared pure lithium chloride solution into a 10mL colorimetric tube, then add lithium ion adsorpti...

Embodiment 2

[0043] (1) Dissolve 30 mg of CTAB in a mixed solution of 40 mL of distilled water and 20 mL of ethanol, and stir vigorously at 30 °C for 1.5 h. Add 300 μL NH 3 ·H 2 O and 3mL of 0.5% NCC (pre-sonicated for 30min), stirred for 8min. Then add 80μLTEOS, continue to stir for 2h. After the reaction, wash twice with distilled water and ethanol alternately, dry at 30°C to obtain a hierarchical porous silicon / NCC composite, and calcinate in a muffle furnace at 540°C for 6 hours to remove NCC and obtain a hierarchical porous silicon material.

[0044] (2) Take 1 g of the activated hierarchical porous silicon material, add it to 75 mL of dry toluene, add 0.1 mL of 2C12M4 under nitrogen protection for 30 min, and reflux at 80 ° C for 24 h. After the reaction, filter, wash with ethanol three times, and dry at 60°C to obtain the lithium ion adsorption material.

[0045] (3) Add the prepared pure lithium chloride solution into a 10mL colorimetric tube, then add lithium ion adsorption mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com